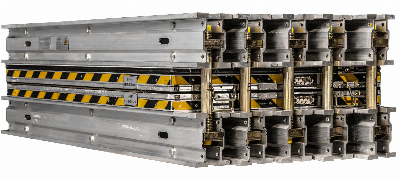

Steelcord Fabric Conveyor Belt Vulcanizing Machine Conveyor Hot

Splice Machine For Conveyor Belts Application of rubber belt

vulcanizer : 1. Steel Cord Belt Intermediate Rubber

is an uncured rubber for hot vulcanized belt splicing. 2. It

is designed to use as an inter-core cord rubber replacement

material in splicing steel cord conveyor belts or a tie gum in

fabric belts.3. The material is designed to bond to cured intercore

rubber and wire cords in all standard grade steel cord

conveyor belts, as well as fabric belt cured skim rubber and

general bond improvement material for general grade fabric conveyor

belts.The ZLJ sectional has uniform pressure bag and aluminum/steel

bolt and high grade aluminum platens and beams with

restraining system set as standard. Such belt splicing system

designed to be portable and easy to set-up and remove from the

site.We can manufacture to all sizes and pressure up to 200 psi

required for different fabric belts and steelcord belts.Technical

Parameters:* Vulcanizing temperature: 145ºC (adjustable 0~200ºC)*

Temperature-rising time (from normal temp to vulcanizing temp):≤50

mins(around 25~30 mins normally)* Improved cooling system: using

pressure pump for cooling:only 5mins (cooling from 145 to 75

degrees)* Belt width: from 650mm to 3000mm 200PSI Almex alike

Uniform Pressure Bag for Conveyor Belt Press* Degree of the heating

platen:22 °/17 °/ 20 ° (rectangle and other degree is optional)*

Waterbag/ air pressure Press for 100PSI, 200PSI etc.* Surface

pressure for textile and steel cord belts, Up to 1.8Mpa.* 100

p.s.i. (7 kg/cm sq.) units suitable for splicing fabric ply

belting* 200 p.s.i. (14 kg/cm sq.) units suitable for splicing

steel cord conveyor belting* Customization/OEM:Different heating

platen size and combination The dimension and shape of

the machine can be customized by your requirements.ALMEX STYLE

design availableModelBelt width(mm)Total Power(kw)Dimensions(L*W*H

mm)Net Weight(kg)Max weight of singleComponent after

separation(kg)ZLJ-650*8306509.51370*830*63043045ZLJ-650*100010.81370*1000*63050066ZLJ-800*83080011.21520*830*63053570ZLJ-800*100013.51520*1000*63057579ZLJ-1000*830100014.11720*830*63059582ZLJ-1000*100015.71720*1000*63062095ZLJ-1600*830160021.52320*830*8001270120ZLJ-1600*100022.32320*1000*8001460146ZLJ-2000*830200027.22720*830*9501760154ZLJ-2000*100030.02720*1000*9501860182OUR

PORDUCTSTANDARD EXPORT PACKAGECompany InformationQingdao Antai

Mining Equipment Co., Ltd. is a manufacturer and international

supplier of compounts for conveyor belt and wear protection

technology and provides worldwide services for conveyor belt

systems.Our products mainly including special Cold Vulcanized

Adhesive and Solvent,Hot Splicing Jointing Materials ,Pully lagging

Materials ,Rubber Skrit, Impact Device (impact bar/impact bed ),

UHMW-PE Rubber,Vulcanized Machine/Press,Conveyor Pully

Rollers&Idler,Conveyor Belt Cleaner and Special Tools.Antai

products have been exported in Europe, Southeast Asia, the Middle

East and North America, and occupied a place in intensely

competitive global market. The products include all aspects of

stuff related on conveyor belt splicing and vulcanizing.FAQ01) Q:

Normal delivery time?A: We have table produce line, hot sale

products normally HAVE STOCK. If customized, need about 15 working

days02) Q: Will you test the machine before shipping?A: Yes, each

machine, we will install and test before shipping. And testing

pressure is higher than working pressure.03) Q: Can you print our

logo or without any logo?A: It's no problem OEM. Before order,

please send us the clear document of your logo, also the

authorization paper to allow us to print your logo. /* March

10, 2023 17:59:20 */!function(){function s(e,r){var

a,o={};try{e&&e.split(",").forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

Related products about Steelcord Fabric Conveyor Belt Vulcanizing Machine Conveyor Hot Splice Machine for Conveyor Belts

-

Waste Tyre Plastic Recycling Machinery Machine Tire Crusher Production Line Rubber Crumb Grinding Machine Equipment Tire Shredder

Waste Tyre Plastic Recycling Machinery Machine Tire Crusher Production Line Rubber Crumb Grinding Machine Equipment Tire Shredder

-

Stretch Plastic Blowing Pet Bottle Making Blow Molding Machine Bottles Stretch Automatic Pet Bottle Blowing Machine

Stretch Plastic Blowing Pet Bottle Making Blow Molding Machine Bottles Stretch Automatic Pet Bottle Blowing Machine

-

Waste Plastic Pet Bottle, Water Bottle Flake, PP/HDPE/LDPE PE Film Jumbo Woven Bags Plastic Crusher Machine, Plastic Crushing Washing Recycling Machine

Waste Plastic Pet Bottle, Water Bottle Flake, PP/HDPE/LDPE PE Film Jumbo Woven Bags Plastic Crusher Machine, Plastic Crushing Washing Recycling Machine

-

Type 2 Wall-Mounted Electric Car Charging Station 7kw /11 Kwelectric Vehicle Charging Station Home Wallbox AC EV Charger Single Phase or 3three Phase

Type 2 Wall-Mounted Electric Car Charging Station 7kw /11 Kwelectric Vehicle Charging Station Home Wallbox AC EV Charger Single Phase or 3three Phase

-

G-View G12W Wholesale Auto Car LED Headlight Bulb High Power H13 H11 9005 H7 H4 Car LED Headlights LED Car Lights

G-View G12W Wholesale Auto Car LED Headlight Bulb High Power H13 H11 9005 H7 H4 Car LED Headlights LED Car Lights

-

New Design Porcelain Round Plates Dinner Set for Wedding and Banquet

New Design Porcelain Round Plates Dinner Set for Wedding and Banquet

-

China 2023 New Design Super Soft 100% Polyester Microfiber Knitted Oversized Decoration Hoodie Blanket

China 2023 New Design Super Soft 100% Polyester Microfiber Knitted Oversized Decoration Hoodie Blanket

-

Handmade Art Creative Materials Thickened White Paper Cup DIY Disposable Handmade Colored Paper Cup

Handmade Art Creative Materials Thickened White Paper Cup DIY Disposable Handmade Colored Paper Cup