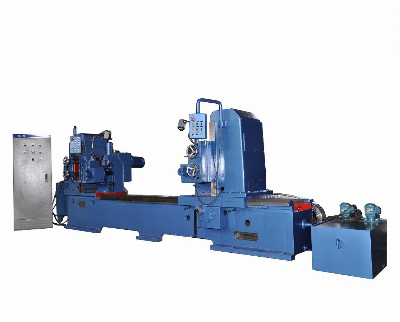

roller conveyor 2 ends shaft milling machine 2700mm length high

precisionparameter: specificationXZ36-6×230XZ36-6×270Speed

for spindle500,700,900r/min500,700,900r/minDiameter of roller shaft

processedΦ18~Φ60mm Φ18~Φ60mm Length of roller shaft

processed200~2300mm 200~2700mm Processing shaft groove

width6~45mm 6~45mm Cutting

depth 0~5mm 0~5mm Spindle

motor3kW×2(SET) 3kW×2(SET) Oil pump

motor 5.5kW 5.5kW Hydraulic system Working

pressure1.5~4MPa 1.5~4MPa Hydraulic System

Flow31L/min31L/minCooling bump motor125W×2125W×2Equipment

size4050mm×1300mm×1600mm4450mm×1300mm×1600mm main performanceA.it's a automatic machine to produce the oblate slot of the both sides

through clamping the roller carrier shaft which used in the conveyor roller.B.There are four spindle boxes in the machine,and each spindle

box spindle box spinning processing with one milling cutter.C.Suitable environment temperature:0-40ºCD.No corrosive medium and dust occasionMain

performance and application This machine is an automatic

equipment which could process the two ends of the belt conveyor

roller shaft by a single clamping, which could meet the

requirements of the processing of roller shaft produced both at

domestic or abroad.Because every roller shaft has four grooves, the

machine has four spindle boxes, a milling cutter is drove by a

spindle box to process a groove.Workpieces are clamped pm the

V-shaped iron by hydraulic. Droved by hydraulic, the four spindle

boxes move up and down when processing, to realize fast forward,

work into (cutting) and fast backward. The electronic control

system applied imported programmable controller (PLC) as the center

for process control, which with high degree of automation, high

efficiency and reliability. It's suitable for volume production of

roller shaft. /* March 10, 2023 17:59:20

*/!function(){function s(e,r){var

a,o={};try{e&&e.split(",").forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

Related products about Roller Conveyor 2 Ends Shaft Milling Machine 2700mm Length High Precision

-

Waste Tyre Plastic Recycling Machinery Machine Tire Crusher Production Line Rubber Crumb Grinding Machine Equipment Tire Shredder

Waste Tyre Plastic Recycling Machinery Machine Tire Crusher Production Line Rubber Crumb Grinding Machine Equipment Tire Shredder

-

Stretch Plastic Blowing Pet Bottle Making Blow Molding Machine Bottles Stretch Automatic Pet Bottle Blowing Machine

Stretch Plastic Blowing Pet Bottle Making Blow Molding Machine Bottles Stretch Automatic Pet Bottle Blowing Machine

-

Waste Plastic Pet Bottle, Water Bottle Flake, PP/HDPE/LDPE PE Film Jumbo Woven Bags Plastic Crusher Machine, Plastic Crushing Washing Recycling Machine

Waste Plastic Pet Bottle, Water Bottle Flake, PP/HDPE/LDPE PE Film Jumbo Woven Bags Plastic Crusher Machine, Plastic Crushing Washing Recycling Machine

-

Type 2 Wall-Mounted Electric Car Charging Station 7kw /11 Kwelectric Vehicle Charging Station Home Wallbox AC EV Charger Single Phase or 3three Phase

Type 2 Wall-Mounted Electric Car Charging Station 7kw /11 Kwelectric Vehicle Charging Station Home Wallbox AC EV Charger Single Phase or 3three Phase

-

G-View G12W Wholesale Auto Car LED Headlight Bulb High Power H13 H11 9005 H7 H4 Car LED Headlights LED Car Lights

G-View G12W Wholesale Auto Car LED Headlight Bulb High Power H13 H11 9005 H7 H4 Car LED Headlights LED Car Lights

-

New Design Porcelain Round Plates Dinner Set for Wedding and Banquet

New Design Porcelain Round Plates Dinner Set for Wedding and Banquet

-

China 2023 New Design Super Soft 100% Polyester Microfiber Knitted Oversized Decoration Hoodie Blanket

China 2023 New Design Super Soft 100% Polyester Microfiber Knitted Oversized Decoration Hoodie Blanket

-

Handmade Art Creative Materials Thickened White Paper Cup DIY Disposable Handmade Colored Paper Cup

Handmade Art Creative Materials Thickened White Paper Cup DIY Disposable Handmade Colored Paper Cup