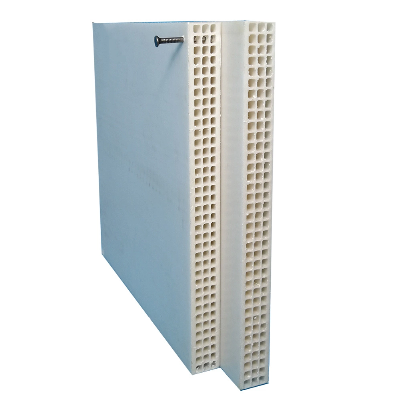

Product DescriptionThe plastic concrete formwork produced by

Sufeng uses polypropylene as basic material,

adding chemicaladditives toughening, flame resistance, weather

resistance and anti-aging, smelt and form

new constructionmaterial through chemical molecular structure

reorganization. Hollow plastic formwork is according to the

principle of structural mechanics, neatly arranged, increasedfour

times support, stronger and more robust;On both sides of the

formwork are right angle processing,increasing the bear capacity,

construction is more convenient. Hollow formwork principle

also makes the product expansion coefficient small.STANDARD

SIZEQuantity in 20ft ContainerQuantity in 40hq

ContainerWeight2440*1220*12MM560 PCS1260 PCS21

KGS/PC2440*1220*15MM450 PCS1120 PCS24 KGS/PC2440*1220*18MM400

PCS900 PCS28 KGS/PC2440*1220*20MM350 PCS850 PCS30 KGS/PCCutting and

customized size are available.1. Light weight, high strength, high

hardness, impact resistance, wear resistance.2. Surface is smooth,

bright and clean; Concreting and forming effect is good for Beizhu

concrete formwork.3. No absorption of moisture, no deformation, no

mildew; Long-term immersion stratification in the water,no bubbles,

sheet size stability, especially suitable for underground and damp

environment.4. Good toughness. Beizhu concrete formwork could be

used as cambered special-shaped formwork.5. Acid and alkali

resistance, corrosion resistance; Beizhu concrete formwork is very

suitable for theengineering application in coastal areas, mine, as

well as seawall. Beizhu concrete formwork needs not doany

preservative treatment both in using and storing the formwork,

which do not pollute the concrete surface.6. The reusable time for

Beizhu concrete formwork can reach more than 60 times, long service

life.7. Waste products can be recycled and reprocessed, making full

use of waste materials. This property cangreatly reduce the project

cost compared with wooden formwork and bamboo formwork.8.

Environmental protection and energy saving, no pollution. No any

poisonous or harmful gas.9. Demould easily. No need brushing

release agent, only tapping, the Beizhu concrete formwork will fall

off.Shorten working hours and speed up the construction schedule

efficiently.10. Easy to process. Sawing, drilling and nailing are

all available. Beizhu concrete formwork can be combinedvertically

and horizontally optionally.11. Easy to remove. Removing is

convenient, quick and safe, and the supporting is also easy to

operate,advantageous to the organization construction, effectively

improving the construction schedule.Product Advantages1.

Waterproof. Won't deform and warp, can be used in damp enviroment;

2. Good strength and toughness. Won't break edges and corners when

mould removal, won't fracture;3. Durable. Can be reused more than

50 times, 1 set formwork can finish whole high buiding 2×30

floors,save 50% total budget than plywood and metal formwork; 4.

Need no releasing agent. Because of incompatibility of plastics and

cement; 5. Light weight. Easier to carry and release worker from

heavy labor. Manual operation, no crane required;6. Surface need no

maintenance. High pressure water jet can be used to flush the

surface;7. High workability. User-friendly, can be nailed, drilled,

cut, etc. Compatible with other materials such asplywood, steel,

aluminum, etc.Installation InstructionsRemark:1) Please use

tungsten steel saw blade with over 80 meshes when you cutting the

plastic formwork.2) Please avoid the peak temperature in one

day when matching the mold. Then the effect after

releasingmould is better.3) Please place the PP formwork as flat as

plywood formwork prevent the deformation after releasing the

mould.4) Please have your building workers skill trained when you

use PP formwork first time. This is an essential part.General

Operation And Notes Of Instrument For Beizhu concrete formwork

:1. Method of use as well as wooden formwork, Beizhu concrete

formwork reinforcement direction with battendirection placed in

cross shaped.2. No need to smear the mold release agent before

using Beizhu concrete formwork.3. When cast-in-place the flat

plate, spacing between the keels should be 20 ~ 25 cm, and the

spacing betweenthe wall plate and keels hould be 10 ~ 20 cm. BEIZHU

Beizhu concrete formwork don't need releasing agent.4. The

seam-line between Beizhuconcrete formwork should be taped.5. The

length of nail should not be too long, generally about 30 ~ 35

mm.6. The strength to drive nailsshould be moderate.7. When

removing the Beizhu concrete formwork, please start from the small

part of one end, the support andthe plates should be removed at the

same time aiming at preventing the template widespread drops, don't

letthe corner drop on the ground vertically.8. The

Sufeng concrete formwork accesses to be mixed used with wood

veneer, bamboo veneer and othermaterial plate.Company ProfileShanxi

SUFENG New Material Technology Co.,Ltd produced plastic

concrete formwork since 2008 andexp

Related products about Construction Tools Building Materials Concrete Fence Mold

-

Waste Tyre Plastic Recycling Machinery Machine Tire Crusher Production Line Rubber Crumb Grinding Machine Equipment Tire Shredder

Waste Tyre Plastic Recycling Machinery Machine Tire Crusher Production Line Rubber Crumb Grinding Machine Equipment Tire Shredder

-

Stretch Plastic Blowing Pet Bottle Making Blow Molding Machine Bottles Stretch Automatic Pet Bottle Blowing Machine

Stretch Plastic Blowing Pet Bottle Making Blow Molding Machine Bottles Stretch Automatic Pet Bottle Blowing Machine

-

Waste Plastic Pet Bottle, Water Bottle Flake, PP/HDPE/LDPE PE Film Jumbo Woven Bags Plastic Crusher Machine, Plastic Crushing Washing Recycling Machine

Waste Plastic Pet Bottle, Water Bottle Flake, PP/HDPE/LDPE PE Film Jumbo Woven Bags Plastic Crusher Machine, Plastic Crushing Washing Recycling Machine

-

Type 2 Wall-Mounted Electric Car Charging Station 7kw /11 Kwelectric Vehicle Charging Station Home Wallbox AC EV Charger Single Phase or 3three Phase

Type 2 Wall-Mounted Electric Car Charging Station 7kw /11 Kwelectric Vehicle Charging Station Home Wallbox AC EV Charger Single Phase or 3three Phase

-

G-View G12W Wholesale Auto Car LED Headlight Bulb High Power H13 H11 9005 H7 H4 Car LED Headlights LED Car Lights

G-View G12W Wholesale Auto Car LED Headlight Bulb High Power H13 H11 9005 H7 H4 Car LED Headlights LED Car Lights

-

New Design Porcelain Round Plates Dinner Set for Wedding and Banquet

New Design Porcelain Round Plates Dinner Set for Wedding and Banquet

-

China 2023 New Design Super Soft 100% Polyester Microfiber Knitted Oversized Decoration Hoodie Blanket

China 2023 New Design Super Soft 100% Polyester Microfiber Knitted Oversized Decoration Hoodie Blanket

-

Handmade Art Creative Materials Thickened White Paper Cup DIY Disposable Handmade Colored Paper Cup

Handmade Art Creative Materials Thickened White Paper Cup DIY Disposable Handmade Colored Paper Cup