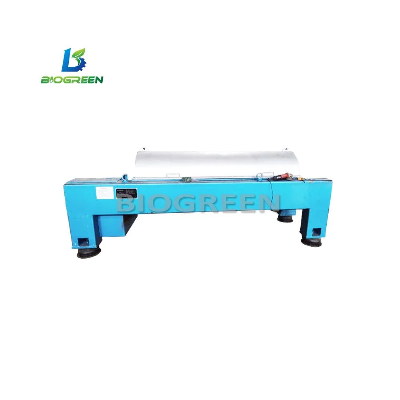

Horizontal centrifuge principle: The feed suspension is

introduced through an inlet pipe into the feed zone of the conveyor

where it is accelerated and directed into the interior of the bowl.

The settled solids are conveyed axially towards the small end of

the bowl by means of the screw conveyor, which rotates at a

slightly different speed than the bowl. On the way to the discharge

ports the solids are lifted out of the pond up along the dry beach.

The solids are finally discharged from the bowl through the

discharge ports into the collecting chamber of the casing that

surrounds the bowl. From there the solids are removed by gravity

through the outlet funnel. The liquid phase forming a hollow

cylinder due to the centrifugal force, and flows towards the large

end of the bowl. There the liquid overflows adjustable plate dams

into the centrate chamber of the casing and is discharged by

gravity. Horizontal centrifuge characteristics:All parts coming

into contact with the product are made of stainless steel.3-phase

AC motor for controlled torque starting via frequency converterBowl

speed is adjustable via VFD to obtain the required G-force for

optimized separationPond depth in the bowl is adjustable for

optimized balance between liquid clarity and solids

drynessConveying speed is adjustable for optimized balance between

liquidLow personnel costs due to continuous and automatic

operation.Highest g-force for higher solids outputAutomatic

adjustment of differential speed via VFDTwo motor driveBelts for

both primary motor and secondary motorApplication:Drilling mud,

environmental protection sewage, oily sludge, cutting fluid, sand

washing water, mineral washing water, soda whitemud, salt mud

dewatering, magnesium aluminum emulsion, steel-making wastewater,

precision casting wastewater, constructionmud, tunnel mud, mine

wastewater, industrial wastewater, organic wastewater, aquaculture

wastewater, chemical industrialwastewater, printing and dyeing

wastewater, municipal sewage, river sludge, water plant sludge,

lake sludge, kaolin grading,calcium carbonate, bentonite, Silica,

titanium dioxide, calcium sulfate, barium sulfate, conductive film

glass polishing solution,aluminum hydroxide, cryolite, silicate,

oil sand separation, landing oil, oil sludge, coal tar, inorganic

fertilizer, Chinese medicineextraction such as taxus chinensis,

honeysuckle and liquorice, clarification, concentration and

dehydration of salt crystals, Pineapple stem solution,Separation of

fruit juice,etc.Equipment parameters: ModelBowl

speed(rpm)Separation factorCapacity(m3/h)Solids

removal(m3/h)Primary

motor (Kw)Dimension(mm)Weight(Kg)2204800~54002000~35003~50.4111600×1100×8507603004200~46003~150.811~152470×1230×85015003503700~42005~201.25~222790×1300×88020004003200~39005~30218.5~302950×1400×88026004503000~37005~452.522~373300×1500×92032005302700~345010~80530~553730×1600×11005200

/* March 10, 2023 17:59:20 */!function(){function s(e,r){var

a,o={};try{e&&e.split(",").forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

Related products about Continuous Horizontal Decanter Centrifuge for Sludge with Screw Discharging

-

Waste Tyre Plastic Recycling Machinery Machine Tire Crusher Production Line Rubber Crumb Grinding Machine Equipment Tire Shredder

Waste Tyre Plastic Recycling Machinery Machine Tire Crusher Production Line Rubber Crumb Grinding Machine Equipment Tire Shredder

-

Stretch Plastic Blowing Pet Bottle Making Blow Molding Machine Bottles Stretch Automatic Pet Bottle Blowing Machine

Stretch Plastic Blowing Pet Bottle Making Blow Molding Machine Bottles Stretch Automatic Pet Bottle Blowing Machine

-

Waste Plastic Pet Bottle, Water Bottle Flake, PP/HDPE/LDPE PE Film Jumbo Woven Bags Plastic Crusher Machine, Plastic Crushing Washing Recycling Machine

Waste Plastic Pet Bottle, Water Bottle Flake, PP/HDPE/LDPE PE Film Jumbo Woven Bags Plastic Crusher Machine, Plastic Crushing Washing Recycling Machine

-

Type 2 Wall-Mounted Electric Car Charging Station 7kw /11 Kwelectric Vehicle Charging Station Home Wallbox AC EV Charger Single Phase or 3three Phase

Type 2 Wall-Mounted Electric Car Charging Station 7kw /11 Kwelectric Vehicle Charging Station Home Wallbox AC EV Charger Single Phase or 3three Phase

-

G-View G12W Wholesale Auto Car LED Headlight Bulb High Power H13 H11 9005 H7 H4 Car LED Headlights LED Car Lights

G-View G12W Wholesale Auto Car LED Headlight Bulb High Power H13 H11 9005 H7 H4 Car LED Headlights LED Car Lights

-

New Design Porcelain Round Plates Dinner Set for Wedding and Banquet

New Design Porcelain Round Plates Dinner Set for Wedding and Banquet

-

China 2023 New Design Super Soft 100% Polyester Microfiber Knitted Oversized Decoration Hoodie Blanket

China 2023 New Design Super Soft 100% Polyester Microfiber Knitted Oversized Decoration Hoodie Blanket

-

Handmade Art Creative Materials Thickened White Paper Cup DIY Disposable Handmade Colored Paper Cup

Handmade Art Creative Materials Thickened White Paper Cup DIY Disposable Handmade Colored Paper Cup