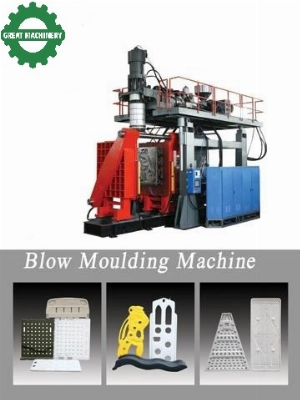

Servo Motor Energy Saving Big container Drum Plastic Extusion Blow

Moulding Machinery Blow Moulding Machinery GRT120-120L(max

produce 120L)is good quality single-station automatic blow molding

machines. It is suitable for producing high quality container with

medium output. It specializes in the manufacture of PEPPPVCTPUPETA

containers of up to 120L. For use in the packaging of petroleum,

cosmetics, chemicals, pharmaceuticals, food, toys and

auto-parts.**Presentation of the basic configuration:1. Extrusion

systemScrew: Specially designed based on material's trait, High

quality nitriding steel 38CrMoAlA, with nitriding surface HV≥ 800,

brittleness≤ 2;Barrel: High quality nitriding steel 38CrMoAlA, with

nitriding surface HV≥ 900, brittleness≤ 2;Drive mode: Inverter +

hard gear surface decelerator;Heating mode: Porcelain

heaters;Temperature controlling: Automatic temperature control

model;Mode of cooling: Automatic fan cooler.2. Die head

systemCentral incoming die head, totally eliminating the converging

line of products, the surface is colorful and uniform; This die

head is able to be used to match polyethylene, polypropylene and so

on;Heating mode: Stainless steel heaterTemperature controlling:

Temperature controlling model;Clamping systemDouble bar horizontal

motion structure in moving, opening and closing mold, making the

clamping force equally distributed, so the cut is smoother.Redesign

in accordance with the molding requirement of the sample for

efficient productivity.Frame: It's able to move up and down.3.

Hydraulic systemAdopted proportional pressure controlling, with

hydraulic valve of Japan Yuken and pump of Taiwan Sensor, balanced

and accurate action, prolonged useful life, sensitive response.4.

Electric controlling systemProgram controlling with Japan

Mitsubishi PLC; Complete machine communication, parameter setting /

modification and menu displaying with the Taiwan Hitech liquid

crystal display and touch screen; Every parameter could be set and

modified directly with the complete obstacle self-diagnosing

function, menu operated directly and conveniently.Extrusion motor

with the inverter controlling and alloy hard gear surface

decelerator driving, saving power, lower noise, balanced and stable

screw rotation.Safety configuration: Safety door, safety switch

protectionProduct Parameters Main

ParametersUnitGRT120-120LMax. Product Volume(L)120Dry

Cycle(pcs/h)360Screw Diameter(mm)100Screw L/D Ratio(L/D)28Screw

Drive Power(KW)55Screw heating Power(4ΦKW)24Screw Heating

Zone(Zone)4HPDE Output(kg/h)200Oil Pump Power(KW)37Clamping

Force(KN)650Mold Stroke(mm)550-1400Max. Mold

Size(W×H)(mm)800×1250Accumulator Capacity(L)14Max. Die

Diameter(mm)450Die Heating Power(4ΦKW)21NO. of Heating

Zone(Zone)5Blowing Pressure(MPa)0.8Air Consumption(M 3

/min)1.6Cooling Water Pressure(MPa)0.3Water

Consumption(L/min)150Machine Size(L×W×H)(m)5.4×2.6×4.2Machine

Weight(Ton)19Component PartsDie system--------Central-incoming

extrusion die with special steelHydraulic system--Japan hydraulic

valve seal and proportional controlControl system---- Import

PLC+Human-machine+PLC automatic temperature control

model Sample photoFAQ /* March 10, 2023 17:59:20

*/!function(){function s(e,r){var

a,o={};try{e&&e.split(",").forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

Related products about Servo Motor Energy Saving Big Container Drum Plastic Extusion Blow Moulding Machinery

-

Waste Tyre Plastic Recycling Machinery Machine Tire Crusher Production Line Rubber Crumb Grinding Machine Equipment Tire Shredder

Waste Tyre Plastic Recycling Machinery Machine Tire Crusher Production Line Rubber Crumb Grinding Machine Equipment Tire Shredder

-

Stretch Plastic Blowing Pet Bottle Making Blow Molding Machine Bottles Stretch Automatic Pet Bottle Blowing Machine

Stretch Plastic Blowing Pet Bottle Making Blow Molding Machine Bottles Stretch Automatic Pet Bottle Blowing Machine

-

Waste Plastic Pet Bottle, Water Bottle Flake, PP/HDPE/LDPE PE Film Jumbo Woven Bags Plastic Crusher Machine, Plastic Crushing Washing Recycling Machine

Waste Plastic Pet Bottle, Water Bottle Flake, PP/HDPE/LDPE PE Film Jumbo Woven Bags Plastic Crusher Machine, Plastic Crushing Washing Recycling Machine

-

Type 2 Wall-Mounted Electric Car Charging Station 7kw /11 Kwelectric Vehicle Charging Station Home Wallbox AC EV Charger Single Phase or 3three Phase

Type 2 Wall-Mounted Electric Car Charging Station 7kw /11 Kwelectric Vehicle Charging Station Home Wallbox AC EV Charger Single Phase or 3three Phase

-

G-View G12W Wholesale Auto Car LED Headlight Bulb High Power H13 H11 9005 H7 H4 Car LED Headlights LED Car Lights

G-View G12W Wholesale Auto Car LED Headlight Bulb High Power H13 H11 9005 H7 H4 Car LED Headlights LED Car Lights

-

New Design Porcelain Round Plates Dinner Set for Wedding and Banquet

New Design Porcelain Round Plates Dinner Set for Wedding and Banquet

-

China 2023 New Design Super Soft 100% Polyester Microfiber Knitted Oversized Decoration Hoodie Blanket

China 2023 New Design Super Soft 100% Polyester Microfiber Knitted Oversized Decoration Hoodie Blanket

-

Handmade Art Creative Materials Thickened White Paper Cup DIY Disposable Handmade Colored Paper Cup

Handmade Art Creative Materials Thickened White Paper Cup DIY Disposable Handmade Colored Paper Cup