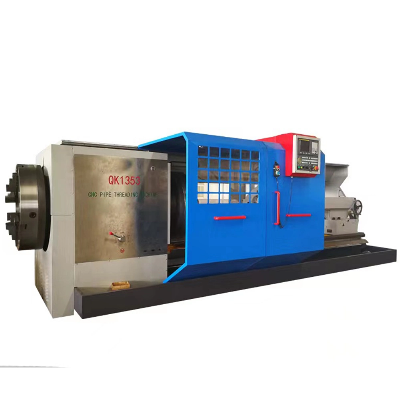

JOINT QK1353 CNC Pipe Thread Lathe Tapping LatheFeatures:1. Big

spindle bore, dual-chuck workpiece is stably clamped.2.

High-quality and high-strength cast iron casting, the overall bed

has good rigidity and high precision.3. The surface of the guide

rail is ultrasonically quenched, with high strength and long

service life. 4. The carriage adopts the guide rail surface pasting

process, which has good wear resistance and high precision.

Specification Sheet: ModelQK1353Nc

System standard equipment:GSK980TDIAlternative configuration:

FANUC oi TF; SIMENS 808D; KND K1000Ti;SIMENS 828DMax dia. swing

over bedmm1250Max dia. swing over cross slidemm860Max. length of

work-piecemm1500Width of bedmm755Spindle boremm540Power of spindle

motorkw22Mode of spindle speed Two gears/smooth

adjustmentRange of spindle speedr/minL:23-120H:65-258Max.traverse

of X/ZmmX:570Z:1250X/Z rapid traversemm/min2000X axis

motorSpeedr/min2000TorgueN.M22Powerkw2.8Z axis

motorSpeedr/min2000TorgueN.m30Powerkw3.5Tailstock

quilDiametermm160Travelmm300Taper Morse

NO.6TurretModel 170A04NTool post type Vertical

four-stationDimensionmm300*300Turret indexing

times5.6Chuck Four jaw electric chuckPositioning

accuracymm0.04Repositioning

accuracymm0.02Dimensionmm5000*2800*2200Weightt18Standard

accessories:1. Taiwan parts step speed milling head2. Working

light3. Draw bar4. Maual oil pump5. Manual operation6. Guide way

cover7. Tool and tool boxOptional accessories:

Water pump

6" Vise

Two axis DRO

Z axis elevator motor

Power feed

Mechanical feed

R8 milling chuck (7pcs)

Clamping kits

NT30/NT40

milling chuck (7 pcs)Package: Company Profile:

Shenzhen Joint Technology Co., Ltd. specializes in

R&D and manufacturing mold processing and machinery parts

processing equipment, we developed high quality and high-tech

research, development, manufacturing, service team

and management system, and expanded products to more than 11

series from milling machines, to machine center,mechanical

arm, automation. With the exceptional quality products and

distinct brand reputation, our products are sold to more than

40 developed cities all over China, and also to more than

20 countries all over the world across Asia, Europe and

America.Our company takes the high quality product as

orientation, R&D ideas is to provide customers with the

most suitable quality products, became a professional machine

tool manufacturer with a complete product line of mould and

parts processing machine tool and strong tailor-made design

capability in China.Special advantages:1. Provide more practical

customized products2. Provide CNC product applications support3.

Provide integrated solution for auto production line4. Provide

integrated design of mold, and parts processing production

lineQualifications and honors:1. National High-tech Enterprose2.

Shenzhen famous brand "JOINT"3. Member of China Quality

Association4. Member of China Machine Tools Association5.

Vice-chairmen of Shenzhen Machinery Association6. CE certification

on milling machine, grinidng machine and machine center.7. More

than 150 patents on invention, utility model patent and software

copyright etc.8. Guangdong famous trademarkFAQ:Q1: Are you trading

company or manufacturer?A1: We are factory.Q2: What is your terms

of payments?A2: 30% as deposit, 70% should be paid before

delivery.Q3: How can I choose the most suitable machines?A3: Please

tell us your requirements of the machines, or you could send us the

products drawing, our engineer can help to choose suitable model

for you.Q4: What is the package? Is it suitable for shipment?A4:

Machine will be packed by exporting standard package, water proof

and anti-rust. It is very much strong for oversea

transportation.Q5: How long is the warranty for machines?A5:

Warranty time is 12 months. We will supply the repair parts in this

warranty time. The charge of repair parts will be free due to its

quality problemin this guarantee./* March 10, 2023 17:59:20

*/!function(){function s(e,r){var

a,o={};try{e&&e.split(",").forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

Related products about Joint Qk1353 CNC Pipe Thread Lathe Tapping Lathe

-

Waste Tyre Plastic Recycling Machinery Machine Tire Crusher Production Line Rubber Crumb Grinding Machine Equipment Tire Shredder

Waste Tyre Plastic Recycling Machinery Machine Tire Crusher Production Line Rubber Crumb Grinding Machine Equipment Tire Shredder

-

Stretch Plastic Blowing Pet Bottle Making Blow Molding Machine Bottles Stretch Automatic Pet Bottle Blowing Machine

Stretch Plastic Blowing Pet Bottle Making Blow Molding Machine Bottles Stretch Automatic Pet Bottle Blowing Machine

-

Waste Plastic Pet Bottle, Water Bottle Flake, PP/HDPE/LDPE PE Film Jumbo Woven Bags Plastic Crusher Machine, Plastic Crushing Washing Recycling Machine

Waste Plastic Pet Bottle, Water Bottle Flake, PP/HDPE/LDPE PE Film Jumbo Woven Bags Plastic Crusher Machine, Plastic Crushing Washing Recycling Machine

-

Type 2 Wall-Mounted Electric Car Charging Station 7kw /11 Kwelectric Vehicle Charging Station Home Wallbox AC EV Charger Single Phase or 3three Phase

Type 2 Wall-Mounted Electric Car Charging Station 7kw /11 Kwelectric Vehicle Charging Station Home Wallbox AC EV Charger Single Phase or 3three Phase

-

G-View G12W Wholesale Auto Car LED Headlight Bulb High Power H13 H11 9005 H7 H4 Car LED Headlights LED Car Lights

G-View G12W Wholesale Auto Car LED Headlight Bulb High Power H13 H11 9005 H7 H4 Car LED Headlights LED Car Lights

-

New Design Porcelain Round Plates Dinner Set for Wedding and Banquet

New Design Porcelain Round Plates Dinner Set for Wedding and Banquet

-

China 2023 New Design Super Soft 100% Polyester Microfiber Knitted Oversized Decoration Hoodie Blanket

China 2023 New Design Super Soft 100% Polyester Microfiber Knitted Oversized Decoration Hoodie Blanket

-

Handmade Art Creative Materials Thickened White Paper Cup DIY Disposable Handmade Colored Paper Cup

Handmade Art Creative Materials Thickened White Paper Cup DIY Disposable Handmade Colored Paper Cup