Company ProfileZhejiang Tieyong Machinery Manufacturing Co., Ltd.

is located in Gaohu Industrial Zone, Gaohu Town, Qingtian County,

Zhejiang Province, China. Foundry company covers an area of 17,000

square meters, building area of 13,000 square meters; Copper

Aluminum Zinc Company covers an area of 20000 square meters. We are

good at making all kinds of mechanical parts. Our production

processes include investment casting (precision casting), coated

sand casting, lost mold casting, calcination, red stamping,

machining (CNC machining), rod machining, injection molding and

stamping. We have 8 wax shooting machines with 13 stations, 2 sets

of shell drying line, 1 set of disappearing mold production line, 1

set of coated sand production line, 1 set of forging line, 6 sets

of medium frequency casting furnace, more than 30 sets of solid

solution after cleaning, investment casting spectral analysis

instruments. More than 30 sets of die-casting red forging, 16 sets

of injection molding machines, 3 sets of high material high-speed

extrusion production lines, 10 sets of punching press, more than

200 sets of finishing equipment. Material range includes stainless

steel, carbon steel, alloy steel, copper alloy, aluminum alloy,

zinc alloy, plastic and so on. There are 10 technical engineers, 4

inspection engineers, 2 production engineers, 42 technical

production masters of each specialty, and more than 400 other

operating personnel. Our company is export-oriented, selling to

Australia, USA, Canada, UK, (UK, UK), Netherlands, France, Germany,

Denmark, Sweden, Finland, Russia, Spain, Portugal. The products are

widely used in heavy equipment, automotive spare parts, Marine

parts, petrochemical processing, wind turbine equipment, power

plant, substation accessories, food processing industry and medical

instruments. We do non-standard customized mechanical parts, can be

produced according to the demand. "Integrity-based, quality first,

service first" is our business philosophy, unity and enterprising,

better, faster, stronger is our most sought goal, we are committed

to build a talent team, integrate industry resources, and strive to

further develop into a great machine parts manufacturing

enterprise. We look forward to working with you to create a better

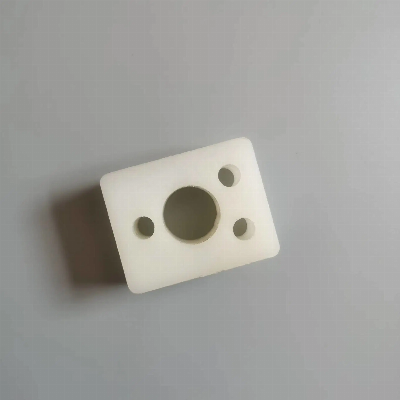

future.Item NameOEM high-precision plastic injection molding

tooling service plastic injection parts Mould Core/Cavity

DIN2312,2738,2344,718,S136,8407,NAK80,SKD61,P20, P20HH, H13, 420ss

etc. Hardness of steel 33-38HRC prehard, 46~56 HRC hardened Mould

Standard HASCO,DME,MEUSBURGER,JIS,CHINA LKM Standard Mould Base

LKM&Hasco&DME standard (A,B plate 1730,2311,2312,1050,P20 )

Cavity Single/Family/Multi Runner Hot/Cold Runner Mould Size

150*150mm Min, 3000*2500mm Max Surface of Mould EDM VDI/ High

Polish&Texture Plastic material PP, PC, PS, PE, PET, POM, PA,

PU, PVC, ABS, HIPS, PMMA, Nylon, and with GF, etc. Mould Life

Prototype 1000-25,000; preproduction 50,000-10,0000; High

production 300,000-1,000,000 shots based on Volume requirements

Specification Depends on the customer's requirements. Trade terms

FOB Shenzhen, EXW, CIF Export to Europe

countries,USA,Mexico,Australia ,Middle-east ,Asia etc Mold hot

runner DME, HASCO, YUDO, Mold-Masters, HRS, Synventive, etc,

or per customer requirement Mold gate type point gate, side gate,

sub gate, tunnel gate, banana gate, direct gate, tab gate, hot

runner valve gate, hot runner to cold runner, etc. Lead time 1st

Trial 20-45Days based on different molds Outside package Standard

wooden cases or as your requirement Inner package Stretch

waterproof film & Each Mold painted, anti-rust oil.3. Spare parts

together with the mold shipment. 4. Vaccum package Product

image Packaging & Shipping FAQ /* March 10, 2023

17:59:20 */!function(){function s(e,r){var

a,o={};try{e&&e.split(",").forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

Related products about Molded Products Components Supplier Home Appliance Manufacture Plastic Injection Molding/Parts/Supplier/Vehicle Parts/Sparepart/Equipment/Enclosure/Truck Parts

-

Waste Tyre Plastic Recycling Machinery Machine Tire Crusher Production Line Rubber Crumb Grinding Machine Equipment Tire Shredder

Waste Tyre Plastic Recycling Machinery Machine Tire Crusher Production Line Rubber Crumb Grinding Machine Equipment Tire Shredder

-

Stretch Plastic Blowing Pet Bottle Making Blow Molding Machine Bottles Stretch Automatic Pet Bottle Blowing Machine

Stretch Plastic Blowing Pet Bottle Making Blow Molding Machine Bottles Stretch Automatic Pet Bottle Blowing Machine

-

Waste Plastic Pet Bottle, Water Bottle Flake, PP/HDPE/LDPE PE Film Jumbo Woven Bags Plastic Crusher Machine, Plastic Crushing Washing Recycling Machine

Waste Plastic Pet Bottle, Water Bottle Flake, PP/HDPE/LDPE PE Film Jumbo Woven Bags Plastic Crusher Machine, Plastic Crushing Washing Recycling Machine

-

Type 2 Wall-Mounted Electric Car Charging Station 7kw /11 Kwelectric Vehicle Charging Station Home Wallbox AC EV Charger Single Phase or 3three Phase

Type 2 Wall-Mounted Electric Car Charging Station 7kw /11 Kwelectric Vehicle Charging Station Home Wallbox AC EV Charger Single Phase or 3three Phase

-

G-View G12W Wholesale Auto Car LED Headlight Bulb High Power H13 H11 9005 H7 H4 Car LED Headlights LED Car Lights

G-View G12W Wholesale Auto Car LED Headlight Bulb High Power H13 H11 9005 H7 H4 Car LED Headlights LED Car Lights

-

New Design Porcelain Round Plates Dinner Set for Wedding and Banquet

New Design Porcelain Round Plates Dinner Set for Wedding and Banquet

-

China 2023 New Design Super Soft 100% Polyester Microfiber Knitted Oversized Decoration Hoodie Blanket

China 2023 New Design Super Soft 100% Polyester Microfiber Knitted Oversized Decoration Hoodie Blanket

-

Handmade Art Creative Materials Thickened White Paper Cup DIY Disposable Handmade Colored Paper Cup

Handmade Art Creative Materials Thickened White Paper Cup DIY Disposable Handmade Colored Paper Cup