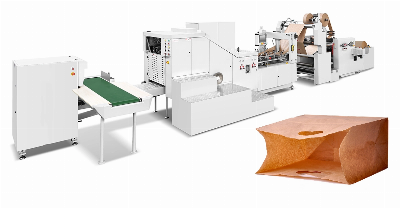

Product DescriptionThe machine is used for roll raw

color paper or printing roll paper such as kraft paper, food paper

and other paper rolls by the machine once complete the paper bag

process. By automatic paper roll tension, coil correction, Paiqi

bag positioning on the glue patch, center on glue, printing bag

tracking. Raw materialinto into a barrel, Paiqi bag buckle hand

hole, fixed long cut, bottom indentation, bottom folding bottom,

bottom on glue. The bottom of the bag is formed, the finished bag

is finishing once completed. Native operation is more convenient,

more efficient, more stable, is the production of a variety of

different paper bags, leisure food bags, bread bags, dry fruit bags

and so on environmentally automatic fully automatic paich bag paper

bag machine equipmentSchematic Diagram

ParameterParameter NameDC-330DDC-450D Cutting Length

270-530mm270-530mm Bag Width 120-330mm210-450mm Bottom Width

60-180mm90-180mm Paper Thickness 60-150g/m^280-150g/m^2 Machine

Speed 30-220pcs/min30-180pcs/min Production Speed

30-200pcs/min30-160pcs/min Paper Roll Width 450-1050mm590-1290mm

Patch Bag Width 190-330mm220-450mm Patch Handle Length

75/85mm75/85mm Paige Bag Paper Thickness 80-150g/m^280-150g/m^2

Paige Bag Film Thickness 40-70μm40-70μm Paige Bag Roll Width

130mm130mm Paige Bag Roll Straight 500mm500mm Patch Bag Speed

30-130pcs/min30-130pcs/min Roll Paper Diamter 1200mm1200mm Machine

Power 3phase 4line 380v 40.6kw3phase 4line 380v 40.6kw Machine

Weight 9000kg9000kg Machine Size

12000x3750x2000mm1300x3750x2000mmSampleDetails√ Use France

SCHNEIDER touch screen human-computer interface, making

the machine easy to operate and

control.√ Adopt Germany original LENZE PC control,

integrated with optical fiber. Thus ensure stable

and high speed

running.√ Adopt Germany original LENZE servo

motor and German original SICK photoelectric eye

correction, tracking printing bag

accurately.√ Patch bag function adopts a

complete set

of German original LENZE servo motor. Through

integration with optical fiber, it works with the

German original Rexroth motion

controller (PC).√ Automatic hole-punching

adopts Germany original LENZE servo motor.√ Raw

material unwinding EPC adopts Italy SELECTRA,

reducing material alignment time.Company ProfileOur HistoryIn

2010, in response to global environmental protection and green

packaging, we started open up a new field of non-woven machinery,

becoming the first choice of customers. During the past many years,

TINUO specializes in manufacturing non-woven bag making machines,

paper bag machines, printing machines and different machines in

packaging & printing industry. In 2020, we made timely adjustments

to the challenges posed by the epidemic. Since 2021, we have

constantly updated our products to make them more intelligent and

environmentally friendly to provide the best quality, greenest and

most cost-effective solutions for the whole packaging industry as

well as each of our customers and always uphold the win-win

cooperation concept.Our FactoryWe have a factory with a

professional R&D team and production team to manufacture more

advanced intelligent machines. In the production process of bag

making machines, we pay attention to every detail and quality

control of the production line. Our large investment technology

allows us to produce parts that meet the exacting standard required

to build a precision machines.Our Advantage1.China Top

3 packaging machinery Manufacturer2.We have 12 years of

experience3.We have more than 80 patents4.We are willing and able

to customize machines5.Our sales volume is the first place in the

worldOur CertificateClosely with international advanced technology

production technology, TINUO has more than 80 patents, due to the

changing of market demands, we willing and able to customize the

machines. All production from us have passed ISO9001:2000, CE, B.V,

SGS and GMC. With rich technology and capital resources, we pay

high attention to the new product innovation.Our ProductNON-WOVEN

PACKAGE MAKING MACHINERYPAPER PACKAGE MAKING MACHINERYPLASTIC

PACKAGE MAKING MACHINERYPRINTING MACHINERYLAMINATING

MACHINESSLITTING MACHINESGENERAL PACKAGE MAKING MACHINERYAfter

sales service Q & A--How to install the equipment?--Due the corona

breakout in global, the seller would not arrange engineer outside

to install, all the service would change to online service.--If the

corona finished,how to install? And how long it will last?--The

seller will send 1 engineer to install, test the machine and train

customers' workers in buyers' factory.It will take about 1 week for

the entire installation and training.--What are the additional

costs of installation?--The buyer should cover engineers' salary,

visa cost, Round air tickets, accommodations, transportation in

buyers' country, food, medical care, safety cost, and related cost

happens in buyers' country. Also, the buyer should prepare enough

labor, electric wire outside the control panel and tools for

installations.--What a

Related products about Price Automatic High Speed Square Bottom Paper Bag Machine (Die Cut Handle)

-

Waste Tyre Plastic Recycling Machinery Machine Tire Crusher Production Line Rubber Crumb Grinding Machine Equipment Tire Shredder

Waste Tyre Plastic Recycling Machinery Machine Tire Crusher Production Line Rubber Crumb Grinding Machine Equipment Tire Shredder

-

Stretch Plastic Blowing Pet Bottle Making Blow Molding Machine Bottles Stretch Automatic Pet Bottle Blowing Machine

Stretch Plastic Blowing Pet Bottle Making Blow Molding Machine Bottles Stretch Automatic Pet Bottle Blowing Machine

-

Waste Plastic Pet Bottle, Water Bottle Flake, PP/HDPE/LDPE PE Film Jumbo Woven Bags Plastic Crusher Machine, Plastic Crushing Washing Recycling Machine

Waste Plastic Pet Bottle, Water Bottle Flake, PP/HDPE/LDPE PE Film Jumbo Woven Bags Plastic Crusher Machine, Plastic Crushing Washing Recycling Machine

-

Type 2 Wall-Mounted Electric Car Charging Station 7kw /11 Kwelectric Vehicle Charging Station Home Wallbox AC EV Charger Single Phase or 3three Phase

Type 2 Wall-Mounted Electric Car Charging Station 7kw /11 Kwelectric Vehicle Charging Station Home Wallbox AC EV Charger Single Phase or 3three Phase

-

G-View G12W Wholesale Auto Car LED Headlight Bulb High Power H13 H11 9005 H7 H4 Car LED Headlights LED Car Lights

G-View G12W Wholesale Auto Car LED Headlight Bulb High Power H13 H11 9005 H7 H4 Car LED Headlights LED Car Lights

-

New Design Porcelain Round Plates Dinner Set for Wedding and Banquet

New Design Porcelain Round Plates Dinner Set for Wedding and Banquet

-

China 2023 New Design Super Soft 100% Polyester Microfiber Knitted Oversized Decoration Hoodie Blanket

China 2023 New Design Super Soft 100% Polyester Microfiber Knitted Oversized Decoration Hoodie Blanket

-

Handmade Art Creative Materials Thickened White Paper Cup DIY Disposable Handmade Colored Paper Cup

Handmade Art Creative Materials Thickened White Paper Cup DIY Disposable Handmade Colored Paper Cup