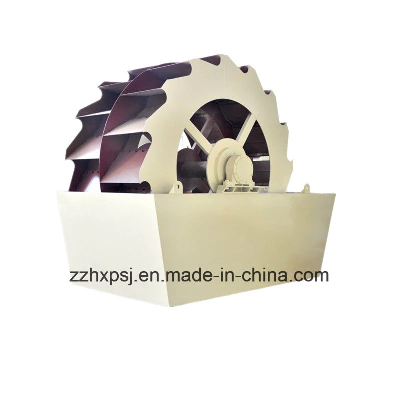

20-50tph Sand Washing Process For Sand Washer

Plant Bucket Wheel Sand Washer Application:Sand

Washing Machine(sand washer) is widely used in particle aggregate

sand screw washing, grading and dehydrating quartz and sand in

construction site, sand stone factories, hydropower station and

concrete dam site, precast concrete factory, glass factory and etc.

It is especially applicable to wash construction sand and paving

sand. This sand washing machine has the features of reliable

structure, convenient maintenance, big capacity, low power

consumption, high cleaning level. The new sealling structure,

totally closed oil bath type drive device and adjustable overflow

weir plate promises that the machine works efficiently.Operating

principle of Sthe bucket wheel sand washer : The electric

motor runs slowly with the impellor after decelerated by the belt,

decelerator and gears wheel. The sand and stone flow into washing

launder from feeding launder, rolls with the impellor, and grinds

each other. The impurity covering the sand is washing away. At the

same time, add more water, the strong water flow will take away

waste and some low-weight wastes from washing launder. Through the

above process, the washing function is finished. The clean sand and

stone is lift up by vane. When it goes up slowly, the water begins

to drop through the mesh and fall back in the washing launder. On

one hand, water is removed from the sand and stone; On the other

hand, the water can be fully used. Finally, the sand and stone goes

to the out launder from the rotary impellor to finish the washing

task. Characteristics of Sand Washing Machine: Reasonable

structure, Large capacity, Low consumption, Little loss of the sand

during the washing process, Low failure rate.Features of bucket

wheel sand washer:1. This machine's structure is simple. The

impeller drive device is seperated with water and the watered

materiel avoiding that the bearing is damaged by deeping in water,

sand, or contamination.2. This machine has obvious advantages

compared with screw sand washer. The details is as follows:3. The

medium and fine sand are washed away less. The washed costruction

sand's gradation and modulus of fineness can get the standard which

is regulated in national ' construction sand' and ' construction

scree and gravel'.4. There is almost no wearing parts except screen

mesh.5. The machine usage life is long.Bucket wheel sand washer

technical parameters: ModelXSD2600XSD2800XSD3000XSD3200Spiral

Diameter( mm)2600280030003200Capacity (t /

h)20-5030-6550-8080-120Motor Power (KW)5.55.57.511Weight (t)

2.6833.43.9Bucket wheel sand washer successfully case :About us

: Zhengzhou Hengxing is a joint stock corporation

integrating scientific research, manufacture, marketing and

exporting with the main target at the large and medium sized series

of heavy duty equipments for mining, ore selecting, wall materials,

formed coal, metallurgy and ect. The company located at Zhengzhou

National High-Tech Development Zone.We are specialized in the

research, development, and production of industrial crushing,

powder grinding, mineral processing equipments and other related

devices. These products include Stone Crushers, Jaw Crushers, Cone

Crushers, Hammer Crushers, and Sand making Machines, Sand Washing

machines, Rod Mills, Powder making Machines, Ore Dressing Machines,

Briquette Machines and complete Cement Output Lines. Our products

have been sold to areas of Southeast Asia, East Europe, South

America, the Middle East and Africa etc, and more foreign markets

will be promoted in future.Our serviceHengxing equipment can

provide turkey service for customers, such as engineering

consultation, engineering design, equipment manufacturing, packing

& transportation, installation & commissioning personnel training

etc.About Spare PartsHengxing equipment will be dedicated to

provide our customers with genuine spare parts with high quality.

With our technological advice, the life cycle of your machine can

be prolonged and sustained significantly with high

effectiveness.About TrainingHengxing equipemnt could offer

excellent facilities and comfortable environment and training

services to different customers. The training should include

product training, safety training, operation training, maintenance

know-how, technical know-how training, and regulations training,

etc. All of the training is customized to fulfill every customer's

expectations. Training programs can be conducted in our workshop,

or at customer's site.About Installation and CommissioningHengxing

equipment are able to guide the overall installation of whole

set production line, including crushing production line and cement

equipment production line, etc., which will allow you to start the

normal operation of equipment immediately. After installation,we

will make inspection of the whole machine commissioning and

operation condition and provide you testing data report of

installation.website: zzhxpsj.en.made-in-china.com C

Related products about 20-50tph Sand Washing Process for Sand Washer Plant

-

Waste Tyre Plastic Recycling Machinery Machine Tire Crusher Production Line Rubber Crumb Grinding Machine Equipment Tire Shredder

Waste Tyre Plastic Recycling Machinery Machine Tire Crusher Production Line Rubber Crumb Grinding Machine Equipment Tire Shredder

-

Stretch Plastic Blowing Pet Bottle Making Blow Molding Machine Bottles Stretch Automatic Pet Bottle Blowing Machine

Stretch Plastic Blowing Pet Bottle Making Blow Molding Machine Bottles Stretch Automatic Pet Bottle Blowing Machine

-

Waste Plastic Pet Bottle, Water Bottle Flake, PP/HDPE/LDPE PE Film Jumbo Woven Bags Plastic Crusher Machine, Plastic Crushing Washing Recycling Machine

Waste Plastic Pet Bottle, Water Bottle Flake, PP/HDPE/LDPE PE Film Jumbo Woven Bags Plastic Crusher Machine, Plastic Crushing Washing Recycling Machine

-

Type 2 Wall-Mounted Electric Car Charging Station 7kw /11 Kwelectric Vehicle Charging Station Home Wallbox AC EV Charger Single Phase or 3three Phase

Type 2 Wall-Mounted Electric Car Charging Station 7kw /11 Kwelectric Vehicle Charging Station Home Wallbox AC EV Charger Single Phase or 3three Phase

-

G-View G12W Wholesale Auto Car LED Headlight Bulb High Power H13 H11 9005 H7 H4 Car LED Headlights LED Car Lights

G-View G12W Wholesale Auto Car LED Headlight Bulb High Power H13 H11 9005 H7 H4 Car LED Headlights LED Car Lights

-

New Design Porcelain Round Plates Dinner Set for Wedding and Banquet

New Design Porcelain Round Plates Dinner Set for Wedding and Banquet

-

China 2023 New Design Super Soft 100% Polyester Microfiber Knitted Oversized Decoration Hoodie Blanket

China 2023 New Design Super Soft 100% Polyester Microfiber Knitted Oversized Decoration Hoodie Blanket

-

Handmade Art Creative Materials Thickened White Paper Cup DIY Disposable Handmade Colored Paper Cup

Handmade Art Creative Materials Thickened White Paper Cup DIY Disposable Handmade Colored Paper Cup