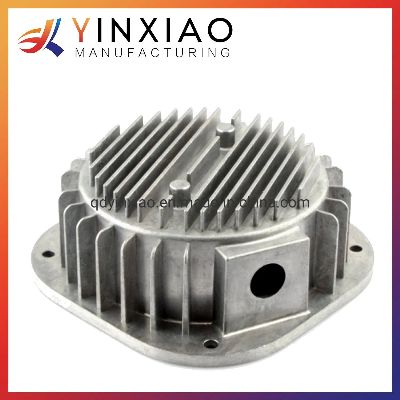

Product DescriptionDie casting is a metal

casting process that is characterized by

forcing molten metal under high pressure into

a mold cavity. The mold cavity is created using two

hardened tool steel dies which have been machined

into shape and work similarly to an injection mold during

the process. Most die castings are made from non-ferrous

metals,

specifically zinc, copper, aluminium, magnesium, lead, pewter,

and tin-based alloys. Depending on the type of metal being

cast, a hot- or cold-chamber machine is used.The casting equipment

and the metal dies represent large capital costs and this tends to

limit the process to high-volume production. Manufacture of parts

using die casting is relatively simple, involving only four main

steps, which keeps the incremental cost per item low. It is

especially suited for a large quantity of small- to medium-sized

castings, which is why die casting produces more castings than any

other casting process.[1] Die castings are characterized by a

very good surface finish (by casting standards) and

dimensional consistency. Detailed PhotosDie and component

material and hardness for various cast metals Die

componentCast metalTin, lead & zincAluminium & magnesiumCopper &

brassMaterialHardnessMaterialHardnessMaterialHardnessCavity

insertsP20290-330 HBH1342-48 HRCDIN 1.236738-44

HRCH1146-50 HRCH1142-48 HRCH20, H21, H2244-48 HRCH1346-50

HRC CoresH1346-52 HRCH1344-48 HRCDIN

1.236740-46 HRC DIN 1.236742-48 HRC Core

pinsH1348-52 HRCDIN 1.2367 prehard37-40 HRCDIN 1.2367

prehard37-40 HRCSprue partsH1348-52 HRCH13DIN 1.236746-48 HRC44-46

HRCDIN 1.236742-46 HRCNozzle42040-44 HRCH1342-48 HRCDIN

1.2367H1340-44 HRC42-48 HRCEjector pinsH1346-50 HRCH1346-50

HRCH1346-50 HRCPlunger shot sleeveH1346-50 HRCH13DIN 1.236742-48

HRC42-48 HRCDIN 1.2367H1342-46 HRC42-46 HRCHolder block4140

prehard~300 HB4140 prehard~300 HB4140 prehard~300 HBProduct

ParametersProduct

Specifications: Material:Aluminum, A380, A356, ADC12,

AlSi10Mg, 104, 102 etc.Dimension:According to the drawing or

sampleStandard:DIN GB ISO JIS BA ANSICasting

equipment:80T/160T/250T/300T/500Tcasting machine,Sand blasting

machine,5T electri stove,Metallographic detector,Independent mould

manufacturingProduction Process:Polish/Sand

Blast/EDM/Milling/Texture/Grind/Pre-Treatment/Quenching/Lathe/Wire

Cut/Annealing/Temper etc.Equipment of Casting:1. High pressure die

casting machining:125T/180T/250T/280T/500T/800T/1250T2. Gravity

casting machine: 5 production lines3. Low pressure die casting

machining: 1 production line4. Sand casting machine: 6 production

lines5. Degassing equipment and opportunities to refine the

material6. Machining: 5Sets CNC Machines;3 sets Milling machines; 3

setsTurning machines; 10 sets drill and tap

machinesCertificationsPackaging & ShippingCompany ProfileYinxiao

Manufacturing provides you with one-stop service from Raw materials

→ Precision Investment casting, Lost wax casting, Sand casting, Die

casting, Centrifugal casting, Sheet metal Stamping → Rapid tooling

→ CNC Machining → Surface Treatment → Quality Inspection → Timely

delivery to customersWHAT WE DO:* Casting parts (Steel, stainless

steel, carbon steel, Iron, gray iron, ductile iron, Aluminum,

aluminum alloy, Copper, brass, copper alloy, etc.);* CNC Machining

(Machining Center, Turning, Milling, Planing, Grinding, Drilling,

etc);* Sheet metal (Stamping, Laser Cutting, Bending, Welding);*

Plastic injection (polystyrene (PS), polyvinyl chloride (PVC),

polyethylene (PE), polypropylene (PP), polymethyl methacrylate

(PMMA), etc.);* Surface treatment (sandblasting, shot blasting,

painting, spraying, electrophoresis, anodizing, polishing,

electroplating, etc.); Our AdvantagesAdvantages and

disadvantages: Excellent dimensional accuracy (dependent on

casting material, but typically 0.1 mm for the first

2.5 cm (0.004 inch for the first inch) and 0.02 mm

for each additional centimeter (0.002 inch for each additional

inch).Smooth cast surfaces (Ra 1-2.5 micrometres or 0.04-0.10

thou rms).Thinner walls can be cast as compared to sand and

permanent mold casting (approximately 0.75 mm or

0.030 in).Inserts can be cast-in (such as threaded inserts,

heating elements, and high strength bearing surfaces).Reduces or

eliminates secondary machining operations.Rapid production

rates.Casting tensile strength as high as 415 megapascals

(60 ksi).Casting of low fluidity metals.The main disadvantage

to die casting is the very high capital cost. Both the casting

equipment required and the dies and related components are very

costly, as compared to most other casting processes. Therefore, to

make die casting an economic process, a large production volume is

needed. Other disadvantages are that the process is limited to

high-fluidity metals, and casting weights must be between

30 grams (1 oz) and 10 kg (20 lb).[note

3][10] In the standard die casting process the final casting

will have a small amount of porosity. This prevents any heat

treating or welding, because the heat causes the ga

Related products about Custom Precision Die Casting Part with Aluminum CNC Machining Motorcycle Accessories/Auto Parts/Heat Sink Bracket/Chair Base Die Casting Part

-

Waste Tyre Plastic Recycling Machinery Machine Tire Crusher Production Line Rubber Crumb Grinding Machine Equipment Tire Shredder

Waste Tyre Plastic Recycling Machinery Machine Tire Crusher Production Line Rubber Crumb Grinding Machine Equipment Tire Shredder

-

Stretch Plastic Blowing Pet Bottle Making Blow Molding Machine Bottles Stretch Automatic Pet Bottle Blowing Machine

Stretch Plastic Blowing Pet Bottle Making Blow Molding Machine Bottles Stretch Automatic Pet Bottle Blowing Machine

-

Waste Plastic Pet Bottle, Water Bottle Flake, PP/HDPE/LDPE PE Film Jumbo Woven Bags Plastic Crusher Machine, Plastic Crushing Washing Recycling Machine

Waste Plastic Pet Bottle, Water Bottle Flake, PP/HDPE/LDPE PE Film Jumbo Woven Bags Plastic Crusher Machine, Plastic Crushing Washing Recycling Machine

-

Type 2 Wall-Mounted Electric Car Charging Station 7kw /11 Kwelectric Vehicle Charging Station Home Wallbox AC EV Charger Single Phase or 3three Phase

Type 2 Wall-Mounted Electric Car Charging Station 7kw /11 Kwelectric Vehicle Charging Station Home Wallbox AC EV Charger Single Phase or 3three Phase

-

G-View G12W Wholesale Auto Car LED Headlight Bulb High Power H13 H11 9005 H7 H4 Car LED Headlights LED Car Lights

G-View G12W Wholesale Auto Car LED Headlight Bulb High Power H13 H11 9005 H7 H4 Car LED Headlights LED Car Lights

-

New Design Porcelain Round Plates Dinner Set for Wedding and Banquet

New Design Porcelain Round Plates Dinner Set for Wedding and Banquet

-

China 2023 New Design Super Soft 100% Polyester Microfiber Knitted Oversized Decoration Hoodie Blanket

China 2023 New Design Super Soft 100% Polyester Microfiber Knitted Oversized Decoration Hoodie Blanket

-

Handmade Art Creative Materials Thickened White Paper Cup DIY Disposable Handmade Colored Paper Cup

Handmade Art Creative Materials Thickened White Paper Cup DIY Disposable Handmade Colored Paper Cup