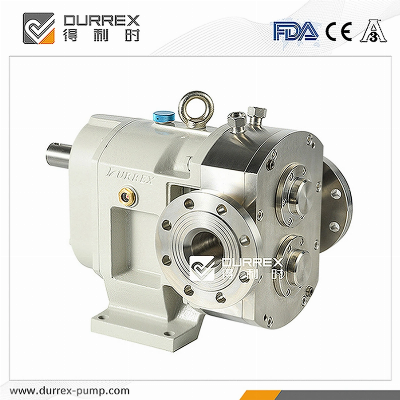

Paper Pulp Transfer Rotary Lobe Pump With High Efficiency and

High QualityDifferent structure and material of mechanical

seal for paper coating, can extend service life of seal.Paper

making lobe pumps are widely used to transfer PAM, starch slurry,

liquid rosin, rosin gum. paper slurry, dry-strength agent,

wet-strength agent, sizing agent, defoaming agent, coloring starch,

coating and so on.We have more than 60 domestic and foreign paper

industry users, more than three thousand rotary pumps are procured

for use in paper making industry. Such as UPM, ECOLAB, GAW, Stora

Enso, Kemira, ASIA Symbol, Nine Dragons Paper, OJI paper, Lee & Man

paper, APP paper...... Now, we have a very mature R & D technology

and application technology,Lobe pump is very well used in the

industry and it has gradually replaced the screw pump in many

working conditions of paper making industry. Lobe pump maily used

following positions.Preparation of starch glue and feeding and

conveying of starch.----S.S. lobe pumpCoating preparation and

coating feeding and transportation.----S.S. lobe pumpChemical

unloading and chemical addition.----S.S. lobe pump Product

features:1. Gap is kept between the rotors and rotors & pump body,

no friction, long using-life. 2. Simple assembling and

disassembling, easy to maintenance and clean, less easily-damaged

parts. 3. High efficiency and energy-saving, low failure,

reliable sealing and low noise. 4. In the same type

pump, different type rotor can be interchanged.5. Capable to pmp

the viscous medium from 1cp to 2million cps. 6. Capable of

pumping mixture of gas, fluid and solid medium. 7. Equipped

with inverter, the flow can be adjusted as requirement of end-user.

8. Flange, screw or clamp connection can be selected as

required. 9. Higher hygienic grade, support CIP, SIP. The

surface roughness is 0.2--0.8um, got 3A, FDA certification.

10. Hygienic safety valve is built-in structure.

Structure drawing and main material

DescriptionMaterialQuantityPump cover304 /304L /316 /316L1Pump

body304 /304L /316 /316L1RotorRubber /304 /304L /316 /316L2Main

shaft316-316L /42CrMo1Sub-shaft316-316L /42CrMo1Mechanical seal

seat304 /304L /316 /316L2Mechanical sealSIC /Tungsten

carbide2O-ringFKM /FFKM/ EPDM /TFE /PTFE,etc.1Rotor lock nut304

/304L /316 /316L2Lip sealNBR /FKM3Working Principle of

Lobe PumpTwin-Rotary pumps are multi-functional and bi-directional

positive displacement pumps, produced with fine technology. The

manufacturing engineering and precision of the pumps approach the

advanced level of the world. Rotary pumps use synchronic rotors,

driven by a pair of synchronic gears in the gear box. Transmitted

by the main shaft and the sub-shaft. The rotors move synchronically

in counter-clockwise directions, which, consequently, varies the

pump capacity and builds up high vacuum capacity and emission

pressure. It is particularly suitable to pump sanitary medium,

high-corrosive and high-viscous medium. Technical

parametersTypeCapacity fortri-imepller rotor(L/r)Rotation

speed(r/min)Flow(m3/h)Discharge Pressure(MPa)Standard I& O

DN(mm)Enlarged I& O DN(mm)WeightBare

pump(kgs)15TLS12-0.5C0.0410-7200.51.215253025TLS12-2C0.1510-72021.225404040TLS12-5C0.3210-50051.240505050TLS12-10C0.6510-500101.250658060TLS12-15C1.110-500151.2658012065TLS12-20C1.7410-500201.2658020075TLS12-30C2.610-500301.28010023080TLS12-40C3.6510-500401.2100125260100TLS12-60C5.210-500601.2125150400125TLS12-80C6.810-500801.2125150450140TLS12-120C9.810-4001201.2150200600150TLS12-150C12.810-4001501.2150200680200TLS12-200C1610-3002001.2200250780250TLS12-300C2010-3003001.2250300900300TLS12-400C3010-3004001.23003501100........................

Installation drawing and

weightHorizontalTypeAAABBBCDEFMNstandard sealwater flush

seal15TLS12-0.5C1401706799.541.5 Φ17209251425TLS12-2C18522010814450.561.5Φ225098618.540TLS12-5C210240114154.56071Φ285011182450TLS12-10C2462841251757182Φ385013010

Related products about Paper Pulp Transfer Rotary Lobe Pump with High Efficiency and High Quality

-

Waste Tyre Plastic Recycling Machinery Machine Tire Crusher Production Line Rubber Crumb Grinding Machine Equipment Tire Shredder

Waste Tyre Plastic Recycling Machinery Machine Tire Crusher Production Line Rubber Crumb Grinding Machine Equipment Tire Shredder

-

Stretch Plastic Blowing Pet Bottle Making Blow Molding Machine Bottles Stretch Automatic Pet Bottle Blowing Machine

Stretch Plastic Blowing Pet Bottle Making Blow Molding Machine Bottles Stretch Automatic Pet Bottle Blowing Machine

-

Waste Plastic Pet Bottle, Water Bottle Flake, PP/HDPE/LDPE PE Film Jumbo Woven Bags Plastic Crusher Machine, Plastic Crushing Washing Recycling Machine

Waste Plastic Pet Bottle, Water Bottle Flake, PP/HDPE/LDPE PE Film Jumbo Woven Bags Plastic Crusher Machine, Plastic Crushing Washing Recycling Machine

-

Type 2 Wall-Mounted Electric Car Charging Station 7kw /11 Kwelectric Vehicle Charging Station Home Wallbox AC EV Charger Single Phase or 3three Phase

Type 2 Wall-Mounted Electric Car Charging Station 7kw /11 Kwelectric Vehicle Charging Station Home Wallbox AC EV Charger Single Phase or 3three Phase

-

G-View G12W Wholesale Auto Car LED Headlight Bulb High Power H13 H11 9005 H7 H4 Car LED Headlights LED Car Lights

G-View G12W Wholesale Auto Car LED Headlight Bulb High Power H13 H11 9005 H7 H4 Car LED Headlights LED Car Lights

-

New Design Porcelain Round Plates Dinner Set for Wedding and Banquet

New Design Porcelain Round Plates Dinner Set for Wedding and Banquet

-

China 2023 New Design Super Soft 100% Polyester Microfiber Knitted Oversized Decoration Hoodie Blanket

China 2023 New Design Super Soft 100% Polyester Microfiber Knitted Oversized Decoration Hoodie Blanket

-

Handmade Art Creative Materials Thickened White Paper Cup DIY Disposable Handmade Colored Paper Cup

Handmade Art Creative Materials Thickened White Paper Cup DIY Disposable Handmade Colored Paper Cup