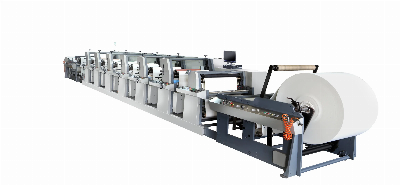

Function Units Unwinding UnitUnwinding method of single-unit

air-expanding shaft for base paper feeding rackLoading method of

convex key type air expanding shaftRewinding uses magnetic powder

brake and automatic tension control to achieve constant tension

control.Early warning of material change (automatic warning of too

small unwinding diameter)Paper breaking shutdown deviceEquipped

with a rapid inflatable gunDeviation correction system: can

automatically correct the position of paper; Detection method: edge

checkingPaper bonding platform, easy to operateHydraulic loading

and unloading device2. Web Guide SystemPaper Splicing Table : with

pneumatic paper holding device.Ball screw electric actuatorAdopt

the photoelectric sensor for web guide transmissionElectronic web

guide traction device. If there is any excursion in paper

feeding,the system will have a constant and accurate

adjustmentAdopt closed loop control system to accurately detect the

deviation and correct itHard Anodization to the paper guide HV

800-1000Inspection:the edgeWeb Guide

precision:±0.02mm3. In-feed Tension Control UnitUse the double

side pressure rubber roller to clutch and feed paper and to ensure

the tension Printing Units(shaft system) The machine double

sides frame is made of overall alloy and cast iron, which improves

the stable performance and durability of the press machineHigh

precision ceramic anilox roll with micro-metric adjustmentReversed

single doctor bladeAnilox roll and printing cylinder separation and

reunion pneumaticallyself-cleaning plate feature.The anilox and

plate cylinders release alternately, transfering residual ink to

the paper when machine stop, leaving the printing plates clean and

minimizing the need of hand to clean the plates When press stops,

the anilox roll continuous running. Hence avoiding permanent

damage, which is caused by ink drying on the anilox surface5.

Drying UnitsEvery printing unit has one separate drying unitHigh

efficiency drying unit including infra red lamps, air

blowing/suction system. Air intake adjustable, Air circulation

design on the exhaust, the blower is adjustableShort wave infrared

heating elementsNatural air blowing assembly with exhaust fan6.

Video Web Inspection SystemVideo is high efficiency and

synchronous, can be moved left and rightWith 14 inch monitor one

pcone stroboscope lampIt can be enlarged 18 times of image7.Out

Feed Tension Control SystemThe rear tension unit is made of alloy

and cast ironUse the double side pressure rubber to clutch and feed

and to guarantee the stale tension8.Rewinding Unitrewind unit

60''(1524mm)capacity, with 3'' shaftHydraulic roll liftWeb break

sensor, automatically shut down when paper broken.9. Automatic

Lubricating SystemThe gear's automatic dampening system can adjust

the lubricating time and rationWhen the dampening system breaks

down or the lubrication is not enough, the indicator will alarm

automatically.Technical

Parameters:Specification650920102012201320Max. Web

Width650mm920mm1020mm1220mm1320mmMax. Printing

Width600mm900mm1000mm1200mm1300mmMax Die-Cutting

Width600mm900mm1000mm1200mm1300mmPrinting

Repeat286-1200mm286-1200mm286-1200mm286-1200mm286-1200mmMax.Unwinder

Diameter1524mm1524mm1524mm1524mm Max.Rewinder

Diameter1524mm1524mm1524mm1524mm1524mmGearing1/8cp1/8cp1/8cp1/8cp1/8cpMax

Printing Speed150m/min150m/min150m/min150m/min150m/minDiameter of

web roller100mm100mm100mm100mm100mmDrying modeWarm Drying/IR

Drying/ UV DryingOil usedAqueous ink/ UV InkPower Requirement380V

3PH 50HzSubstrate17g copy paper, cotton paper, 80-450g chrome

paper, aluminum-foil paper, BOPP, PET, paper board, kraft

paper /* March 10, 2023 17:59:20 */!function(){function

s(e,r){var

a,o={};try{e&&e.split(",").forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

Related products about Automatic Exercise Book Making Reel Paper Flexography Printing Machine

-

Waste Tyre Plastic Recycling Machinery Machine Tire Crusher Production Line Rubber Crumb Grinding Machine Equipment Tire Shredder

Waste Tyre Plastic Recycling Machinery Machine Tire Crusher Production Line Rubber Crumb Grinding Machine Equipment Tire Shredder

-

Stretch Plastic Blowing Pet Bottle Making Blow Molding Machine Bottles Stretch Automatic Pet Bottle Blowing Machine

Stretch Plastic Blowing Pet Bottle Making Blow Molding Machine Bottles Stretch Automatic Pet Bottle Blowing Machine

-

Waste Plastic Pet Bottle, Water Bottle Flake, PP/HDPE/LDPE PE Film Jumbo Woven Bags Plastic Crusher Machine, Plastic Crushing Washing Recycling Machine

Waste Plastic Pet Bottle, Water Bottle Flake, PP/HDPE/LDPE PE Film Jumbo Woven Bags Plastic Crusher Machine, Plastic Crushing Washing Recycling Machine

-

Type 2 Wall-Mounted Electric Car Charging Station 7kw /11 Kwelectric Vehicle Charging Station Home Wallbox AC EV Charger Single Phase or 3three Phase

Type 2 Wall-Mounted Electric Car Charging Station 7kw /11 Kwelectric Vehicle Charging Station Home Wallbox AC EV Charger Single Phase or 3three Phase

-

G-View G12W Wholesale Auto Car LED Headlight Bulb High Power H13 H11 9005 H7 H4 Car LED Headlights LED Car Lights

G-View G12W Wholesale Auto Car LED Headlight Bulb High Power H13 H11 9005 H7 H4 Car LED Headlights LED Car Lights

-

New Design Porcelain Round Plates Dinner Set for Wedding and Banquet

New Design Porcelain Round Plates Dinner Set for Wedding and Banquet

-

China 2023 New Design Super Soft 100% Polyester Microfiber Knitted Oversized Decoration Hoodie Blanket

China 2023 New Design Super Soft 100% Polyester Microfiber Knitted Oversized Decoration Hoodie Blanket

-

Handmade Art Creative Materials Thickened White Paper Cup DIY Disposable Handmade Colored Paper Cup

Handmade Art Creative Materials Thickened White Paper Cup DIY Disposable Handmade Colored Paper Cup