1. No elastic sliding and skidding, can maintain accurate average

transmission ratio, high transmission efficiency (closed chain

transmission efficiency n =0. 95~0.98); The chain does not need to

be as tight as the belt, so the compression force is less; High

transmission power, strong overload capacity; Can work well under

low speed and heavy load; Can adapt to harsh environment such as

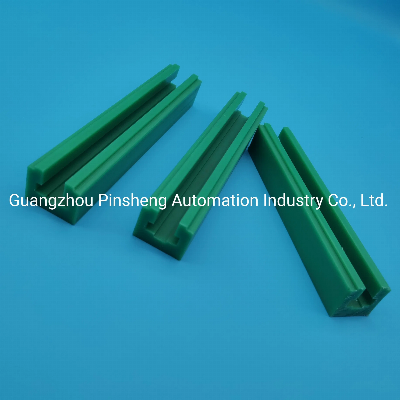

dust, oil, corrosion and high strength occasions. 2. Slider changes

the activity from a curve to a straight line. The new guide rail

system enables the machine to obtain fast feed speed, fast feed is

the characteristic of the chain guide rail under the condition of

the same spindle speed. 3, chain guide and plane guide, there are

two basic components; One is a fixed element as a guide and the

other is a moving element. Because chain guides are standard parts

for machine tool manufacturers. The only thing to do is to process

a plane to mount the guide rail and adjust the parallelism of the

guide rail. 4. The guide rail as a guide is hardened steel, which

is placed on the installation plane after fine grinding. Compared

with the plane guide, the cross-section geometry of the chain guide

is more complex than the plane guide. 5. There is no central medium

between the moving components and the fixed components of the chain

guide rail, and the rolling steel ball is used. Because the rolling

steel ball is suitable for high speed movement, small friction

coefficient, high sensitivity, satisfied with the working

requirements of moving parts, such as the tool carrier of machine

tools, dragging plates, etc. 6.The chain guide is used to support

and guide the chain. Reduce chain friction. Reduce noise. Increase

the service life of the chain. It is used in almost every industry

for driving-chain, belt or chain drives or product transmissions /*

March 10, 2023 17:59:20 */!function(){function s(e,r){var

a,o={};try{e&&e.split(",").forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

Related products about Ultra-High Molecular Weight Polyethylene Chain Guide Rail

-

Waste Tyre Plastic Recycling Machinery Machine Tire Crusher Production Line Rubber Crumb Grinding Machine Equipment Tire Shredder

Waste Tyre Plastic Recycling Machinery Machine Tire Crusher Production Line Rubber Crumb Grinding Machine Equipment Tire Shredder

-

Stretch Plastic Blowing Pet Bottle Making Blow Molding Machine Bottles Stretch Automatic Pet Bottle Blowing Machine

Stretch Plastic Blowing Pet Bottle Making Blow Molding Machine Bottles Stretch Automatic Pet Bottle Blowing Machine

-

Waste Plastic Pet Bottle, Water Bottle Flake, PP/HDPE/LDPE PE Film Jumbo Woven Bags Plastic Crusher Machine, Plastic Crushing Washing Recycling Machine

Waste Plastic Pet Bottle, Water Bottle Flake, PP/HDPE/LDPE PE Film Jumbo Woven Bags Plastic Crusher Machine, Plastic Crushing Washing Recycling Machine

-

Type 2 Wall-Mounted Electric Car Charging Station 7kw /11 Kwelectric Vehicle Charging Station Home Wallbox AC EV Charger Single Phase or 3three Phase

Type 2 Wall-Mounted Electric Car Charging Station 7kw /11 Kwelectric Vehicle Charging Station Home Wallbox AC EV Charger Single Phase or 3three Phase

-

G-View G12W Wholesale Auto Car LED Headlight Bulb High Power H13 H11 9005 H7 H4 Car LED Headlights LED Car Lights

G-View G12W Wholesale Auto Car LED Headlight Bulb High Power H13 H11 9005 H7 H4 Car LED Headlights LED Car Lights

-

New Design Porcelain Round Plates Dinner Set for Wedding and Banquet

New Design Porcelain Round Plates Dinner Set for Wedding and Banquet

-

China 2023 New Design Super Soft 100% Polyester Microfiber Knitted Oversized Decoration Hoodie Blanket

China 2023 New Design Super Soft 100% Polyester Microfiber Knitted Oversized Decoration Hoodie Blanket

-

Handmade Art Creative Materials Thickened White Paper Cup DIY Disposable Handmade Colored Paper Cup

Handmade Art Creative Materials Thickened White Paper Cup DIY Disposable Handmade Colored Paper Cup