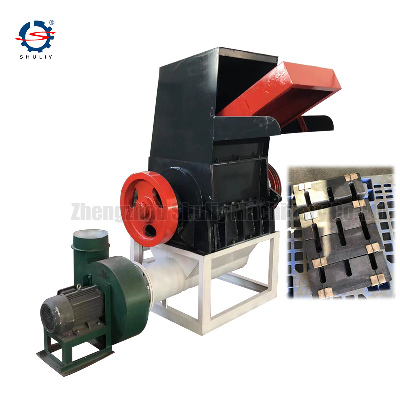

Introduction:Plastic crushers are mainly used to crush various

thermoplastics and rubbers, such as plastic profiles,pipes, rods,

threads, films, and waste rubber products. The pellets can be

directly used for extrusion andinjection molding.Product

Parameters modelsize(mm) length * width *

heightpower(kw)output(kg/h)weight(kg)discharge

size(mm)400900x1100x155011400-600550

6-206001200x1100x175015/18.5600-10008508001750x1550x200030/371000-2000140010001950x1900x225037/452000-3000180012002250x2000x270045/553000-40005500Operation

attention of plastic shredder1. The plastic pulverizer and power

unit should be installed firmly. If the plastic crusher needs to be

fixedfor a long time, it should be fixed on the cement foundation;

if the plastic crusher needs to be flown, theunit should be

installed on the frame made of angle iron, and ensure that the

power engine (diesel engineor electric motor) and plastic The

pulley grooves of the crusher are in the same rotation plane.2.

After the plastic crusher is installed, check the fastening of each

fastener, and tighten it if it is loose. Atthe same time, check

whether the belt tightness is appropriate.3. Before starting the

plastic crusher, first turn the rotor by hand to check whether the

operation of the claws,hammers and the rotor is flexible and

reliable, whether there is any collision in the crushing chamber,

whetherthe rotation direction of the rotor is consistent with the

direction pointed by the machine, and whether thepower machine and

plastic Whether the crusher is in good condition.4. Do not replace

the pulley casually, in case the rotating speed is too high to

cause a crushing chamber, or therotating speed is too low to affect

the working efficiency of the pulverizer.5. After the plastic

shredder is started, it should be kept idling for 2~3 minutes

first, and there is no abnormalphenomenon before feeding work.6.

Pay attention to the operation of the plastic crusher at any time

during the work. First, the feeding should beuniform to prevent the

crushing chamber from being blocked; secondly, do not overload the

work for a long time.If it is found that there is vibration, noise,

high temperature of the bearing and the body, and material spraying

out,it should be stopped immediately for inspection, and the work

can be continued after troubleshooting./* March 10, 2023 17:59:20

*/!function(){function s(e,r){var

a,o={};try{e&&e.split(",").forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

Related products about Automatic Plastic Crusher Recycling Waste Plastic Scrap Crushing Machine

-

Waste Tyre Plastic Recycling Machinery Machine Tire Crusher Production Line Rubber Crumb Grinding Machine Equipment Tire Shredder

Waste Tyre Plastic Recycling Machinery Machine Tire Crusher Production Line Rubber Crumb Grinding Machine Equipment Tire Shredder

-

Stretch Plastic Blowing Pet Bottle Making Blow Molding Machine Bottles Stretch Automatic Pet Bottle Blowing Machine

Stretch Plastic Blowing Pet Bottle Making Blow Molding Machine Bottles Stretch Automatic Pet Bottle Blowing Machine

-

Waste Plastic Pet Bottle, Water Bottle Flake, PP/HDPE/LDPE PE Film Jumbo Woven Bags Plastic Crusher Machine, Plastic Crushing Washing Recycling Machine

Waste Plastic Pet Bottle, Water Bottle Flake, PP/HDPE/LDPE PE Film Jumbo Woven Bags Plastic Crusher Machine, Plastic Crushing Washing Recycling Machine

-

Type 2 Wall-Mounted Electric Car Charging Station 7kw /11 Kwelectric Vehicle Charging Station Home Wallbox AC EV Charger Single Phase or 3three Phase

Type 2 Wall-Mounted Electric Car Charging Station 7kw /11 Kwelectric Vehicle Charging Station Home Wallbox AC EV Charger Single Phase or 3three Phase

-

G-View G12W Wholesale Auto Car LED Headlight Bulb High Power H13 H11 9005 H7 H4 Car LED Headlights LED Car Lights

G-View G12W Wholesale Auto Car LED Headlight Bulb High Power H13 H11 9005 H7 H4 Car LED Headlights LED Car Lights

-

New Design Porcelain Round Plates Dinner Set for Wedding and Banquet

New Design Porcelain Round Plates Dinner Set for Wedding and Banquet

-

China 2023 New Design Super Soft 100% Polyester Microfiber Knitted Oversized Decoration Hoodie Blanket

China 2023 New Design Super Soft 100% Polyester Microfiber Knitted Oversized Decoration Hoodie Blanket

-

Handmade Art Creative Materials Thickened White Paper Cup DIY Disposable Handmade Colored Paper Cup

Handmade Art Creative Materials Thickened White Paper Cup DIY Disposable Handmade Colored Paper Cup