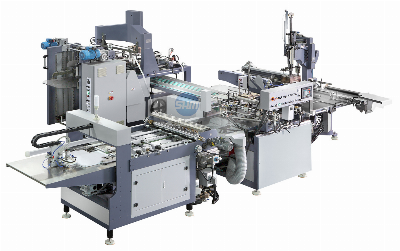

MAIN FEATURES: 1. The feeder in this machine adopts

back-push feeding system, which is controlled pneumatically, and

its structure is simple and reasonable.2. The width between stacker

and feeding table is adjusted concentrically in the center. The

operation is very easy without tolerance.3. New designed copper

scraper cooperates with the roller more compactly, effectively

avoiding paper winding. And the copper scraper is more durable.4.

Adopt imported ultrasonic double paper tester, featuring in simple

operation, which can keep two pieces paper from entering into the

machine at the same time.5. Automatic circulation, mixing and

gluing system for hot-melting glue. (Optional device: glue

viscosity meter)6. Hot-melting paper tape automatic conveying,

cutting, and finish pasting the inner box quad stayer (four angles)

of cardboard in one process. 7. The vacuum suction fan under the

conveyer belt can keep the paper from deviating. 8. The paper and

cardboard inner box employs hydraulic rectifying device to spot

correctly.9. Conveyor belt employs automatic clean system, which

makes belt maintenance easy.10. The wrapper can continually wrap,

fold ears and paper sides and form in one process. 11. The whole

machine employs PLC, photoelectric tracking system and HMI to

automatically forming boxes in one process. 12. It can

automatically diagnose the troubles and alarm accordingly.

MAIN SPECIFICATIONS: Paper

sizeMax.580x800mmMin.100x200mmPaper thickness100-200g/m2Cardboard

thickness1-3mmFinished product (box)

sizeMax.420x300x70mmMin.100x50x10mmFolded paper

size10-35mmPrecision±0.5mmProduction

speedMax.35sheets/minPower10kw 380V 3phaseHeater

power7.8kwAir

Supply10L/min 0.6MpaWeight4500kgDimension7200x4100x2800mm

Our serviceAt SHM , you can expect satisfactory customer

service with long tradition. We are highly devoted to the most

optimal solid and liquid separation solutions to meet your specific

needs. We have the effective service system to ensure professional

and flexible management of any affairs.1.Pre-sales technical

consultation2.Model selection3.Machine guidance4.Operation &

maintenance training5.Maintenance service6.Quick supply of spare

parts7.Customer satisfaction trackAfter-sale ServiceSHM

promises that all machines made by us come with services of repair

and replacement. Machine warranty is 12 months. We provide free

repair services to any failures caused by us within warranty time.

However wearing parts are not included.1.Any quality failure

problems happens within guarantee period, we will reply within 4

hours after receiving your request.2.SHM will provide lifelong

maintenance service to all parts and regular maintenance to flatbed

die cutters.3.We will handle any quality failure occurred within

warranty time.4.We will provide lifelong technical support started

from using of the machine.5.We will supply normal parts within

warranty period to ensure better user experience. Parts supply will

be charged after warranty

period.FAQQ : What about the price of the machine?

A:Pls contact with our sales manager to get quotation or pls send mail to us to get more information.

Q:How long is the warranty of the machines ?And other Service ?

A: Warranty is 12 months after the machines arrive.

Our engineer can provide service overseas if you need.

And we also provide installation and operation training.

Q : How about your delivery time ?

A:The delivery time is within 30-60 days depend on the different type or machine. Pls contact with us to learn more.

Q:What`s the price term and payment method?

A:We usually use Fob, CIF and CFR.

Payment method : 100 % T/T (30% deposit + 70% before shipment ) OR 100% L/C.

/* March 10, 2023 17:59:20 */!function(){function s(e,r){var

a,o={};try{e&&e.split(",").forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

Related products about Rb420 Automatic Case Maker for Hardcover and Rigid Box

-

Waste Tyre Plastic Recycling Machinery Machine Tire Crusher Production Line Rubber Crumb Grinding Machine Equipment Tire Shredder

Waste Tyre Plastic Recycling Machinery Machine Tire Crusher Production Line Rubber Crumb Grinding Machine Equipment Tire Shredder

-

Stretch Plastic Blowing Pet Bottle Making Blow Molding Machine Bottles Stretch Automatic Pet Bottle Blowing Machine

Stretch Plastic Blowing Pet Bottle Making Blow Molding Machine Bottles Stretch Automatic Pet Bottle Blowing Machine

-

Waste Plastic Pet Bottle, Water Bottle Flake, PP/HDPE/LDPE PE Film Jumbo Woven Bags Plastic Crusher Machine, Plastic Crushing Washing Recycling Machine

Waste Plastic Pet Bottle, Water Bottle Flake, PP/HDPE/LDPE PE Film Jumbo Woven Bags Plastic Crusher Machine, Plastic Crushing Washing Recycling Machine

-

Type 2 Wall-Mounted Electric Car Charging Station 7kw /11 Kwelectric Vehicle Charging Station Home Wallbox AC EV Charger Single Phase or 3three Phase

Type 2 Wall-Mounted Electric Car Charging Station 7kw /11 Kwelectric Vehicle Charging Station Home Wallbox AC EV Charger Single Phase or 3three Phase

-

G-View G12W Wholesale Auto Car LED Headlight Bulb High Power H13 H11 9005 H7 H4 Car LED Headlights LED Car Lights

G-View G12W Wholesale Auto Car LED Headlight Bulb High Power H13 H11 9005 H7 H4 Car LED Headlights LED Car Lights

-

New Design Porcelain Round Plates Dinner Set for Wedding and Banquet

New Design Porcelain Round Plates Dinner Set for Wedding and Banquet

-

China 2023 New Design Super Soft 100% Polyester Microfiber Knitted Oversized Decoration Hoodie Blanket

China 2023 New Design Super Soft 100% Polyester Microfiber Knitted Oversized Decoration Hoodie Blanket

-

Handmade Art Creative Materials Thickened White Paper Cup DIY Disposable Handmade Colored Paper Cup

Handmade Art Creative Materials Thickened White Paper Cup DIY Disposable Handmade Colored Paper Cup