Paper machine clothingsCompany ProfileHuatao Group is set up

in 2008. The main business is to serve the pulp and paper industry

by providing quality accessories and paper machine

innovation services to help customers solve various problems

in production, improve production efficiency and reduce energy

consumption.Huatao Group has a professional technician team

that is devoted to the pulp and paper industry. We are

able to make the best proposal after completely analyzing and

figuring out our problems of the paper production line though

paper-making progress, equipment, electric automatization, and so

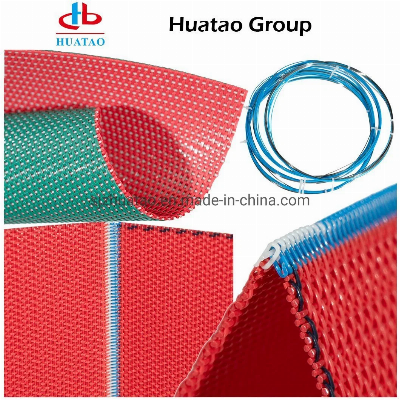

forth.Product DescriptionThe forming fabric / Forming wire or

"wire" of a paper machine is the continuous belt or belts of mesh

screen upon which the paper sheet is formed. Most modern forming

fabrics are no longer comprised of metal wires. Rather, they are

comprised of polyester monofilament. The weave pattern and layering

of a forming fabric is designed to meet stringent requirements of

dimensional stability, resistance to abrasion (on the wire side),

minimum resistance to drainage, minimum wire mark, and

(sometimes) maximization of retention of fiber

fines. Traditional Fourdrinier paper machines have a

single wire. Modified Fourdriniers and gap

formers can have two.Forming fabric is very important for a

paper machine in a paper mill. In the general formation of paper

depends on wire cloth and refining of paper pulp. Paper machine

wire cloth (forming fabric) made from polyester or polyamide

monofilaments. To shape an uninterrupted belt, it is made by

endless of a seam. During woven of forming fabric, filaments are

composed of the paper machine direction and paper machine cross

direction. The filaments of paper machine direction or lengthwise

are called warp. One the other hand the filaments of paper machine

cross direction are called weft or Shute or filling. The

construction of wire cloth depends on some weaving variables such

as pattern, mesh, yarn, diameter, degree of crimping etc. Mesh is

very important for a wire cloth (forming fabric). Water drainage

and retention of fibers depend on it.According to the category,

forming fabric can be divided into single layer wire cloth, 1.5

layer wire cloth, double layer wire cloth, two and a half layer

wire cloth, triple layer wire cloth, and 2.5 layer wire cloth.In

accordance with weaving, wire cloth (forming fabric) can be divided

into 2-shed, 4-shed, 5-shed, 7-shed, 8-shed, 16-shed, 24-shed etc.

A paper machine wire cloth has two surfaces. One is the forming

surface or top surface and another is the wearing surface or

underside surface.Depending on paper machine and various paper

grades wire cloth also difference. The uses of triple layer wire

cloth (forming fabric) is increasing day by day. Dryer

Screen, FeltDryer Fabric / Dryer Screen / Spiral Dryer Fabric /

Woven Dryer Canvas Huatao provides polyester spiral

belt made from first-class monofilament, in reference to

Finland Standard, which has the characteristics of stable

properties and long work time.Advantages of Polyester Spiral

Belt :Flat surface, not easily crackedGood air

permeabilityStable property against heat and moistureLow thermal

shrinkingLess elongation at heatLong lifespanWoven Dryer

ScreenAccording to the weaving, polyester dryer

fabric can be divided into 3-shed, and 4-shed. According to

the category, polyester dryer fabric can be divided into

one and a half layer, double layer, and rectangular wire fabric.

According to the joining mode, it can be divided into insert, pin,

pin ring and spiral ring join. 3-shed one layer and a

half polyester dryer fabric are suitable for drying

papers below 70g. 4-shed double layer polyester dryer

fabric is suitable for drying papers above 70g.

Rectangular wire polyester dryer fabric is suitable for

the fore several heating boxes of the drying zone, quality papers

can use all.Press felt / paper making felt / BOM felt / Seam felt /

Seamed felt / Endless felt / Pick up feltThere are three series of

BOM papermaking felts available in the market. They are

single-layer base mesh, double-layer base mesh and multi-layer base

mesh. According to their structures, they can be divided into BOM

formed felt, BOM pressed felt, BOM upper felt, BOMdryer felt, BOM

pulp board felt, and so on.BOM paper-making felts are generally

made of the base mesh layer and the fiber layer. The base mesh can

be single, double, or multi-layers. The double base meshlayer can

also have a 1+1 laminated. The multi-layer base mesh can also be

divided into 1+2 or 2+2 laminated. All mesh bases are woven with

monofilament or twisted monofilament yarns. The fiber layers are

woven with different sizes of polyamide fibers. Fiber layers and

base mesh layer are attached by needle stitching to form the

feltDetailed Photos Our Professional Team/* March 10, 2023

17:59:20 */!function(){function s(e,r){var

a,o={};try{e&&e.split(",").forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

Related products about Paper Machine Clothing Woven Dryer Fabric with Round & Flat Thread

-

Waste Tyre Plastic Recycling Machinery Machine Tire Crusher Production Line Rubber Crumb Grinding Machine Equipment Tire Shredder

Waste Tyre Plastic Recycling Machinery Machine Tire Crusher Production Line Rubber Crumb Grinding Machine Equipment Tire Shredder

-

Stretch Plastic Blowing Pet Bottle Making Blow Molding Machine Bottles Stretch Automatic Pet Bottle Blowing Machine

Stretch Plastic Blowing Pet Bottle Making Blow Molding Machine Bottles Stretch Automatic Pet Bottle Blowing Machine

-

Waste Plastic Pet Bottle, Water Bottle Flake, PP/HDPE/LDPE PE Film Jumbo Woven Bags Plastic Crusher Machine, Plastic Crushing Washing Recycling Machine

Waste Plastic Pet Bottle, Water Bottle Flake, PP/HDPE/LDPE PE Film Jumbo Woven Bags Plastic Crusher Machine, Plastic Crushing Washing Recycling Machine

-

Type 2 Wall-Mounted Electric Car Charging Station 7kw /11 Kwelectric Vehicle Charging Station Home Wallbox AC EV Charger Single Phase or 3three Phase

Type 2 Wall-Mounted Electric Car Charging Station 7kw /11 Kwelectric Vehicle Charging Station Home Wallbox AC EV Charger Single Phase or 3three Phase

-

G-View G12W Wholesale Auto Car LED Headlight Bulb High Power H13 H11 9005 H7 H4 Car LED Headlights LED Car Lights

G-View G12W Wholesale Auto Car LED Headlight Bulb High Power H13 H11 9005 H7 H4 Car LED Headlights LED Car Lights

-

New Design Porcelain Round Plates Dinner Set for Wedding and Banquet

New Design Porcelain Round Plates Dinner Set for Wedding and Banquet

-

China 2023 New Design Super Soft 100% Polyester Microfiber Knitted Oversized Decoration Hoodie Blanket

China 2023 New Design Super Soft 100% Polyester Microfiber Knitted Oversized Decoration Hoodie Blanket

-

Handmade Art Creative Materials Thickened White Paper Cup DIY Disposable Handmade Colored Paper Cup

Handmade Art Creative Materials Thickened White Paper Cup DIY Disposable Handmade Colored Paper Cup