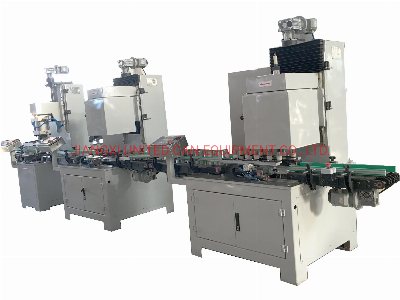

AUTOMATIC ROUND CAN MAKING MACHINE LINESpecfication:Capacity42/60

cans/minDiameter52-190mmMax height280mmTinplate

thickness≤0.4mmMotor Power30kw

No. MachineQuantity(sets)1Gang Slitter12Automatic roller

& welder13Water chiller14Automatic flanging machine15Automatic

seamers26Automatic spot welders1 Automatic single slitterThis

slitter can be used for trimming and cutting sheet into strip

type as well. Machine dimension :6000x1600x1800mmMotor

power : 5.5KW, 380,50/60HZCutting width : 1050mmCutting size Max :

1100x1100mmSpeed : 50 pieces per minTotal weight : 5000 kgsFeeing

device introduction : With loading weight of 3 TON.With

auto-lift in feeding lid.And auto-down at lastpiece. With double

sheet detective and brake motor.With magnetic to seperate. 2,

Feeding conveyor with rectify table.3, Slitter Cutting balde :

Cr12Mov Sheet size : 42-1200mmCutting blade : 7 pcs4,

Stacking device With loading weight of 3 TON. Can be used

for strip or trimming sheet stacking.Stacking down

automatically.Stacking parts has the roller installed.2,Automatic

seam welders Model:FH18-65Power:3N380V/50HZ-10KVAWelding

speed:6-12m/minCapacity:20-50cans/minDiameter:¢52-180mmHeight:200--450mmOverlap:0.8-1.0-1.2mmThickness:0.25-0.42mmCopperwire:¢1.5-1.7mmCooling

water:≥0.3Mpa 8-10L/minNet

Weight:1300kgsDimension:1350x1300x1700mm 3,Automatic flanging

and seamer machine can height : 70-280mmCan Diameter :

99-180 mmSpeed : 60 cans per minMotor power : 5.5 KWDimension

:7500x1800x2350mmwith PLC control system and servo motor

transmission system, make sure themachine working safely and

stably.Main Parameter :1,This machine is included by the automatic

flanging ring seaming, bottom seaming .The flanging & seaming

machine including machine frame,input conveyor ,can

clampsystem,flanging head, seaming head,lid seperating device and

output convyor.(Includecan turning device),Pneumatic

system,lubricant system and control system. The seamermachine

including machine frame,input conveyor, can sending device,seaming

headlid seperating device,output conveyor and pneumatic

system,control system.2,This machine is taken the PLC automation

controlling system.3, This machine can used for make several sizes

of cans after change moulds.Use thecan clamping device and lid

seperately device make this easier.4,There is a rope conveyor

before flanging which is more convinent for the can goes into

the line after welder.4, Conveyor is take the plastic chain

conveyor which can avoid the damage for can body.5, No cluth

at can seaming head. Which assure the seamer more use

life.6,Lubricant is done by PLC automatically. and the frequency

can be setting.7, One air cylinder is isntalled at the flanging and

seamer machine which can make sure themachine working more

stable,accurat and reliable5, Automatic earlug spot welders Company

profile:Jiangxi United Can Equipment Co.,ltd,China,is a company can

provide all the solutions for Tinplate can making, Steel Drum

making project for more than 20 years . Our machines can be used

for food packaging industry,Chemical packaging industry ,Medical

packaging industry etc. Tinplate Can Machines Including

Automatic slitter,Automatic welder,Automatic body flanging

machine,Automatic seamer machines.Automatic press line for top and

bottom making ,Automatic progressive dies. And some other

components, sealing compound which are necessary in metal can

packaging; Steel drum Making machine including, Automatic

uncoiler line,Automatic press for top and bottom

cover, Precurling and lining machine, Dies, Injection hole

dies ,Automatic drum welders, Body flanging machine , Drum body

leakage tester machine,Drum seamers ,Drum washing and printing

lines etc . And we also provide those compounds,Locking

rings,Seals, Copper wires etc. To provide our customer with best

quality machines and good service is our basic principle.We

sincerely invite the friends to visit us .

/* March 10, 2023 17:59:20 */!function(){function

s(e,r){var

a,o={};try{e&&e.split(",").forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

Related products about Automatic Round Can Bottom Ring Sealing Machine Used 1-5L Paint Metal Tin Can Making Machine

-

Waste Tyre Plastic Recycling Machinery Machine Tire Crusher Production Line Rubber Crumb Grinding Machine Equipment Tire Shredder

Waste Tyre Plastic Recycling Machinery Machine Tire Crusher Production Line Rubber Crumb Grinding Machine Equipment Tire Shredder

-

Stretch Plastic Blowing Pet Bottle Making Blow Molding Machine Bottles Stretch Automatic Pet Bottle Blowing Machine

Stretch Plastic Blowing Pet Bottle Making Blow Molding Machine Bottles Stretch Automatic Pet Bottle Blowing Machine

-

Waste Plastic Pet Bottle, Water Bottle Flake, PP/HDPE/LDPE PE Film Jumbo Woven Bags Plastic Crusher Machine, Plastic Crushing Washing Recycling Machine

Waste Plastic Pet Bottle, Water Bottle Flake, PP/HDPE/LDPE PE Film Jumbo Woven Bags Plastic Crusher Machine, Plastic Crushing Washing Recycling Machine

-

Type 2 Wall-Mounted Electric Car Charging Station 7kw /11 Kwelectric Vehicle Charging Station Home Wallbox AC EV Charger Single Phase or 3three Phase

Type 2 Wall-Mounted Electric Car Charging Station 7kw /11 Kwelectric Vehicle Charging Station Home Wallbox AC EV Charger Single Phase or 3three Phase

-

G-View G12W Wholesale Auto Car LED Headlight Bulb High Power H13 H11 9005 H7 H4 Car LED Headlights LED Car Lights

G-View G12W Wholesale Auto Car LED Headlight Bulb High Power H13 H11 9005 H7 H4 Car LED Headlights LED Car Lights

-

New Design Porcelain Round Plates Dinner Set for Wedding and Banquet

New Design Porcelain Round Plates Dinner Set for Wedding and Banquet

-

China 2023 New Design Super Soft 100% Polyester Microfiber Knitted Oversized Decoration Hoodie Blanket

China 2023 New Design Super Soft 100% Polyester Microfiber Knitted Oversized Decoration Hoodie Blanket

-

Handmade Art Creative Materials Thickened White Paper Cup DIY Disposable Handmade Colored Paper Cup

Handmade Art Creative Materials Thickened White Paper Cup DIY Disposable Handmade Colored Paper Cup