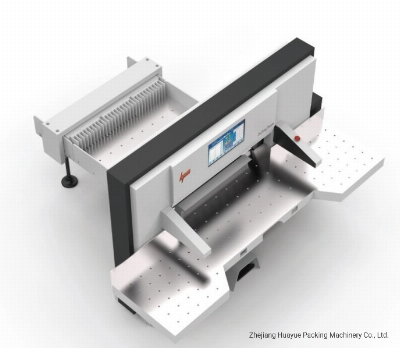

HPM137S22 Program Control Paper Cutter Computer

System1. The up-to-date 22" Widescreen LCD, full touch screen; PLC

control.2. Eight languages to choose.3. Metric system and British

system two units, show the dimensions of the front knife and the

back knife. 4. Step less speed adjustment function with latest

technology , to make the cutting speed from 30 to 48 times within 1

minute , no need to change knife angle for different cutting

material.5. Position resolution of backgauge is 0.01mm, closed-loop

control, the locating error is less 0.01mm; No need to adjust

locating error. Max. backgauge speed is 30-38m/min. 6. The

program storage capacity is 300 programs. Every program can store

299 items cutting sizes. The storage memory has a maximum of 40

years.7. With USB, transmit data, to convenient operator make

programming and arrangement via PC. 8. Equipped with fault

diagnostics and non-repeat safety guards.it can detect all the

position switch state and dynamic prompt switch failure.make

the machine more convenient maintenance.9. The backgauge is driven

by a Panasonic servo-motor with four speed levels.10. Use Italy oil

pump and hydraulic system.11. With automatic pushing paper

function, the distance can be adjusted.12. Adjustable time delay

for knife activation, accurate and convenient.13. Uses icons to

show operational functions, which are simple and user friendly.14.

With full automatic cutting function. The backgauge and knife

movements can be monitored on the screen.

Machine Performance1. Knife-seat guiding structure with sliding

block type, cam type for adjusting-knife mechanism.2. Clamp press

paper stack through hydraulic system, the spring re-position.3.

Worm gear drive mechanism, hydraulic clutch, mechanical brake.4.

Hydraulic system adopts Germany advanced technology, the hydraulic

units are ISO approved, Italy oil pump.5. One-piece, slot less and

chrome-plated cast iron work table is sturdy and easy to

maintain.6.Import ball screw with double linear guides to drive

backgauge.7.High safety infrared protection device according to CE

standard.8.Main electronic units are from French TE and Japanese

ORMON famous international brands.

Configuration ListingNoNameBrand, specification &

modelOrigin of brand1.Background LCD22''Color touch

InterfaceChina2.Control center PLC (CPU224)China3.Backgauge

position motorINOVANCE servo

motorJapan4.Pick-upAutonicsKorea5.Limit switchTEFrance6.Guarding

motorTEFrance7.Air switchTEFrance8.AC ContactorTEFrance9.Miniature

relayOMRONJapan10.Switching power supplyTEFrance11.Power

switchMoellerGermany12.Ball screwHigh accurateTaiwan13.Linear

guiderHigh accurate double linear guidesTaiwan14.Hydraulic

systemDouble gear pumpItaly15.BearingNSKJapan16.Work TableSlotless

and plated chromium work tableChina17HSS knifeKanefusaJapan

Technical ParameterModelUnit137Max.Cutting

Widthcm137 inch53.9Max.Cutting Lengthcm145 inch57.1Max.

Cutting Heightmm165 inch6.5Min. Cutting Size(without false

clam pplate)mm30 inch1.2Min. Cutting Size(with false clamp

plate)mm90 inch3.5Front Table

Lengthcm73 inch28.7Max.Clamp PressureN45000Max. Cutting

Speedtime/min43Main MotorKW4Net WeightKg4100Gross

WeightKg4500Packing Size(L×W×H)cm310×190×210/* March 10, 2023

17:59:20 */!function(){function s(e,r){var

a,o={};try{e&&e.split(",").forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

Related products about Program Control Heavy Duty Paper Cutting Machine for Printing

-

Waste Tyre Plastic Recycling Machinery Machine Tire Crusher Production Line Rubber Crumb Grinding Machine Equipment Tire Shredder

Waste Tyre Plastic Recycling Machinery Machine Tire Crusher Production Line Rubber Crumb Grinding Machine Equipment Tire Shredder

-

Stretch Plastic Blowing Pet Bottle Making Blow Molding Machine Bottles Stretch Automatic Pet Bottle Blowing Machine

Stretch Plastic Blowing Pet Bottle Making Blow Molding Machine Bottles Stretch Automatic Pet Bottle Blowing Machine

-

Waste Plastic Pet Bottle, Water Bottle Flake, PP/HDPE/LDPE PE Film Jumbo Woven Bags Plastic Crusher Machine, Plastic Crushing Washing Recycling Machine

Waste Plastic Pet Bottle, Water Bottle Flake, PP/HDPE/LDPE PE Film Jumbo Woven Bags Plastic Crusher Machine, Plastic Crushing Washing Recycling Machine

-

Type 2 Wall-Mounted Electric Car Charging Station 7kw /11 Kwelectric Vehicle Charging Station Home Wallbox AC EV Charger Single Phase or 3three Phase

Type 2 Wall-Mounted Electric Car Charging Station 7kw /11 Kwelectric Vehicle Charging Station Home Wallbox AC EV Charger Single Phase or 3three Phase

-

G-View G12W Wholesale Auto Car LED Headlight Bulb High Power H13 H11 9005 H7 H4 Car LED Headlights LED Car Lights

G-View G12W Wholesale Auto Car LED Headlight Bulb High Power H13 H11 9005 H7 H4 Car LED Headlights LED Car Lights

-

New Design Porcelain Round Plates Dinner Set for Wedding and Banquet

New Design Porcelain Round Plates Dinner Set for Wedding and Banquet

-

China 2023 New Design Super Soft 100% Polyester Microfiber Knitted Oversized Decoration Hoodie Blanket

China 2023 New Design Super Soft 100% Polyester Microfiber Knitted Oversized Decoration Hoodie Blanket

-

Handmade Art Creative Materials Thickened White Paper Cup DIY Disposable Handmade Colored Paper Cup

Handmade Art Creative Materials Thickened White Paper Cup DIY Disposable Handmade Colored Paper Cup