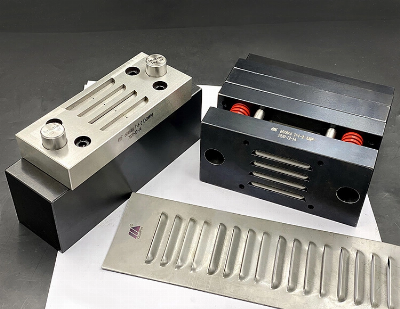

Product

DescriptionMaterial42CrMoHardness45-50HRCOptionBlack-antirustStandardSegmented,

Arc, International Standard, Three Point, Non-Streaking, Adjustable

Groove, Special, etcAvailable Bending Machines ModelAMADA RG100,

TRUMP-TruBend 5000, LVD-HD, FINN-POWER, KOMATS, STRIPPIT,

GASPARINI, TOKYO, ACCURPRESS, YANGLI MB8-100X, YAWEI PBR-100,

JFY PR6CPress brake Forming toolingClosed Louver tool, Opened

Louver tool, Emboss tool, Bridge tool, LOGO tool, Knockout tool, No

indentation tool, RIB tool, Hinge forming tool, Joggle tool, To

flatten tool, R Bending, Z-Bent tool, Multi-V Die, Thick plate

bendingOptionCoating with TICN or TinDelivery time5 - 10 Days

Detailed PhotosForming effect Tooling orderingAccording to

the different requirements of customers, choose the best mold

design program, with the fastest time, the best quality to meet

customer requirements. In addition, if you have difficulties in

selecting a mold, please contact our company. Please provide the

following:1. Detailed shape of the general shape of the finished

product and the bent portion (bending radius, inner contour size,

tolerance range, etc.)2. Material, thickness3. Requirements for

scratches (injuries)4. Machine used for bending (machine model,

maximum tonnage, table length)5. Others, especially need to specify

matters.Upper die interface category:CNC bending tool segmentation,

regular segment specifications are as follows:Mold section 1CNC

bending on the mold: 100 (left), 10,15,20,40,50,200,300,100 (right)

= 835mmCNC bending lower die: 10, 15, 20, 40, 50, 100, 200, 400 =

835mmMold section 2CNC bending on the mold: 100 (left),

10,15,20,40,50,165,300,100 (right) = 800mmProduction Process:Down →

Forging → Tempering → Finishing → Quenching → Annealing →

Conditioning → Coarse Grinding → Finishing → Inspection → Packaging

→ Factory Ordering Information:1. the price and pictures are for

reference only, due to the particularity of the products, different

specifications, different materials, different technical

requirements, prices and pictures are not the same, please be sure

to explain the specification materials and requirements, leave the

way to contact you, We will contact you in time to give you a

quote. 2. When contacting with our customer service staff, please

tell us if you have purchased other products from our factory. Our

company has record records for all customers so that you can easily

find your original order information and save your precious time.

3. In order to provide you with the required products, please

provide the product specifications, models and machine specific

manufacturers, individual precision products also require you to

provide your drawings, pictures or samples. 4. standard parts we

can be shipped within a week, non-standard parts of the cycle,

according to your workpiece is difficult to set! 5. The price and

the picture are for reference only. Actually according to the needs

of the pro, different prices of materials of different

specifications and materials are also different; the postage is

also imaginary, and large-size products generally take the

logistics. Company ProfileDongguan Quapin Hardware

Co.,Ltd.Dongguan Quapin Hardware Co., Ltd is a joint venture, it

specialize in R&D, manufacturing both domestic and abroad CNC

turret punch press tooling (NCT) mould. Quapin is Dongguan one of

the most large-scale CNC turret punch press tooling

manufacturer.QUAPIN is equipped with advance production equipment

and inspection equipment. For example, CNC Center has CNC machining

center, CNC computer lathe, sodick CNC wire-cut machine, CNC EDM

machine, Professional internal grinding, Precision cylindrical

grinder, Precision flat stone mill other other advanced processing

equipment and optical projections, Hardness tester, Sand blasting

machine, Marking machine and other high-precision testing

equipment. After years of efforts, the company established

scientific, high-efficiency, perfect management system as well as

CAD/CAM/UG manufacturing capability.Quapin specializes in the

research, development and manufacturing of CNC turret punch press

molds. We provide one-on-one free technical service, lightning

delivery and intelligent stocking; try our best to help the sheet

metal manufacturing enterprises to increase production efficiency

and minimize the processing cost of each product.We Qaupin products

team silently in the tens of thousands of sheet metal business,

elevator business, sheet metal machine tool business, the world's

top 500 enterprises and other services;Quapin products in the mold

to ensure quality, quality service at the same time, we constantly

innovate! Adhering to do our best to help sheet metal production

enterprises to improve production efficiency, the processing cost

to a minimum!Packaging & ShippingFAQQ: Are you trading company or

manufacturer ?A: We have 11 year experience in the production of

the factory, we are Dongguan mold production base. For the customer

we offer the price of competitive, p

Related products about Press Brake Tooling Louver Forming Die Bending Machine Tool (4 holes)

-

Waste Tyre Plastic Recycling Machinery Machine Tire Crusher Production Line Rubber Crumb Grinding Machine Equipment Tire Shredder

Waste Tyre Plastic Recycling Machinery Machine Tire Crusher Production Line Rubber Crumb Grinding Machine Equipment Tire Shredder

-

Stretch Plastic Blowing Pet Bottle Making Blow Molding Machine Bottles Stretch Automatic Pet Bottle Blowing Machine

Stretch Plastic Blowing Pet Bottle Making Blow Molding Machine Bottles Stretch Automatic Pet Bottle Blowing Machine

-

Waste Plastic Pet Bottle, Water Bottle Flake, PP/HDPE/LDPE PE Film Jumbo Woven Bags Plastic Crusher Machine, Plastic Crushing Washing Recycling Machine

Waste Plastic Pet Bottle, Water Bottle Flake, PP/HDPE/LDPE PE Film Jumbo Woven Bags Plastic Crusher Machine, Plastic Crushing Washing Recycling Machine

-

Type 2 Wall-Mounted Electric Car Charging Station 7kw /11 Kwelectric Vehicle Charging Station Home Wallbox AC EV Charger Single Phase or 3three Phase

Type 2 Wall-Mounted Electric Car Charging Station 7kw /11 Kwelectric Vehicle Charging Station Home Wallbox AC EV Charger Single Phase or 3three Phase

-

G-View G12W Wholesale Auto Car LED Headlight Bulb High Power H13 H11 9005 H7 H4 Car LED Headlights LED Car Lights

G-View G12W Wholesale Auto Car LED Headlight Bulb High Power H13 H11 9005 H7 H4 Car LED Headlights LED Car Lights

-

New Design Porcelain Round Plates Dinner Set for Wedding and Banquet

New Design Porcelain Round Plates Dinner Set for Wedding and Banquet

-

China 2023 New Design Super Soft 100% Polyester Microfiber Knitted Oversized Decoration Hoodie Blanket

China 2023 New Design Super Soft 100% Polyester Microfiber Knitted Oversized Decoration Hoodie Blanket

-

Handmade Art Creative Materials Thickened White Paper Cup DIY Disposable Handmade Colored Paper Cup

Handmade Art Creative Materials Thickened White Paper Cup DIY Disposable Handmade Colored Paper Cup