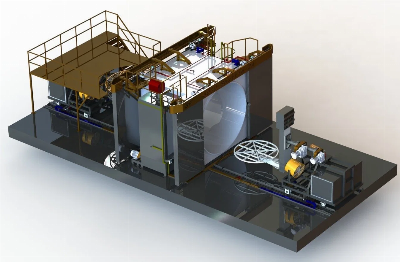

Product IntroductionShuttle style rotational molding machine is

placed along a straight line with oven and two mainframes in

its center. Cooling chamber and loading station in both sides.

When one arm on one side rotating the mold into

the oven to get heated, the molds on other arm

can be demoulded or adding material.In this way, the operation

is flexiable for manufacturing comparatively large product. Even

for comparatively small product, productivity is high.

Besides, equipment is relatively simple and easy to be maintained.

At present, this kind of rotational molding machine is broadly used

in our country.Technical parameters Model No.Oven

Size(mm)Machine Dimensions(mm)Total Power(kw)Total

weight(Ton)LWHBF-1600CSØ1600750035002600105BF-2000CSØ2000950045003100158BF-2500CSØ250012000600038002510BF-3000CSØ300013500700043003212BF-3500CSØ350015000800048004015BF-4000CSØ400017000900054004018BF-4500CSØ4500185001000060005022BF-5000CSØ5000205001100062005025Machinery

type:Shuttle rotomolding machineHeating supply:Natural

gas,liquefied gas,diesel oilTemperature control:DTE

Control±2ºCBurner system:RielloCooling mode:Fan coolingControl

mode:Touch screen+PLC(Siemens brand)Electric

brand:Schneider,OmronDelivery time:About 60 days after receive the

depositOverseas Installation periodIt depends on machine

size,usually takes 10-20daysHeating rate:3 miniutes from room

temperature to 280 degree in ovenBenfan rotomolding machine

advantage:1. It only takes 3mins. from room

temperature increase to 250 to 280 degree in

oven2. Arm is made of special alloy material

which is good load3. Full gear transmission, high

efficiency4. Full automatic

operation5. Heavy duty oven and energy

saving6. Loading and unloading easy for

mould7. Special deep cavity heating technical,

suitable for complicated product8. Internet

remote control (if the machine has problem in your factory, we can

solve the problem through internet) 9. PLC and

Motors are Siemens brand from German,Burner is RIELLO from

Italy,Bearing is NSK from Japan, all electrial compenents are using

Schneider brand.10. Big computer screen, bob-weight system,

special made motor, thermostability sealing arm

head etc11. Use circle oven, it is more uniform heat

distribution on the mold, that means it is good for product making

and also more energy saving.Quick DetailsQ1. What is your company

main products?A:Our company is mainly producing rotational molding

machine, mold and cooler box.Q2. What is the MOQ for your

production?A:For rotomolded cooler,the MOQ is 50pcs;sample is

available,only undertake sample cost and courier fee.We will return

the sample cost when you place order.Q3. What is your payment

terms?A:Machine&mold:50% deposit TT transfer after sign

contract, and balance 50% after inspection before shipment.Cooler

box:30% deposit TT transfer and balance upon Bill of Lading

copy.Q4. What is your delivery date? A:For machine, usually Within

60 working days upon receipt of deposit TT transfer.For cooler box,

within 20-30 working days for one 40HQ after receive depositQ5.

TransportationA:From Shanghai or Ningbo port by sea or by airQ6.

How about your after-sale services? A:Machine Warranty:one year

after installation and adjustment for trial in customer's workshop.

We will assign two engineers to help customer assemble and trial

run the machine.Cooler box warranty: we will compensate a new one

in your next order.Q7. Do you test all your goods before

delivery?A: Yes, we test 100% of machine by our engineers before

leave our company /* March 10, 2023 17:59:20

*/!function(){function s(e,r){var

a,o={};try{e&&e.split(",").forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

Related products about Shuttle Rotational Molding Machine Energy Saving and Efficient Plastic Products Making Machine 2 Arm Rotomolding Machine with CE Certificate

-

Waste Tyre Plastic Recycling Machinery Machine Tire Crusher Production Line Rubber Crumb Grinding Machine Equipment Tire Shredder

Waste Tyre Plastic Recycling Machinery Machine Tire Crusher Production Line Rubber Crumb Grinding Machine Equipment Tire Shredder

-

Stretch Plastic Blowing Pet Bottle Making Blow Molding Machine Bottles Stretch Automatic Pet Bottle Blowing Machine

Stretch Plastic Blowing Pet Bottle Making Blow Molding Machine Bottles Stretch Automatic Pet Bottle Blowing Machine

-

Waste Plastic Pet Bottle, Water Bottle Flake, PP/HDPE/LDPE PE Film Jumbo Woven Bags Plastic Crusher Machine, Plastic Crushing Washing Recycling Machine

Waste Plastic Pet Bottle, Water Bottle Flake, PP/HDPE/LDPE PE Film Jumbo Woven Bags Plastic Crusher Machine, Plastic Crushing Washing Recycling Machine

-

Type 2 Wall-Mounted Electric Car Charging Station 7kw /11 Kwelectric Vehicle Charging Station Home Wallbox AC EV Charger Single Phase or 3three Phase

Type 2 Wall-Mounted Electric Car Charging Station 7kw /11 Kwelectric Vehicle Charging Station Home Wallbox AC EV Charger Single Phase or 3three Phase

-

G-View G12W Wholesale Auto Car LED Headlight Bulb High Power H13 H11 9005 H7 H4 Car LED Headlights LED Car Lights

G-View G12W Wholesale Auto Car LED Headlight Bulb High Power H13 H11 9005 H7 H4 Car LED Headlights LED Car Lights

-

New Design Porcelain Round Plates Dinner Set for Wedding and Banquet

New Design Porcelain Round Plates Dinner Set for Wedding and Banquet

-

China 2023 New Design Super Soft 100% Polyester Microfiber Knitted Oversized Decoration Hoodie Blanket

China 2023 New Design Super Soft 100% Polyester Microfiber Knitted Oversized Decoration Hoodie Blanket

-

Handmade Art Creative Materials Thickened White Paper Cup DIY Disposable Handmade Colored Paper Cup

Handmade Art Creative Materials Thickened White Paper Cup DIY Disposable Handmade Colored Paper Cup