The injection system is equipped with large diameter logic valves

and precise flow control valves,improves injection

response,decreases oil pressure vibration and provides precise

4-stage shot adjustment.Adopts high and low pressure twin pump with

high performance and low noise,saves energy consumption and

improves production efficiency.Adopts automatic concentrated

lubrication system ,directly sets lubrication for times of machine

operation and improves service life of the machine and decrease

repair.The planetary wheel system adopts oil motor to drive the

gear mould adjusting machine structure which is easy to operate

;owns intelligent automatic mould adjusting program ,precisely

calculates the mould locations ,which is convenient for mould

replacing and improves efficiency.The hydraulic main system adopts

double proportional control ,which is convenient for adjusting the

pressure and speed of every movement in the operation .The outlay

precise suction filter ensures the hydraulic system of cleanness

and decreases weariness of the hydraulic components.The hydraulic

ejector is convenient for control with adjustable ejecting

speed. Appliances control:1.Adopts precise artificial

intelligent computer control,can control and supervise the data

and status of every movement,which is convenient for operation

and maintenace.2.The large screen LCD monitor can realize

conversion between Chinese and English.3.Its powerful memory can

store 100 sets of moulding data, such as the

time,times,speed,pressure,traveling distance,mould

thickness,options,etc. 4.Has self-check and alarm functions to

failures of computer hardware,and display function of mechanical

failures,which is convenient for mechanical failure removal

.5.Mould closing adopts high precision E-ruler positioning

test,which can control the precise distance to 0.1mm.Standard

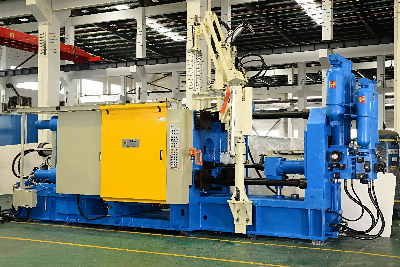

ConfigurationDouble-toggle lock mould structure, high strength

spheroidal graphite iron casting plate.Low pressure mold closing

protection. Mould adjustment device for gear train oil

motor.Concentrated automatic lubrication system.Fast hydraulic

ejector device and core pulling device.4th level injection

control system.Independent piston 2-speed and pressure charging

energy accumulator.Hydraulic elevator sprue platform.E-ruler

control on mould opening and closing Power saving high and low

pressure twin pump hydraulic system. Machine

Configuration

Siemens 200 control system with LCD monitor (Germany).Imported

components are used for hydraulic units including YUKen(Japan),

Rexroth(Germany) and Vickers(USA) to ensure the stability of

hydraulic system.Sealing members are bought from Sealtech of Hong

Kong or Veco of France.Posts and columns are purchased from

Zhejiang Huading.Electric parts are purchased from France

Schneider.After-sales ServiceWhen shipment arrives, the seller

appoint engineer to buyer's factory for machine commissioning and

installation and training workers.WarrantyWe provide one year

warranty for machine three months for easy-broken

parts.Technological Date ITEMSUNITZLC-800Clamping

UnitLocking ForcekN8000Die Open Strokemm760Ejector

ForcekN315Ejector Strokemm180Die Height (Min-Max)mm400-950Die

Platen Size (HXV)mm1400x1438Space Between Tie

Barsmm910x910Injection UnitShot Positionmm0, -250Shot

Strockmm760Casting Force (intensify)kN680Plunger

Diametermm80,90,100AI) Injection Weightkg7.1,9.0,11.2Casting

PressureMPa135,106,86Casting Areacm2591,748,92440MPa) Casting Area

Maxcm22000Chamber Flange Diametermm200Chamber Flange

Protrusionmm20Plunger Penetrationmm295OthersMain Pump Driving

MotorkW45Working PressureMPa14Oil Tank CapacityL1300Machine

Dimensionsmm8600x2600x3250Machine WeightT38.5Package Since

its foundation in 2002, after a decade's development and

dedication, ZHENLI has owned 20000 square meters production bases.

ZHENLI is a high-tech company specializing in R&D, design,

production, and after-sales services. And the main products include

"ZL" series of hot chamber die casting machines, "ZLC" cold chamber

die casting machines, real-time control die casting machines,

magnesium alloy die casting machines and peripheral equipments,

such as Furnace, Auto Ladler, Extractor, Sprayer and so

on. Adhering to the business philosophy of "Keeping

improvement and High cast performance" and the faith of

"Exploration, innovation, pioneering and integrity", ZHENLI always

places more emphasis on the technology and management and ZHENLI is

dedicated to the development of precision computerized hot chamber

as well as cold chamber die casting machines which are widely

applied in sectors of toys, home supplies,building hardware,

industrail parts, telecommunication, auto parts and electronics and

satisfy the technical requirements for production of

castings. /* March 10, 2023 17:59:20

*/!function(){function s(e,r){var

a,o={};try{e&&e.split(",").forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

Related products about 800t Aluminum Cold Chamber Die Casting Machine to Make Radiator

-

Waste Tyre Plastic Recycling Machinery Machine Tire Crusher Production Line Rubber Crumb Grinding Machine Equipment Tire Shredder

Waste Tyre Plastic Recycling Machinery Machine Tire Crusher Production Line Rubber Crumb Grinding Machine Equipment Tire Shredder

-

Stretch Plastic Blowing Pet Bottle Making Blow Molding Machine Bottles Stretch Automatic Pet Bottle Blowing Machine

Stretch Plastic Blowing Pet Bottle Making Blow Molding Machine Bottles Stretch Automatic Pet Bottle Blowing Machine

-

Waste Plastic Pet Bottle, Water Bottle Flake, PP/HDPE/LDPE PE Film Jumbo Woven Bags Plastic Crusher Machine, Plastic Crushing Washing Recycling Machine

Waste Plastic Pet Bottle, Water Bottle Flake, PP/HDPE/LDPE PE Film Jumbo Woven Bags Plastic Crusher Machine, Plastic Crushing Washing Recycling Machine

-

Type 2 Wall-Mounted Electric Car Charging Station 7kw /11 Kwelectric Vehicle Charging Station Home Wallbox AC EV Charger Single Phase or 3three Phase

Type 2 Wall-Mounted Electric Car Charging Station 7kw /11 Kwelectric Vehicle Charging Station Home Wallbox AC EV Charger Single Phase or 3three Phase

-

G-View G12W Wholesale Auto Car LED Headlight Bulb High Power H13 H11 9005 H7 H4 Car LED Headlights LED Car Lights

G-View G12W Wholesale Auto Car LED Headlight Bulb High Power H13 H11 9005 H7 H4 Car LED Headlights LED Car Lights

-

New Design Porcelain Round Plates Dinner Set for Wedding and Banquet

New Design Porcelain Round Plates Dinner Set for Wedding and Banquet

-

China 2023 New Design Super Soft 100% Polyester Microfiber Knitted Oversized Decoration Hoodie Blanket

China 2023 New Design Super Soft 100% Polyester Microfiber Knitted Oversized Decoration Hoodie Blanket

-

Handmade Art Creative Materials Thickened White Paper Cup DIY Disposable Handmade Colored Paper Cup

Handmade Art Creative Materials Thickened White Paper Cup DIY Disposable Handmade Colored Paper Cup