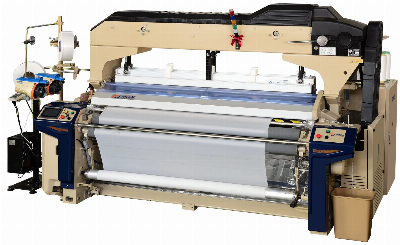

Product Description1,HW-3873 series loom adopts 880cm*880cm*140cm

wall board which reduces the center of gravity of the machine body

and ensure the stable operation of the machine when it is running

with high speed.2,It adopts hollow beating shaft and hyperactivity

beating system,the coiling mechanism is optimized,strengthn the

middle board and back frame,reduce the vibration of loom during

operation;move the reed protection cam outward and improve the

waterprooof effect of the while set machine.3,The width of loom can

reach to 360cm,which is widely used for weaving light and thin

fabrics such as tafetta. Installation InstructionsHaijia

Group has established an intelligent manufacturing model and an

intelligent manufacturing factory in the loom industry, realizing

the deep integration of high-end manufacturing and artificial

intelligence, and becoming a model of intelligent manufacturing in

the loom industry in the West Coast region. Our

AdvantagesHaijia Machinery Group was founded in 1995, focusing on

the field of shuttleless looms. The group currently has two

production bases, Haijia and Century Haijia. The main products

include HW series water jet looms and HA series air jet looms. In

2021, the group's production and sales volume will exceed 12,500

units, and the global market share will reach 20%.According to the

official data of China Textile Machinery Association, the market

share of water jet looms produced by Haijia Group has been leading

the world for many consecutive years. Packaging &

Shipping Product ParametersNo.ItemDescription1Machine

ModelHW-3873,improved based on TSUDOKOMA ZW-300,machine height is

880mm. 2Useful

reed spacereduce 2cm to 65 cm based on reed space.3FrameBox frame

type which features high anti-bending stress.4DriveDirect drive

with rush start motor and magnetic brake.5Main motor:2.2kw for

crank shedding;2.8kw for cam shedding;3.7kw for dobby

shedding.6Push button switches for start,stop,inching and reverse

inching.7Weft insertionFrom one feeder to four feeder.8Water pump

and nozzle jetting device.9Shedding6pcs shaft for crank

shedding;10-12pcs for cam shedding;16pcs for dobby

shedding.10BeatingHW-3873,solid "U"style,75D yarn,max density can

reach 127 pick. 11Let off

&take up Electronic system,improve the fabric

quality.12Creel standFloor mounted,horizontal stand.13TempleTop

mounted,14Electric sectionOptical feeler,induction more

accurate.15Indicator: 4-color lamp for indicating each stopping

causes.16SuctionCloth drying: Slit tube type suction drying system

with mechanical suction motor.17Electronic suction motor work

together.18Panel boardAutomatic data setting, recommended setting

indication, optimim weavingcondition information, automatic

control, troubleshooting, self-diagnosis function operating data

indication, maintenance data condition,7" touch

screen.Accessories1Heald Frame 6pcs for crank

sheddding;10pcs for cam shedding;16pcs for dobby

shedding.2Beam 800mm,1.5pcs each set.3Cloth

Roll 1.5pcs each set.4Reed 1.5pcs each

set.5Heald Wires 10000pcs plastic for each set.6Extra

parts 1000¥ each set./*

March 10, 2023 17:59:20 */!function(){function s(e,r){var

a,o={};try{e&&e.split(",").forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

Related products about High Speed Water Jet Machine for Tafetta in India/Pakistan/Vietnam

-

Waste Tyre Plastic Recycling Machinery Machine Tire Crusher Production Line Rubber Crumb Grinding Machine Equipment Tire Shredder

Waste Tyre Plastic Recycling Machinery Machine Tire Crusher Production Line Rubber Crumb Grinding Machine Equipment Tire Shredder

-

Stretch Plastic Blowing Pet Bottle Making Blow Molding Machine Bottles Stretch Automatic Pet Bottle Blowing Machine

Stretch Plastic Blowing Pet Bottle Making Blow Molding Machine Bottles Stretch Automatic Pet Bottle Blowing Machine

-

Waste Plastic Pet Bottle, Water Bottle Flake, PP/HDPE/LDPE PE Film Jumbo Woven Bags Plastic Crusher Machine, Plastic Crushing Washing Recycling Machine

Waste Plastic Pet Bottle, Water Bottle Flake, PP/HDPE/LDPE PE Film Jumbo Woven Bags Plastic Crusher Machine, Plastic Crushing Washing Recycling Machine

-

Type 2 Wall-Mounted Electric Car Charging Station 7kw /11 Kwelectric Vehicle Charging Station Home Wallbox AC EV Charger Single Phase or 3three Phase

Type 2 Wall-Mounted Electric Car Charging Station 7kw /11 Kwelectric Vehicle Charging Station Home Wallbox AC EV Charger Single Phase or 3three Phase

-

G-View G12W Wholesale Auto Car LED Headlight Bulb High Power H13 H11 9005 H7 H4 Car LED Headlights LED Car Lights

G-View G12W Wholesale Auto Car LED Headlight Bulb High Power H13 H11 9005 H7 H4 Car LED Headlights LED Car Lights

-

New Design Porcelain Round Plates Dinner Set for Wedding and Banquet

New Design Porcelain Round Plates Dinner Set for Wedding and Banquet

-

China 2023 New Design Super Soft 100% Polyester Microfiber Knitted Oversized Decoration Hoodie Blanket

China 2023 New Design Super Soft 100% Polyester Microfiber Knitted Oversized Decoration Hoodie Blanket

-

Handmade Art Creative Materials Thickened White Paper Cup DIY Disposable Handmade Colored Paper Cup

Handmade Art Creative Materials Thickened White Paper Cup DIY Disposable Handmade Colored Paper Cup