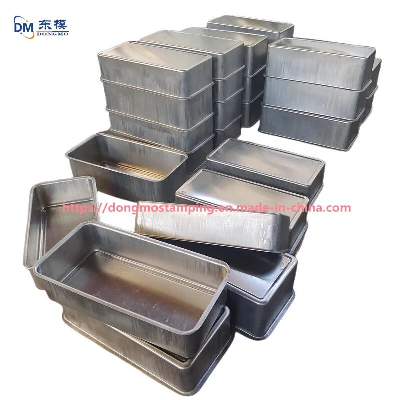

Product Description Product nameAluminum drawing die for sheet

metalProduct materialSKD11, DC53, Cr12MOV, CR12, SKD61, etcDesign

softwareAutoCAD, PRO/E, UG, catia, Dynaform, solidworks, etcDrawing

formatigs,stp,prt,asm,pdf,dwg,dxfApplication

equipmentHydraulic/punch pressPackingMold wooden case or

customStandard partsMISUMIQuantity1 setDetailed PhotosIn the

process of mold manufacturing and stamping of aluminum alloy shell,

the following nine points should be paid attention to:First,

aluminum alloy material is soft, in order to prevent aluminum alloy

deformation and displacement in the process of stamping. Accurate

positioning must be set on the stamping die, the positioning device

requires smooth surface without diamond Angle. This can effectively

reduce the aluminum alloy shell stamping caused by bad.Second, it

is reasonable to design the mold gap, to prevent the aluminum alloy

shell bulge, collapse Angle and other phenomena.Third, in the

design of the structure of the aluminum alloy shell, try to avoid

the appearance of deep holes, because most aluminum alloy shell art

mostly need anodizing, anodizing deep holes easy to hide

acid.Fourth, all the knife edge of the mold should be cut with slow

silk line, because the knife edge of the middle silk line is not

uniform, and the position of the knife edge of the aluminum alloy

shell is prone to burr and dog teeth when stamping.Fifth, aluminum

alloy shell stamping, aluminum alloy plate need to paste PE film.

PE film can effectively reduce scratch and crush.Sixth, in the

production process, to keep the mold, stamping platform, transfer

of plastic plate clean without impurities.Seventh, aluminum alloy

is a good heat conductor, easy conduction and heating. Therefore,

in the process of stamping, it is often necessary to apply aluminum

alloy stamping drawing oil on the material and die for cooling,

which can also play the role of lubrication.Eighth, in the process

of production, if the aluminum alloy shell burrs are too large or

the edge collapses, the mold department should be contacted for

mold repair as soon as possible.Company

ProfileCertificationsPackaging & Shipping FAQ1. What

information should the customer provide to get our accurate

quotation?Customer should provide relevant technical requirements,

drawings, pictures, industrial voltage, planned output, etc.2. What

is the payment period?Payment terms are 40% deposit, 60% before

delivery (T/T model).3. What is the delivery time?Delivery time of

machines is 30-60 days after receipt of deposit.4. Do you test all

the goods before delivery?Yes, we have 100% tests before

delivery.5. Where is your factory?Our factory is located in

Hengshui, Hebei Province, China. Warmly welcome domestic and

foreign customers to visit the field.6. What material is your mold

made of?The materials are D2, YG15, DC53, SKD11, D2, SKH-9 and

SKH-517. What is the biggest pressure in your factory?I plant 25T,

35T, 45T, 60T, 80T, 110T, 160T punch.8. What about the machinery in

your factory?Our factory has a full set of processing equipment,

including large CNC machining center, Sodic EDM machining, imported

EDM-HS, radial drilling machine, milling machine, grinding machine,

three-dimensional testing, etc.9. How does your factory conduct

quality control?Quality comes first. The METS place a strong

emphasis on quality control from start to finish. All of these are

measured periodically by QC using three-dimensional measuring

equipment./* March 10, 2023 17:59:20 */!function(){function

s(e,r){var

a,o={};try{e&&e.split(",").forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

Related products about Professional Aluminum Plate Drawing Die/Aluminum Shell Stamping Die

-

Waste Tyre Plastic Recycling Machinery Machine Tire Crusher Production Line Rubber Crumb Grinding Machine Equipment Tire Shredder

Waste Tyre Plastic Recycling Machinery Machine Tire Crusher Production Line Rubber Crumb Grinding Machine Equipment Tire Shredder

-

Stretch Plastic Blowing Pet Bottle Making Blow Molding Machine Bottles Stretch Automatic Pet Bottle Blowing Machine

Stretch Plastic Blowing Pet Bottle Making Blow Molding Machine Bottles Stretch Automatic Pet Bottle Blowing Machine

-

Waste Plastic Pet Bottle, Water Bottle Flake, PP/HDPE/LDPE PE Film Jumbo Woven Bags Plastic Crusher Machine, Plastic Crushing Washing Recycling Machine

Waste Plastic Pet Bottle, Water Bottle Flake, PP/HDPE/LDPE PE Film Jumbo Woven Bags Plastic Crusher Machine, Plastic Crushing Washing Recycling Machine

-

Type 2 Wall-Mounted Electric Car Charging Station 7kw /11 Kwelectric Vehicle Charging Station Home Wallbox AC EV Charger Single Phase or 3three Phase

Type 2 Wall-Mounted Electric Car Charging Station 7kw /11 Kwelectric Vehicle Charging Station Home Wallbox AC EV Charger Single Phase or 3three Phase

-

G-View G12W Wholesale Auto Car LED Headlight Bulb High Power H13 H11 9005 H7 H4 Car LED Headlights LED Car Lights

G-View G12W Wholesale Auto Car LED Headlight Bulb High Power H13 H11 9005 H7 H4 Car LED Headlights LED Car Lights

-

New Design Porcelain Round Plates Dinner Set for Wedding and Banquet

New Design Porcelain Round Plates Dinner Set for Wedding and Banquet

-

China 2023 New Design Super Soft 100% Polyester Microfiber Knitted Oversized Decoration Hoodie Blanket

China 2023 New Design Super Soft 100% Polyester Microfiber Knitted Oversized Decoration Hoodie Blanket

-

Handmade Art Creative Materials Thickened White Paper Cup DIY Disposable Handmade Colored Paper Cup

Handmade Art Creative Materials Thickened White Paper Cup DIY Disposable Handmade Colored Paper Cup