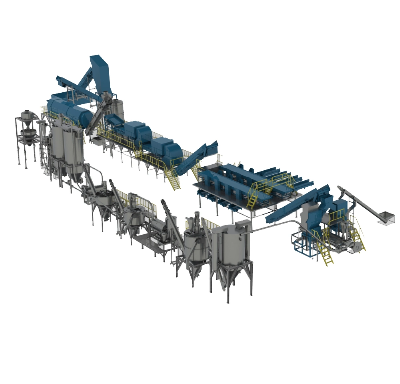

3000 kg/h PET Bottle Washing LinePET bottle recycling system is

used to recycle from PET bottles bales to PET flakes, which with

big capacity from 500 kg/h to 9000 kg/h.This process of washing and

crushing is consist of different function units. The final product

rPET flakes has a stable quality and various grade

applications, especially for PSF ,POY manufacturer with big

capacity. Recent year, BoReTech develop new technology, rPET can be

achieved Bottle-to Bottle grade application with FDA

approval.Description: The Process is used to recycle big

capacity and stable quality raw material, especially for PSF

manufacturer and recycled POY manufacturer with big

capacity. Specification: Power: ~380 KWCapacity:

3 Mt/hour InputArea Requirement: 1000m2Advantage of PET Bottle

Washing Line by BoReTech- Food grade PET bottle washing line

supplier in Asia;- Greater capacity - Greater than 6t/hr input

capacity of PET bottle recycling system with full automation and

intelligentialize;- Water saving -provide waste water treatment to

decrease water consumption to be lower than 1 liter for each ton of

PET flake;-Optional Functional Unit for your choice:1.Automatic

Detergent Dosing System:In-line real-time monitoring,save

manpower.2.Online Water Saving System:Save water consumption.3.PET

Fines Purification:High speed centrifugation,multi-step

separation,capacity:500 KG/H.4.Tntegrated Automation:Monitor all

machine running statuses and conditions,fix any equipment problem

in a timely manner and enhances plant safety and control

stability.Process Flowchart: De-baling----- Label

Scrapping------ Label Separation------- Bottle

Pre-washing--------Manual Sorting and Metal Detecting-----Wet

Grinding-------Gravity Separation-------Chemical Washing for PET

Flakes-------Rinsing--------Drying--------PackingComposition of PET

Bottle Bale:DescriptionCharacteristicPET ContainersOne-way

bottlesColors FractionPET bottles should be pre-sorted by color. If

the percentage of color bottles is higher than 30%, we suggest

customer to install the automatic color bottle sorting machine to

achieve efficiency.Base CupsIncluded, if any, and should be PP or

PE plastic.Labels(shrunk or glued)The production line is designed

for removing label mechanically. All type of labels will be removed

by mechanical action. It includes paper, BOPP, PET, PVC,

etc.CapsPP, HDPECaps sealsEVA, PP ( floatable material )PVC or

rubber seals are not separable.GlueHot melt, water

borne.ContaminationMixed with the bottles could be present

contaminations coming from the collection and storage of the

postconsumer bottles or made by consumer. These contaminations

include mud, sand, soil, glass, organics, paper, residual liquid,

etc.Total contamination content should not exceed 10%.Total

Non-PETContainersNon-PET containers max 2% of whichPVC Container0.5

-1% maxPolyolefins Container3 % max. It will only affect the output

volume but not quality of end product.Wrong PET Colorsand

Opaque1-2% maxGlass and Ceramic (metals excluded)0.5 -1%

maxMagnetic Metals0.5 - 1% maxAluminum and Non Magnetic Metals0.5 -

1% maxAll kind of metal will be separated before

crushing Section introduction of PET bottle washing line1.

De-baling SectionDe-baling unit adopts weighing-connected

feeding device by high automation technology and break up bottle

bales and remove mixed metal. The special knife structure can avoid

any unexpected mechanical clogging.2. Sieving Section Sieving

unit including dry trommel, disk screener and metal removal device

to separate some big impurities such as mud, sands and metals from

PET bottles and flakes. Meanwhile, through digital technology likes

metal detector, pipe-type metal separator, metals can be separated

automatically by flapping device to reduce inline manpower.

Besides, belt-type metal separator can reach the same

function.3.Label Separation SectionThis label separation unit is

mainly designed for heat shrinkage label removal.Label separation

unit from BoReTech has two types. One consists of patented label

scrapping machine and label blowing machine which wind-force is

adjustable. When facing limited space, the new design of compact

label remover is also a good choice to scrap heat shrinkage labels

and separate them by one machine.4.Bottle Pre-washing SectionThe

primary features of this process are the automated water

circulation system, continuous feeding and washing. This system

uses special designed inner structure to cause friction for PET

bottles inside the machine to remove most of adhesive labels, and

uses the high-temperature chemical water to remove dirt, sands,

glues, rubbers, metal and other impurities on the surface of

bottles.5.Floatation SectionSecondary washing of PET flakes after

crushing is very important. Floatation unit separates PO& PP/PE

caps which density is below 1 by using water as the separation

media. This unit is comprised by floatation washing and packing

silo. It's good to remove caps, rings to keep flakes with stable

quality. And impuri

Related products about PET Bottle Recycling Line (TL3000) Washing Line

-

Waste Tyre Plastic Recycling Machinery Machine Tire Crusher Production Line Rubber Crumb Grinding Machine Equipment Tire Shredder

Waste Tyre Plastic Recycling Machinery Machine Tire Crusher Production Line Rubber Crumb Grinding Machine Equipment Tire Shredder

-

Stretch Plastic Blowing Pet Bottle Making Blow Molding Machine Bottles Stretch Automatic Pet Bottle Blowing Machine

Stretch Plastic Blowing Pet Bottle Making Blow Molding Machine Bottles Stretch Automatic Pet Bottle Blowing Machine

-

Waste Plastic Pet Bottle, Water Bottle Flake, PP/HDPE/LDPE PE Film Jumbo Woven Bags Plastic Crusher Machine, Plastic Crushing Washing Recycling Machine

Waste Plastic Pet Bottle, Water Bottle Flake, PP/HDPE/LDPE PE Film Jumbo Woven Bags Plastic Crusher Machine, Plastic Crushing Washing Recycling Machine

-

Type 2 Wall-Mounted Electric Car Charging Station 7kw /11 Kwelectric Vehicle Charging Station Home Wallbox AC EV Charger Single Phase or 3three Phase

Type 2 Wall-Mounted Electric Car Charging Station 7kw /11 Kwelectric Vehicle Charging Station Home Wallbox AC EV Charger Single Phase or 3three Phase

-

G-View G12W Wholesale Auto Car LED Headlight Bulb High Power H13 H11 9005 H7 H4 Car LED Headlights LED Car Lights

G-View G12W Wholesale Auto Car LED Headlight Bulb High Power H13 H11 9005 H7 H4 Car LED Headlights LED Car Lights

-

New Design Porcelain Round Plates Dinner Set for Wedding and Banquet

New Design Porcelain Round Plates Dinner Set for Wedding and Banquet

-

China 2023 New Design Super Soft 100% Polyester Microfiber Knitted Oversized Decoration Hoodie Blanket

China 2023 New Design Super Soft 100% Polyester Microfiber Knitted Oversized Decoration Hoodie Blanket

-

Handmade Art Creative Materials Thickened White Paper Cup DIY Disposable Handmade Colored Paper Cup

Handmade Art Creative Materials Thickened White Paper Cup DIY Disposable Handmade Colored Paper Cup