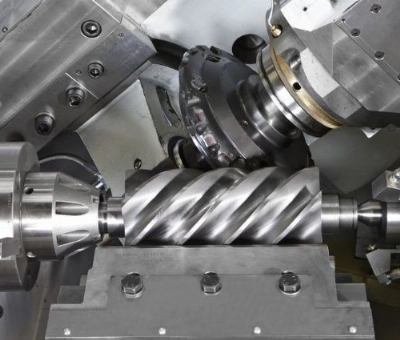

screw milling machine screw milling

machine milling machine special screw

milling machine Cangzhou Kangnuo CNC Machine Tool

Manufacturing Co., Ltd. is located in Botou CNC machine tool

Industrial Park, Hebei Province, the company is located only three

kilometers away from the Nanpi exit of Beijing-Shanghai high-way,

the traffic is very convenient. The company set r & D,

design, production, sales, service in one, not only has a

high-quality staff, but also has a strong product research and

development team, after r & D improvement, our company now has a

series of special CNC machine tools for processing spiral

workpiece.Machine stable performance, high technology content, and

a number of well-known enterprises to maintain long-term

cooperation. Introduction to machine toolsLXK350 type

(external type) CNC screw milling machine is our company's own

research and development of a series of screw processing machine

bed in the leading variety, the product is designed for the

processing of equal lead, variable lead, gradual lead, equal groove

depth, variable groove depth and other special-purpose screw

machine. LXK350 CNC screw milling machine has the following

characteristics: 1, the overall bed design, four guide rail layout,

guide rail surface high-frequency quenching, good rigidity, high

precision. 2, the milling head adopts high power frequency

conversion motor, which can make the milling cutter realize

stepless variable speed and wide speed range. The milling head can

be manually adjusted according to the requirements of the

workpiece. The milling head can go up and down. 3, X axis and Z

axis reciprocating motion using ball screw to achieve high

repeatable positioning accuracy. 4, C axis drive for worm gear and

worm structure, smooth transmission, accurate indexing. 5, the

saddle is dovetail guide rail, high position accuracy, good fast

speed. 6, the spindle bearing is lubricated by oil, low temperature

rise, high durability, and no daily lubrication maintenance. 7, the

machine tail seat is mechanical, flexible and reliable. 8, the

machine is equipped with a wide range of control system. 9, the

machine is equipped with chip discharging machine, the iron filings

generated in the milling process directly into the chip discharging

machine, to ensure the clean working environment. 10. The

electrical components in the machine tool electrical control

cabinet are delixi brand.Bed widthmm800The length of the lathe

bedmm7700Bed guide rail Mountain track + horizontal

trackMaximum workpiece lengthmm6000maximum machining

lengthmm5800Maximum milling diametermmΦ350Center height of machine

tool Center height of machine tool mm500Chuck

specification K11-400CMilling head motor powerKw11

(frequency)Mill head transmission ratio 1:3.3Milling cutter

speed rating r/min400Spindle mounting taper of

milling head 7:24(Φ69.85)Milling head down

adjustment range Milling head down adjustment

range mm-5~+10Milling head adjustable

Angle degree±30C-axis servo motor torque N.m22C shaft

speed r/min0-5C axis drive form Worm gear and wormC

axis transmission ratio 1:300C axis positioning

accuracy second of arc10X axis servo motor torqueN.m15X

axis drive form Ball screw and synchronous

wheel X axis guide rail pair type 55°X axis ball

screw specifications 4005X axis positioning

accuracy mm0.02FAQ:Q1, How do I send my query?You

can contact us via email, phone, instant messaging (WhatsApp,

wechat, Skype). Q2,If you don't know which model is suitable

for your company, please tell us your requirements for the

equipment, or you can send us the product drawings, and our

engineers can help you choose the most suitable model for

you. Q3,delivery timeThe project will be completed within 20

days after receiving the deposit. Please communicate with the sales

staff about the specific construction period. Q4,Payment

Terms30% by T/T as down payment, balance 70% by T/T before

delivery. If others payment terms, we can discuss.Welcome to

inquiry sales.Q5,Can your engineers come to help us install and

debug the machine? Yes, our engineers are available to travel

to your place. Round flight tickets & accommodation will be at your

cost.Q6, If I can't know how to operate. Can your engineer

help me programme well on machine?Sure. You can provide your

detailed sample drawing.engineer can programme well on machine. Or

in some machines, we will put into U-disc of operation video to

help you.Q7,Is there only one model of this device?The standard

processing diameter range of this equipment is 350mm, if you have

other processing range, you can negotiate with the sales

contact. Length range, we can do from 1000mm to 8000mm,

and all are integral cast bed. 8. What control system does the

equipment useOur standard configuration is Guangzhou CNC system,

fanuc and Siemens can also be used, but the price is slightly

different, please contact sales for details.Q9,What control system

does the equipment useOur standard configuration is Guangzhou CNC

system, fanuc

Related products about CNC Screw Milling Machines Oil Press Screw Processing

-

Waste Tyre Plastic Recycling Machinery Machine Tire Crusher Production Line Rubber Crumb Grinding Machine Equipment Tire Shredder

Waste Tyre Plastic Recycling Machinery Machine Tire Crusher Production Line Rubber Crumb Grinding Machine Equipment Tire Shredder

-

Stretch Plastic Blowing Pet Bottle Making Blow Molding Machine Bottles Stretch Automatic Pet Bottle Blowing Machine

Stretch Plastic Blowing Pet Bottle Making Blow Molding Machine Bottles Stretch Automatic Pet Bottle Blowing Machine

-

Waste Plastic Pet Bottle, Water Bottle Flake, PP/HDPE/LDPE PE Film Jumbo Woven Bags Plastic Crusher Machine, Plastic Crushing Washing Recycling Machine

Waste Plastic Pet Bottle, Water Bottle Flake, PP/HDPE/LDPE PE Film Jumbo Woven Bags Plastic Crusher Machine, Plastic Crushing Washing Recycling Machine

-

Type 2 Wall-Mounted Electric Car Charging Station 7kw /11 Kwelectric Vehicle Charging Station Home Wallbox AC EV Charger Single Phase or 3three Phase

Type 2 Wall-Mounted Electric Car Charging Station 7kw /11 Kwelectric Vehicle Charging Station Home Wallbox AC EV Charger Single Phase or 3three Phase

-

G-View G12W Wholesale Auto Car LED Headlight Bulb High Power H13 H11 9005 H7 H4 Car LED Headlights LED Car Lights

G-View G12W Wholesale Auto Car LED Headlight Bulb High Power H13 H11 9005 H7 H4 Car LED Headlights LED Car Lights

-

New Design Porcelain Round Plates Dinner Set for Wedding and Banquet

New Design Porcelain Round Plates Dinner Set for Wedding and Banquet

-

China 2023 New Design Super Soft 100% Polyester Microfiber Knitted Oversized Decoration Hoodie Blanket

China 2023 New Design Super Soft 100% Polyester Microfiber Knitted Oversized Decoration Hoodie Blanket

-

Handmade Art Creative Materials Thickened White Paper Cup DIY Disposable Handmade Colored Paper Cup

Handmade Art Creative Materials Thickened White Paper Cup DIY Disposable Handmade Colored Paper Cup