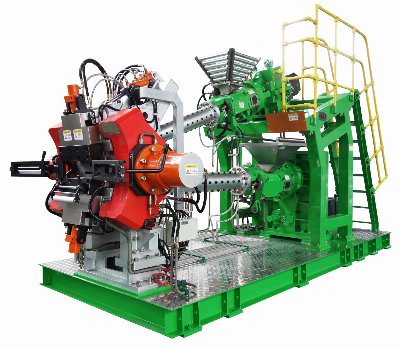

Product DescriptionThe machine is used for the extrusion of

half-finished rubber products such as tire tread, inner tube, rim

bancl and rubber tube. Etc. Product

Parameters TypeXJ-65XJ-115BXJ-120XJ-150XJ-200XJ-250Forms of

screw andscrew threadDouble-head equaldepth convergent

typeDouble-head convergent typeDouble-head convergent typeDouble

head unequal-depthDouble-head convergent typeDouble-head convergent

typeScrew diameter65115120150200250Length-diameter ratioof

screw44.84.64.434.354.5Compression

ratio 1.3 1.34 Rotary speed of

screw5.2-525.4-545.6-55.620-2622.4-67.219.7-59.1Motor

power(kw)Electromagnetic speed 7.5kwElectromagnetic speed

22kwElectromagnetic speed 22kwmotor commutator18.3-55kwmotor

commutator 25-75kwmotor commutator 33.3-100kwProduction

capacity(kg50-80100-420100-450700-12001500-22002000-3200Steam

pressure0.2-0.30.4-0.60.2-0.40.60.6-0.80.6-0.8Cooling water

pressure0.2-0.30.2-0.30.2-0.40.2-0.30.2-0.30.2-0.3Weight(kg)1200260030005000800011400

Our AdvantagesOptimized design of screw,barrel,can meet the

requirement of majority users of different designs,different

formulations,different process requiremnts.The feature of thids

machine is based on the original extruder through

improvement,innovation,highlighting the reliablity,economy and

serviceability.Where contact with plastic material parts are

through the water cycle,and is euipped with a thermostatically

controlled temperature regulation system,choose the appropriate

temperature,which can effectively ensure the quality of extrusion

stability of various compounds.Digital speed control

system,accurate and reliable maintenance exemption.Flexible design

system,in the shortest time to meet the specific design

requirements of customers.With a different head,can achieve

feeding,squeenze film,squeeze tubes,squeeze profiles and other

purpose.Company Profile Qingdao MaoYuanFeng Machinery is

a dedicated company to provide high quality rubber machinery

to worldwide customers.Our solutions:Tire plant solutionTube plant

solutionConveyor belt plant solutionRubber mat plant solutionWaste

tire recycling plant solutionReclaimed rubber plant solutionRubber

product plant solutionWe are manufacturer and dealer of various

kind of rubber machines including rubber processing machines,

rubber product making machines.Our products:Tire making

machines:Rubber anbury mixer, internal mixer, dispersion kneader,

two roll mill, TSR, batch off machine, extruder, calender, building

machine, curing press machine.Conveyor belt making

machines:Vulcanizing press.Rubber mat making machinesInner tube

making machines After Sales ServiceGlobal headquarter:

Qingdao, ChinaBranches: Thailand, Sri Lanka.ServicePlant

engineering -

We provide FREE layout design for new plant.Supplier

Integrity -

24/7 working machines, extremely reliable.Plant Installation

Support -

Installation&commissioning service.Spare

Parts -

Long lasting parts are manufactured by us, always

available.Maintenance/Optimization -

Overseas engineers

available.Training -

We provide FREE training for new plant.Raw

Materials -

Raw material support exported from China.You May Like

FAQ 1. Q: How to guarantee

the quality of outsourcing parts?

A: First choice more than 2 suppler by tender, There are

strict system and process for inspecting outsourcing parts. And

there are outsourcing inspectors, after inspection, qualified

goods, labeling and storage. Not qualified,

return.2. Q: Which brand

of electric part? A: Use world

famous brands, Siemens, Omron, Toshiba, ABBCustomer can specify the

brand.3. Q: Which

PLC: A: Siemens, Omron,

Mitsubishi4. Q:How to control

the quality? A: There

are inspectors for inspecting equipment quality and performance,

after a ssembly, machine run continuously for at least 12 hours at

one time, Total running time should be not less than 48 hours.About

installation1.

Q: When the guide engineer arrive at customer's factory?

A: If need installation on

site, engineer will arrive at factory within one week after machine

arrived at factory.About after-sales

service1. Q: What is

the warranty time? A:

2 years after machine arrived at

factory2. Q: How to

solve the problem?

A: Within one hour after getting customer' problem,

inform the solution way, there are three ways for different

conditions. 1, Which can be solved by phone or Email, it will be

solved in two hours. 2. Which can be solved by Remote Control, it

will be solved within four hours(machine is equipped by Remote

Network Control Problem). 3. Which need solve it on site, engineer

arrive at factory within one week(in the two years warranty date,

engineer has the visa any time of the country where the

machine.Foreign Customers Visit Factory:Will GaoSales

managerQingdao Maoyuanfeng Industry & Trade Co.,L

Related products about Rubber Cold Feed Vacuum Extruder, Rubber Extrusion Microwave Continous Vulcanization Line

-

Waste Tyre Plastic Recycling Machinery Machine Tire Crusher Production Line Rubber Crumb Grinding Machine Equipment Tire Shredder

Waste Tyre Plastic Recycling Machinery Machine Tire Crusher Production Line Rubber Crumb Grinding Machine Equipment Tire Shredder

-

Stretch Plastic Blowing Pet Bottle Making Blow Molding Machine Bottles Stretch Automatic Pet Bottle Blowing Machine

Stretch Plastic Blowing Pet Bottle Making Blow Molding Machine Bottles Stretch Automatic Pet Bottle Blowing Machine

-

Waste Plastic Pet Bottle, Water Bottle Flake, PP/HDPE/LDPE PE Film Jumbo Woven Bags Plastic Crusher Machine, Plastic Crushing Washing Recycling Machine

Waste Plastic Pet Bottle, Water Bottle Flake, PP/HDPE/LDPE PE Film Jumbo Woven Bags Plastic Crusher Machine, Plastic Crushing Washing Recycling Machine

-

Type 2 Wall-Mounted Electric Car Charging Station 7kw /11 Kwelectric Vehicle Charging Station Home Wallbox AC EV Charger Single Phase or 3three Phase

Type 2 Wall-Mounted Electric Car Charging Station 7kw /11 Kwelectric Vehicle Charging Station Home Wallbox AC EV Charger Single Phase or 3three Phase

-

G-View G12W Wholesale Auto Car LED Headlight Bulb High Power H13 H11 9005 H7 H4 Car LED Headlights LED Car Lights

G-View G12W Wholesale Auto Car LED Headlight Bulb High Power H13 H11 9005 H7 H4 Car LED Headlights LED Car Lights

-

New Design Porcelain Round Plates Dinner Set for Wedding and Banquet

New Design Porcelain Round Plates Dinner Set for Wedding and Banquet

-

China 2023 New Design Super Soft 100% Polyester Microfiber Knitted Oversized Decoration Hoodie Blanket

China 2023 New Design Super Soft 100% Polyester Microfiber Knitted Oversized Decoration Hoodie Blanket

-

Handmade Art Creative Materials Thickened White Paper Cup DIY Disposable Handmade Colored Paper Cup

Handmade Art Creative Materials Thickened White Paper Cup DIY Disposable Handmade Colored Paper Cup