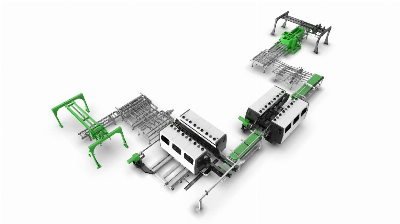

Product Description01 Full-automatic ProfilingThe whole line is

fully automatic production, including the feeding of the incoming

sheet, the transition between the slotting machines and the

finished products02 High speed/High capacityThe longitudinal

no-load speed of high-speed production line can reach 90m/min,

while the current conventional production line speed is only

50-70m/min.03 High stability & Low defective rateHigh precision

tool shaft and cutting tools are used inside the equipment to

ensure stable production and reduce the rate of defective

products.04 Thorough dust controlSlotting equipment is sealed with

a fully closed enclosure, and the dust control rate can reach more

than 95%System

CompositionSawing Machine +Profiling MachineProcessing Length600~2450mmProcessing Width970~1300mmThickness3.0~10.0mmAfter cuttingLength(600~1850mm)×Width (110~475mm)After processing lockLength(600~1850mm)×Width (100~475mm)Feed Drive Unit3.7kW×4P 1 unit Inverter ControlFeeding Speed8 ~40m/min ( With the increase of thickness and Slice number, feed rate decreasing)Caterpillar ChainN75 type Chain×2Caterpillar Chain GuideN75 resin typeMain Spindle22kW×2P 1 unit 3000rpm

Profiling MachineVertical Slotting Machine2.2kW×4P 1 unit Inverter Control,Installed on the Left. 20~90m/min,Ring BeltVertical Double End Milling Rack TruckLeft fixed, right mobile side Installation Liner Guide,Digital, 1.1kw×4P, 1 unitFeed Drive UnitRight mobile side Installation,7.5kW×4P Inverter Control 1 unit 20 ~90m/min(Normal 60m/min)Caterpillar ChainN30 type Chain,2 Column with Urethane Plates(Flat type)Caterpillar Chain GuideN30 ceramic typeAir Blow for ChainRight/Left & Inlet/Outlet, Total 4 pointsLubrication PumpFor Caterpillar Chain Guide, Auto-Lubrication type 25W 1 unit,For Traveling Drive Sleeve & Column Screw.Up Pressing DeviceVapour-pressure type belt pressingSpindle MovementManual type Mechanical digital position indicator

Automation Loading systemOperationControl system1. PLC program controller: Siemens2.Touch Screen: Siemens3.Frequency converter:SiemensServo systemServo motor: SiemensUsing the operating system developed by ourselves, the logic program is rigorous and reasonable.Sensor system1. Photoelectric switch: SICK2. Proximity Switch: SICK3. Magnetic Switch: SMCElectrical control system1. All tests and protection shall adopt double safety protection measures.2. Contactor, intermediate relay: Mitsubishi,Chint Group3. Drag chain cable: GB high-speed flexible sports cable (North American UL standard)Pneumatic control systemVacuum System: Pineb2. Oil-water separator: SMC full pressure automatic drainage type3. Vacuum sucker: self-developed silicone suckerMechanical shifting parametersSheet length: 800~1550 mmSheet width: 800-1250mmSingle weight: maximum 30 KGSinglethickness: 3-8mmMaximumStacking height: 800mmInput gas sourceStable air pressure 0.6-0.8MpaWorking voltageThree phase 380 V, 50 Hz, single phase 220 V, 50 HzWorking heightAccording to the working height of the main engine on site. (900-1250mm)OperationControl system1. PLC program controller: Siemens2.Touch Screen: Siemens3.Frequency converter:SiemensServo systemServo motor: SiemensUsing the operating system developed by ourselves, the logic program is rigorous and reasonable.Sensor system1. Photoelectric switch: SICK2. Proximity Switch: SICK3. Magnetic Switch: SMC

Services ProvidedCompany ProfileFAQQ1: What you can offer to your

customers? A: We can provide our customers with professional

equipment and excellent design and perfect service to ensure their

smooth production.Q2: How long is your delivery time? A:

5-20days after order confirmed.Based on the item and quantity.Q3:

What's the MOQ? A: 1 set.Q4: Can you produce according to

customers' design? A: SureWeare professional manufacturerOEM

AND ODM are both welcome.Q5: Why should I choose your

company? A: We can provide our customers with high auality

and high safety products. We have a team

of experienced skilled workers and engineers.

We can support overseas support. We

can customize the design. We can provide

after-sales service for our customers. /* March 10, 2023

17:59:20 */!function(){function s(e,r){var

a,o={};try{e&&e.split(",").forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

Related products about Starsplas 8 Position Precise Profiling Machine for Spc Production Line

-

Waste Tyre Plastic Recycling Machinery Machine Tire Crusher Production Line Rubber Crumb Grinding Machine Equipment Tire Shredder

Waste Tyre Plastic Recycling Machinery Machine Tire Crusher Production Line Rubber Crumb Grinding Machine Equipment Tire Shredder

-

Stretch Plastic Blowing Pet Bottle Making Blow Molding Machine Bottles Stretch Automatic Pet Bottle Blowing Machine

Stretch Plastic Blowing Pet Bottle Making Blow Molding Machine Bottles Stretch Automatic Pet Bottle Blowing Machine

-

Waste Plastic Pet Bottle, Water Bottle Flake, PP/HDPE/LDPE PE Film Jumbo Woven Bags Plastic Crusher Machine, Plastic Crushing Washing Recycling Machine

Waste Plastic Pet Bottle, Water Bottle Flake, PP/HDPE/LDPE PE Film Jumbo Woven Bags Plastic Crusher Machine, Plastic Crushing Washing Recycling Machine

-

Type 2 Wall-Mounted Electric Car Charging Station 7kw /11 Kwelectric Vehicle Charging Station Home Wallbox AC EV Charger Single Phase or 3three Phase

Type 2 Wall-Mounted Electric Car Charging Station 7kw /11 Kwelectric Vehicle Charging Station Home Wallbox AC EV Charger Single Phase or 3three Phase

-

G-View G12W Wholesale Auto Car LED Headlight Bulb High Power H13 H11 9005 H7 H4 Car LED Headlights LED Car Lights

G-View G12W Wholesale Auto Car LED Headlight Bulb High Power H13 H11 9005 H7 H4 Car LED Headlights LED Car Lights

-

New Design Porcelain Round Plates Dinner Set for Wedding and Banquet

New Design Porcelain Round Plates Dinner Set for Wedding and Banquet

-

China 2023 New Design Super Soft 100% Polyester Microfiber Knitted Oversized Decoration Hoodie Blanket

China 2023 New Design Super Soft 100% Polyester Microfiber Knitted Oversized Decoration Hoodie Blanket

-

Handmade Art Creative Materials Thickened White Paper Cup DIY Disposable Handmade Colored Paper Cup

Handmade Art Creative Materials Thickened White Paper Cup DIY Disposable Handmade Colored Paper Cup