Product DescriptionFeatures1. The full-stroke follow-up pneumatic

chuck has a proper degree of clamping, and the thin plate is not

deformed. The pneumatic chuck can automatically center and clamp

the work piece instantly by pressing a button, and the clamping

force is stable and adjustable. It is beneficial to improve

production efficiency. The structure of the pneumatic chuck is

simple, the use cost and failure rate are low, and it is

environmentally friendly and pollution-free. It mainly uses air as

the power source. The pneumatic chuck adopts a fully enclosed

structure, and the parts are carefully selected. With dust-proof

function, combined with unique material selection and heat

treatment process, it greatly exceeds the service life of the

manual chuck. The pneumatic chuck generates force through the

conversion of air pressure and the angle of the wedge. In addition

to the large clamping force, it also has super self-locking.

Function, in the case of disconnecting the air source, the work

piece can still be firmly clamped for cutting, which completely

solves the safety and reliability aspects for customers. 2.

The transmission system adopts internationally renowned brands,

with stable transmission, fast speed and high positioning accuracy.

It has stable operation, low noise, shock absorption and buffering,

compact center distance and small shape, constant transmission

ratio, wide selection of peripheral speed and power, accurate

transmission, high efficiency, compact structure, reliable

operation and long life. The instantaneous transmission ratio is

constant, and the transmission ratio range is large, which can be

used for deceleration or acceleration. The range of speed

(circumferential speed of the knuckle circle) and transmission

power is large, which can be used for high-speed, medium-speed and

low-speed transmission; the power applicability range is wide, the

transmission efficiency is high, and it is suitable for

short-distance transmission. 3. The integrated power

distribution cabinet design has the following advantages:1) The

failure rate is low. Since the failure rate of integrated circuits

is relatively low compared to discrete component circuits, the

failure rate of the whole machine circuit is reduced.2) The circuit

is simple. Due to the use of integrated circuits, the design,

debugging and installation of the whole machine circuit are

simplified, especially after some special integrated circuits are

used, the whole machine circuit is simpler.3) The energy

consumption is small, and the integrated circuit also has the

advantages of small power consumption, small size and economy.4)

High cost performance. Compared with discrete component circuits,

the performance indicators of the whole circuit composed of

integrated circuits are higher. Compared with discrete electronic

component circuits, the cost and price of integrated circuits are

lower.5) Strong reliability, the integrated circuit has the

advantages of high reliability, thereby improving the reliability

of the circuit operation of the whole machine, and improving the

working performance and consistency of the circuit. Product

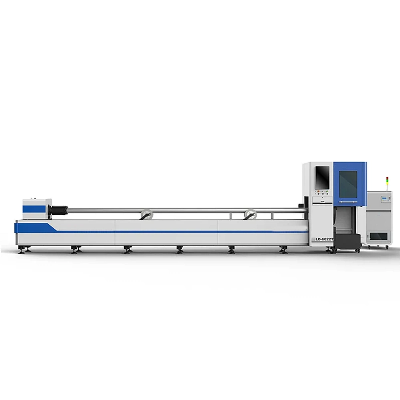

ParametersLD6022T Tube Laser Cutting

MachineModelLD6012TLD6022TChuck holding diameter15-120mm15-220mmMax

processing le ngth6000mmPositioning

accuracy±0.03mm/mRepeated positioning

accuracy±0.02mm/mMax acceleration1.0GMax positioning

speed80m/minLaser power1KW-3KWOther dimensions can be

customized Detailed PhotosChuck clamping diameter:

15-110/220mm, supports high-speed and high-quality cutting of

stainless steel pipes such as square pipes, round pipes, I-beams,

channel steels, angle steels, and carbon steel pipes.Front and rear

double pneumatic chucks, full stroke self-centering, high

positioning accuracy, one-button clamping, adjustable clamping

force, stable and efficient.The bed structure is optimized and

upgraded, after high-temperature annealing heat treatment,

vibration aging and other precision processing, the welding stress

and processing stress are effectively eliminated, the product

accuracy is guaranteed, and the bed is more reliableThe anti-shake

and stable support can prevent the large deflection of the pipe and

improve the cutting precision. Sample DisplayProduction

Process/* March 10, 2023 17:59:20 */!function(){function s(e,r){var

a,o={};try{e&&e.split(",").forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

Related products about Ld6022t Tube Laser Cutting Machine

-

Waste Tyre Plastic Recycling Machinery Machine Tire Crusher Production Line Rubber Crumb Grinding Machine Equipment Tire Shredder

Waste Tyre Plastic Recycling Machinery Machine Tire Crusher Production Line Rubber Crumb Grinding Machine Equipment Tire Shredder

-

Stretch Plastic Blowing Pet Bottle Making Blow Molding Machine Bottles Stretch Automatic Pet Bottle Blowing Machine

Stretch Plastic Blowing Pet Bottle Making Blow Molding Machine Bottles Stretch Automatic Pet Bottle Blowing Machine

-

Waste Plastic Pet Bottle, Water Bottle Flake, PP/HDPE/LDPE PE Film Jumbo Woven Bags Plastic Crusher Machine, Plastic Crushing Washing Recycling Machine

Waste Plastic Pet Bottle, Water Bottle Flake, PP/HDPE/LDPE PE Film Jumbo Woven Bags Plastic Crusher Machine, Plastic Crushing Washing Recycling Machine

-

Type 2 Wall-Mounted Electric Car Charging Station 7kw /11 Kwelectric Vehicle Charging Station Home Wallbox AC EV Charger Single Phase or 3three Phase

Type 2 Wall-Mounted Electric Car Charging Station 7kw /11 Kwelectric Vehicle Charging Station Home Wallbox AC EV Charger Single Phase or 3three Phase

-

G-View G12W Wholesale Auto Car LED Headlight Bulb High Power H13 H11 9005 H7 H4 Car LED Headlights LED Car Lights

G-View G12W Wholesale Auto Car LED Headlight Bulb High Power H13 H11 9005 H7 H4 Car LED Headlights LED Car Lights

-

New Design Porcelain Round Plates Dinner Set for Wedding and Banquet

New Design Porcelain Round Plates Dinner Set for Wedding and Banquet

-

China 2023 New Design Super Soft 100% Polyester Microfiber Knitted Oversized Decoration Hoodie Blanket

China 2023 New Design Super Soft 100% Polyester Microfiber Knitted Oversized Decoration Hoodie Blanket

-

Handmade Art Creative Materials Thickened White Paper Cup DIY Disposable Handmade Colored Paper Cup

Handmade Art Creative Materials Thickened White Paper Cup DIY Disposable Handmade Colored Paper Cup