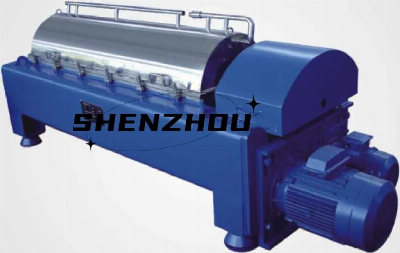

Our company is the largest producer of the decanter centrifuge in

China!Introduce of the machine as following:LW Horizontal Decanter

Centrifuges feature continuous feeding and discharge . This

chemical separation equipment has been applied

two-phase(solid-liquid) and three-phase(solid-liquid-liquid)

slurries separation industry of chemicals, pharmaceutical,

environment protection, as well as mining and food,

etc.Advantage1. This liquid clarifying device adopts

horizontal design which balances the layout of electric motor

and bowl. As a result, outstanding operation

stability generates minimized vibration.2. Dual

eletric motor control enables stepless speed adjustment on bowl and

spiral components.3. Scroll conveyor flight inside

this continuous centrifuge is painted by abrasion resistant alloy

or welded by hard alloy. Moreover, main components on our

horizontal decanter centrifuge, such as rotating bowl and spiral

parts, are made from corrosion resistant stainless steel or dual-

phase steel, whereby offering exceptional speed limits and

separation ratio.4. Our mud dewatering equipment

comes with three options including cycloidal gear, planetary gear

and hydraulic differential, resulting in large rang of differential

adjustment. Therefore, this industrial centrifuge can be

applible to diverse solids.5. Multipe

protections are available on our horizontal decanter centrifuge to

ensure operation safety, including over-vibratation protection,

bearing temperature detection, screw conveyor torque

protection rotating and differential speed detection, as well as

nitrogen-filled explosion- proof protection, motr overload

and over heat protection.6. JG type rubber

shock absorber requires no anchor bolts.Application

1. industrial and municipal wastewater

treatment 2. oil&gas

drilling mud/fluid control

3. washing, separation and dewater of

starch 4. mycelium and

zymtotic fluid separation for antibiotic

5. dewatering of soybean and wheat

protein 6. dewatering of fish

power and fish meat

7. dewatering of vinasse

8. clarification and extraction of

fruit juice 9. separation and

purification for animal and vegetable oil 10.production and

purification of olive oil, palm oil, avcado oil 11.separation

and purification for coal tar 12.grading of kaolin and

grapgite 13.grading and dewatering of dyestuff and

pigment 14.froth flotation for cleaned coal and dewatering of

coal mud 15.grading and dewatering of

minerals Structural Diagram Technical

Paramter:ModelTechnical parametermotor poweroutline

dimension(mm)Machine weight(KG)(Diameter)mmRotation speedrpmLength

mmSeparation factorGcapacityM3/hMain motor KWVice

motorKWDimension:L×D×HLW250×10002503600100018131-37.5/114/5.52065×1050×8001100LW360×12003603500120024673-811/18.57.5/112600×1500×8501900LW360×15003603500150020623-811/18.57.5/112800×1400×8502000LW420×17504203200175024064-2030/3711/18.53120×1580×10503000LW450×16004503200160025785-2530/4511/223780×1050×11803500LW450×18004503200180025785-2530/4511/223985×1050×11803600LW450×20004503000200022665─2530/4511/224320×1050×11803800LW500×180050030001800251710-3037/5515/224200×1110×12004300LW500×210050030002100251710-3037/5515/224500×1110×12004500LW550×180055030001800276910-3545/5518.5/224380×1160×12304800LW550×220055028002200241210-3545/5518.5/304780×1160×12305000LW650×175065020001750145420-5075/9030/374576×1300×12506000LW650×200065020002000145420-5075/9030/374900×1300×12506200LW800×200080018002000145040-10090/11045/556052×1460×210010000LW1000×2350100016002350143250-140110/13255/756850×1860×230012800More

parts show of the decanter centrifuge: Our

services As Follows:Provide free technical training,

guidance and information of accessories.Our technical staff could

instruct our customers on the installation of connector and

accessories on site, and deal with technical and quality

issues.Once receive the customer complaints, we will response

within 24 hours.Free maintenance and replacement will be provided

if defects result from quality failure of our product.Our company

will provide perfect after-sale services and technical

support. FAQ Q1: Where can I get product & price

information? A1: Send us inquiry or email directly, then we will

contact you. Q2: How can I make sure your machinery is suitable for

me? A2: Please tell all the separation information you know,

such as your raw liquid, two-phase or three-phase separation, solid

content in liquid, solid size, the purpose, etc. After analyzing

your information, we will to choose a suitable model for you, and

send the details and videos to you. Q3: What should I do if I want

to see the separation effect? A3: If you can come to our factory

with the raw liquid, we will provide test service. Or you deliver

the raw liquid to us, and we will do a test, and supply you the

testing videos. Q4: How to enjoy the OEM services? A4: As the

manufacturer of the machine, we will try our best to satisfy you if

you have any spe

Related products about Made in China Horizontal Decanter Centrifuge

-

Waste Tyre Plastic Recycling Machinery Machine Tire Crusher Production Line Rubber Crumb Grinding Machine Equipment Tire Shredder

Waste Tyre Plastic Recycling Machinery Machine Tire Crusher Production Line Rubber Crumb Grinding Machine Equipment Tire Shredder

-

Stretch Plastic Blowing Pet Bottle Making Blow Molding Machine Bottles Stretch Automatic Pet Bottle Blowing Machine

Stretch Plastic Blowing Pet Bottle Making Blow Molding Machine Bottles Stretch Automatic Pet Bottle Blowing Machine

-

Waste Plastic Pet Bottle, Water Bottle Flake, PP/HDPE/LDPE PE Film Jumbo Woven Bags Plastic Crusher Machine, Plastic Crushing Washing Recycling Machine

Waste Plastic Pet Bottle, Water Bottle Flake, PP/HDPE/LDPE PE Film Jumbo Woven Bags Plastic Crusher Machine, Plastic Crushing Washing Recycling Machine

-

Type 2 Wall-Mounted Electric Car Charging Station 7kw /11 Kwelectric Vehicle Charging Station Home Wallbox AC EV Charger Single Phase or 3three Phase

Type 2 Wall-Mounted Electric Car Charging Station 7kw /11 Kwelectric Vehicle Charging Station Home Wallbox AC EV Charger Single Phase or 3three Phase

-

G-View G12W Wholesale Auto Car LED Headlight Bulb High Power H13 H11 9005 H7 H4 Car LED Headlights LED Car Lights

G-View G12W Wholesale Auto Car LED Headlight Bulb High Power H13 H11 9005 H7 H4 Car LED Headlights LED Car Lights

-

New Design Porcelain Round Plates Dinner Set for Wedding and Banquet

New Design Porcelain Round Plates Dinner Set for Wedding and Banquet

-

China 2023 New Design Super Soft 100% Polyester Microfiber Knitted Oversized Decoration Hoodie Blanket

China 2023 New Design Super Soft 100% Polyester Microfiber Knitted Oversized Decoration Hoodie Blanket

-

Handmade Art Creative Materials Thickened White Paper Cup DIY Disposable Handmade Colored Paper Cup

Handmade Art Creative Materials Thickened White Paper Cup DIY Disposable Handmade Colored Paper Cup