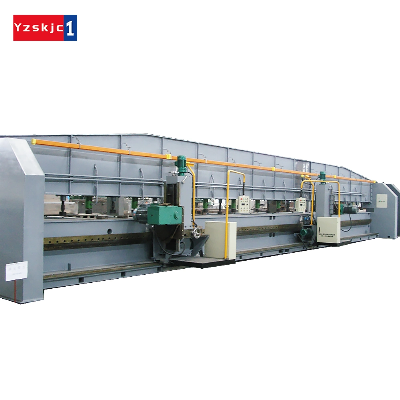

BBJ planing machine tool is my company CNC machine automation

engineering research institute and Shanghai Jiaotong University

jointly introduced and absorbed special machine tool technology at

home and abroad, has accumulated more than 20 years of machine tool

production experience and has independent intellectual property

rights of CNC machine tool series products. Feature one: the

product replaces the old planing machine tool using worm gear

transmission mode leading to the horizontal feed and vertical feed

due to the bevel gear cutting impact force caused by the horizontal

feed axial force load large, failure, damage can not automatically

feed, so the cutting process in the failure rate is higher,

difficult to operate, low efficiency, easy cutting tool

shortcomings. After improvement, the tool is added and the coolant

device is used in high power cutting to prevent the phenomenon of

burning the tool. Feature 2: This machine realizes the man-machine

combination, automatic function and manual function coexist design

concept, truly realizes man-machine combination, convenient for the

operator to operate in any state. At the same time, the groove

forms of various metal materials, such as: double X, V, U, O groove

can be processed. Feature 3: After introducing and improving the

wear-resisting technology of German machine tool guide, our company

composite SF wear-resisting and high temperature resistant material

on the contact adjusting plate with guide rail. 1. Headstock

Machine tool spindle all adopt resin sand modeling of high strength

casting iron parts, with strong rigidity, convenient speed control,

no block, the use of mechanical and electrical integration

technology, frequency control, reduce the strength and skills of

the simple operator, to achieve man-machine combination and other

functions. Ii. Machine tool structure and guide rail: Machine

structure using HT250 resin sand molding structure of cast iron or

welded steel structure, the selection of steel plate welding, the

body of the whole annealing, stress elimination, the bed after

rough machining, secondary aging vibration, and then finishing. The

guide rail is made of steel parts. After surface quenching, the

guide rail is grinded as a whole to meet the precision requirements

of the machine tool. Iii. Upper frame and oil pump system: The

upper pressure device, using the current design and manufacturing

process, the selection of arc structure, stress diffusion, install

the cylinder and mechanical clamping device, automatic and manual

functions to improve the reliability and safety of the equipment,

drive screw conditioning treatment, enhance the strength and

rigidity of the screw. Four, electrical control Mechanical and

electrical integration design concept, all equipped with automatic,

manual horizontal and vertical feed, alarm and other functions,

automatic and manual function, to achieve man-machine combination,

so as to facilitate operation, some electrical appliances using

Schneider, Panasonic, Mitsubishi and so on. Note: Technical

parameters can be changed according to customer requirements. BBJ

planing machine tool is a series of CNC machine tools introduced

and absorbed by the CNC Machine Tool Automation Engineering

Research Institute of our company, accumulated more than 20 years

of machine tool production experience and has independent

intellectual property rights. Feature 1: the horizontal feed and

vertical feed of the tool holder of the planing machine, the use of

servo motor to drive the screw nut transmission, replacing the old

planing machinetoolusing worm gear transmission mode, resulting in

horizontal feeding and vertical feeding due to the large impact of

the cutting force of the bevel gear, resulting in large axial load,

failure, damage can not be automatically fed, resulting in high

failure rate in the cutting process, difficult to operate, Low

efficiency, easy to plant knives and other disadvantages.

Ourcompany's planervertical feed and horizontalfeed are equipped

with manual feed, which is convenient for manual operation during

electrical maintenance of the machine. Feature 2: This product

adopts the design concept of advanced programmablePLCautomatic

control systemand manual function, which truly realizes the

combination of man-machine, has fast command execution speed,

efficient motion control, and strong real-time performance. At the

same time, the groove form of various metal materials, such as: Y,

U, V,X-shaped and other groovescan be processed. Feature three:

Especially after our company introduced the wear-resistant

technology of German machine tool guide rail and improved it, our

company adopts SF wear-resistant and high-temperature resistant

materials, and is compounded on the adjustment pad in contact with

the guide rail. After hundreds of thousands of tests, there is no

hair pulling phenomenon after long-term use. Our company is a

national high-tech enterprise, an innovative enterprise in Jiangsu

Province, and a

Related products about Edge Planer Machine

-

Waste Tyre Plastic Recycling Machinery Machine Tire Crusher Production Line Rubber Crumb Grinding Machine Equipment Tire Shredder

Waste Tyre Plastic Recycling Machinery Machine Tire Crusher Production Line Rubber Crumb Grinding Machine Equipment Tire Shredder

-

Stretch Plastic Blowing Pet Bottle Making Blow Molding Machine Bottles Stretch Automatic Pet Bottle Blowing Machine

Stretch Plastic Blowing Pet Bottle Making Blow Molding Machine Bottles Stretch Automatic Pet Bottle Blowing Machine

-

Waste Plastic Pet Bottle, Water Bottle Flake, PP/HDPE/LDPE PE Film Jumbo Woven Bags Plastic Crusher Machine, Plastic Crushing Washing Recycling Machine

Waste Plastic Pet Bottle, Water Bottle Flake, PP/HDPE/LDPE PE Film Jumbo Woven Bags Plastic Crusher Machine, Plastic Crushing Washing Recycling Machine

-

Type 2 Wall-Mounted Electric Car Charging Station 7kw /11 Kwelectric Vehicle Charging Station Home Wallbox AC EV Charger Single Phase or 3three Phase

Type 2 Wall-Mounted Electric Car Charging Station 7kw /11 Kwelectric Vehicle Charging Station Home Wallbox AC EV Charger Single Phase or 3three Phase

-

G-View G12W Wholesale Auto Car LED Headlight Bulb High Power H13 H11 9005 H7 H4 Car LED Headlights LED Car Lights

G-View G12W Wholesale Auto Car LED Headlight Bulb High Power H13 H11 9005 H7 H4 Car LED Headlights LED Car Lights

-

New Design Porcelain Round Plates Dinner Set for Wedding and Banquet

New Design Porcelain Round Plates Dinner Set for Wedding and Banquet

-

China 2023 New Design Super Soft 100% Polyester Microfiber Knitted Oversized Decoration Hoodie Blanket

China 2023 New Design Super Soft 100% Polyester Microfiber Knitted Oversized Decoration Hoodie Blanket

-

Handmade Art Creative Materials Thickened White Paper Cup DIY Disposable Handmade Colored Paper Cup

Handmade Art Creative Materials Thickened White Paper Cup DIY Disposable Handmade Colored Paper Cup