20 Years Of Experience. Reasonable Price And Best Service, CE

Certificated Products.7-15 days fast delivery.Advanced

Technology.Fast Delivery. Please contact us for the

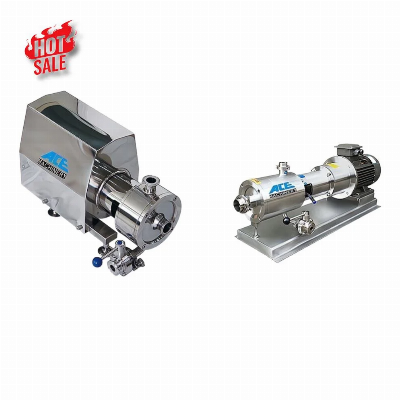

offer.Product DescriptionWelcome to Wenzhou Ace Machines. We are

world leaders in the design and manufacturing of high shear mixers

as well as specializing in Powder/Liquid Mixers, Sanitary Mixers

and Disintegrator / Dissolves. Our technology has many applications

and spans food, pharmaceuticals, cosmetics, chemicals and the lube

oils industries. Description:The emulsification pump (also

called in-line high-shear dispersion mixer) is a high-efficient

fine mixing equipment which integrates mixing, dispersion,

crushing, dissolution, fine, depolymerizing, homogenization and

emulsification, whose working components are mainly stator and

rotator. The rotor rotates rapidly to produce centrifugal force and

hydraulic force and the stator remains stationary. Through the

precise combination of the rotor and the stator, a strong shear

force is generated during high-speed rotation, and the material is

subjected to strong shear, centrifugal extrusion, impact rupture,

liquid friction, and uniform turbulence. Thus, various media such

as immiscible solid phase, liquid phase, and gas phase are

uniformly and finely dispersed and emulsified in an instant. After

a reciprocating cycle, a stable and high-quality product is finally

obtained.Before you place an order, please contact us, we can

custom-make emulsifying homogenizer machine for all your

request.Notice: 1. What kind of material do you want to process?2.

What's the capacity?3. What is it used for? Mixing, dispersing,

shearing or homogenizing?Advantages:1. Suitable for on-line

continuous production of industrialization;2. Narrow size

distribution range, high evenness;3. Energy saving, time saving,

high efficiency;Low noise, smooth operation;4. Eliminate the

wholesale products differences;5. Material 100% by shear;6. With

short distance, low-head transmission function;7. Simple to use,

easy maintenance;8. Can achieve automatic control; Technical

ParametersModelcapacity (T/H)Speed(RPM)out

Pressure(bar)power(KW)ACE-800-1.52900/3400≤2Bar1.5ACE-1000-32900/34002.2ACE-1300-42900/34004.0ACE-1400-52900/34005.5ACE-1650-82900/34007.5ACE-1800-122900/340011ACE-1850-182900/340015ACE-2000-252900/340022ACE-2100-352900/340030ACE-2300-501450/170045ACE-2450-751450/170055*The

above information is for reference only and can be customized

according to customer requirements. *This equipment can be

customized according to customer's materials to meet the needs of

the process, such as requiring greater viscosity, enhanced

homogenization function, heat sensitive materials and other

requirements.Fine Teeth:Ultra-fine dispersion, pulping homogeneous

emulsificationMiddle Teeth:Dispersion, refinement, accelerated

dissolution, emulsificationCoarse teeth:Impact, crushing, shearing,

dissolution, coarse dispersionBatch Mixers Description:high

shear batch mixer doesn't simply mix; it emulsifies, homogenizes,

solubilizes, suspends, disperses and disintegrates solids. Each

mixer, with its precision-engineered rotor/stator workhead, far

outperforms conventional mixers, cutting processing times by up to

90%, improving quality, product consistency and process

efficiency.High Shear Batch Mixers will:Process from 1 to 8000

gallonsEliminate agglomerates and fish eyesCreate stable emulsions

and suspensionsReduce particle sizeRapidly dissolve

solidsAccelerate reactionsThis series of machines are: support

frame, motor, homogenizing head, cylinder, electrical control

systems and control devices. Compact, easy to install, clean and

generous appearance.Homogeneous pinion lift off with pneumatic

type, up off the smooth and flexible. Homogeneous gear shaft and

main parts are all made of stainless steel, wear resistance,

corrosion resistance, excellent quality and long service life,

smooth operation, low noise, any rise in the operation down,

according to material viscosity, speed arbitrary regulation to

prevent the material flying, dispersion impeller for a variety of

materials.Installation method is flexible to adapt to a variety of

venues operation is extremely simple, easy maintenance, strong and

beautiful body. Advanced features, easy to operate, safe facilities

will bring your work pleasant.According to different output

requirements, there are multiple models with different motor powers

as selected. Such as 2.2kw,4kw,5.5kw,7.5kw etcRemark: 1. You can

use your own storage tank, just please tell us your tank size

beforeorder. Or we can provide a storage tank separately.2. If you

have special requirements for the material, stirring paddle,

mixingspeed or dimension, please contact us freely.Laboratory

emulsifier mixer main use:Mix:syrup, shampoo, clean solution, juice

concentrate, yogurt, desserts, mix milk products, printing

ink.Emulsion:medicine lotion, ointment, face mask, emulsion flavor,

oil-water emulsion, emulsion asphalt, resin emulsion, wax em

Related products about Factory Price Multi-Pipe Homogenizing for Continuous Production Process High Shear Powder/Liquid Mixer

-

Waste Tyre Plastic Recycling Machinery Machine Tire Crusher Production Line Rubber Crumb Grinding Machine Equipment Tire Shredder

Waste Tyre Plastic Recycling Machinery Machine Tire Crusher Production Line Rubber Crumb Grinding Machine Equipment Tire Shredder

-

Stretch Plastic Blowing Pet Bottle Making Blow Molding Machine Bottles Stretch Automatic Pet Bottle Blowing Machine

Stretch Plastic Blowing Pet Bottle Making Blow Molding Machine Bottles Stretch Automatic Pet Bottle Blowing Machine

-

Waste Plastic Pet Bottle, Water Bottle Flake, PP/HDPE/LDPE PE Film Jumbo Woven Bags Plastic Crusher Machine, Plastic Crushing Washing Recycling Machine

Waste Plastic Pet Bottle, Water Bottle Flake, PP/HDPE/LDPE PE Film Jumbo Woven Bags Plastic Crusher Machine, Plastic Crushing Washing Recycling Machine

-

Type 2 Wall-Mounted Electric Car Charging Station 7kw /11 Kwelectric Vehicle Charging Station Home Wallbox AC EV Charger Single Phase or 3three Phase

Type 2 Wall-Mounted Electric Car Charging Station 7kw /11 Kwelectric Vehicle Charging Station Home Wallbox AC EV Charger Single Phase or 3three Phase

-

G-View G12W Wholesale Auto Car LED Headlight Bulb High Power H13 H11 9005 H7 H4 Car LED Headlights LED Car Lights

G-View G12W Wholesale Auto Car LED Headlight Bulb High Power H13 H11 9005 H7 H4 Car LED Headlights LED Car Lights

-

New Design Porcelain Round Plates Dinner Set for Wedding and Banquet

New Design Porcelain Round Plates Dinner Set for Wedding and Banquet

-

China 2023 New Design Super Soft 100% Polyester Microfiber Knitted Oversized Decoration Hoodie Blanket

China 2023 New Design Super Soft 100% Polyester Microfiber Knitted Oversized Decoration Hoodie Blanket

-

Handmade Art Creative Materials Thickened White Paper Cup DIY Disposable Handmade Colored Paper Cup

Handmade Art Creative Materials Thickened White Paper Cup DIY Disposable Handmade Colored Paper Cup