Steel Shredder Metal Shredder Color Steel Tile ShredderProduct

Description of twin shaft metal shredder :Scrap Metal

Shredder is one metal pre-shredder, processing most heavy waste

metal, such as whole car, aluminum/iron bundles, engine, thick iron

plate, metal drum, motorcycle frame, etc. Kowloon metal shredder is

equipped with planetary reducer of high torque, detachable blades,

Siemens motors and electric cabinet, and other high configurations.

Several such metal shredders have been exported to Poland, Romania,

South Africa, Republic of Korea, Indonesia, Thailand, America,

Mexico, etc. Twin-shaft metal shredder also named shearing

machine, by cutting, tearing and extruting to reduce the materials'

size, widely used in area of waste plastic, waste rubber,

wood, crop straw, automobile recycling…etc, this is a quality and

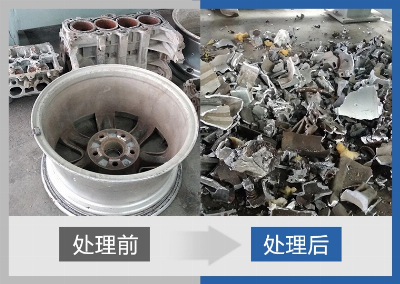

reliable equipment in recycling business.Details photos of metal

shredder machine:Crushing effect:Real picturesTechnical parameters

of metal shredder Model JLSS1200-#13

JLSS1500-#16JLSS2000-#19 Gearbox type #13 planetary

reducer #16 planetary reducer #19 planetary reducer

Main power 45kw*2pcs55kw*2pcs 90kw*2pcs

Materials Light aluminum or iron,engine casing of cars,

motorcycle wheels.Engine casing of trucks,Heavy scraps

metalAluminum bundles,Thick plate of 10mm... Car shell, iron

bundles, hollowed metal ≥10mm, or other heavy-duty metal

products Shredding cavity 1140*1028mm

1415*1250mm 1960*1430mm Rotor speed 6-8rpm

6-8rpm 6-8rpm Blades material 9CrSi, 55SiCr

9CrSi, 55SiCr 9CrSi, 55SiCr Blades diameter

φ530mm φ650mm φ720mm Blades Teeth qty 6 or

8 3 or 6 3 Blades thickness 95mm

112.5mm 160mm Blades Number 12pcs

12pcs 12pcs Working capacity 4-6t/h

10-12t/h 15-25t/h Dimensions

3550x1400x2320mm 4360x2810x2990mm 5370x2956x3120mmOur

advantages of metal shredder: Features of metal shredder

machine : Work methodLow speed and high torque shear crushing,

broken soft and hard material, low noise, low dustDrive

modeElectric motor + gearboxCabinetAutomatic positive

and negative transfer power distribution cabinet, the control

performance is stableOverload protectionWhen equipment overload

automatic stop inversion automatically, return unloading material,

after the completion of the unloading equipment recovery forward,

when the current exceeds the rated 3s stop order - interval 8s

single motor reversal start - interval 8s start- interval 20s

normal work. (90s)Blade material55SiCr(can be customized); 9CrSi

for blade head of detachable bladesShred blade installShred blade

and shaft fixed by hexagonal shape, to guarantee good torque

transferred, easy for disassemble easier for maintenance.Blade

corner installinner hexagon screw fixed, pin fixed

positionShaftHigh strength shaft, made of 40CrSealing methodfour

heavy seal protection design bearing, effective dustproof and

waterproof, prolongs bearing service life, can work normally in

high dust and outdoor environment Feed hoppercan be designed

according to customer's actual situationWallboard standModular

assembly of welding parts is adopted to facilitate disassembly and

maintenanceRunning noise1 meter no-load noise is less than 85db

(A), load noise according to the condition of material are

differentCustomer site:Delivery of double shaft metal

shredder 1.Plastic wraps to protect wood shredder, tire

shredder from dust, moisture and corrosion.2. Wooden case for

compact machine or wearing parts as the outside package. Or

according to the customer requirements.3.Excellant logistic team to

guarantee the shredder machines to be safely shipped to customer

warehouse, no extra fee on export or import on custom After

sale services of metal shredder for sale :1. Pre-sales:

Provide fitted solution and offer to customers, is able to adjust

the layout of complete line to fit customers' working area, also

provide technical support 24 hours service online.2. After

sales:Kowloon skilled technicians are experienced at oversea

installation, therefore they are available to assist with onsite

installation, commissioning & training on request. Layout drawing,

circuit diagram and maintenance manual will be provided together

with our products after sales, so that ensure customers have plenty

of time to get prepared for installation.3. Wearing parts

supportKowloon has widely built extensive cooperation with wearing

parts partner manufacturers more than 14years, has ability to

continuously provide wearing parts and after-sale service to global

market.KOWLOON was established since 1986, located in

Zhengzhou city, which city of industrial hub of China, 30years

experience on manufacturing of:Wood processing machinery: wood

pellet production line, wood shredder, wood drum chipper, wood

sawdust machine, wood powder machine, rotary dryer and air flow

drying machine, wood debarking machine.Waste tire recycling

machinery: tire recycling plant, industrial two shaft shredder,

tire roller mill multi-purpose rasper, rubber granulator, rubber

powde

Related products about Steel Metal Shredder Color Steel Tile Shredder Aluminum Recycling Equipment for Sale

-

Waste Tyre Plastic Recycling Machinery Machine Tire Crusher Production Line Rubber Crumb Grinding Machine Equipment Tire Shredder

Waste Tyre Plastic Recycling Machinery Machine Tire Crusher Production Line Rubber Crumb Grinding Machine Equipment Tire Shredder

-

Stretch Plastic Blowing Pet Bottle Making Blow Molding Machine Bottles Stretch Automatic Pet Bottle Blowing Machine

Stretch Plastic Blowing Pet Bottle Making Blow Molding Machine Bottles Stretch Automatic Pet Bottle Blowing Machine

-

Waste Plastic Pet Bottle, Water Bottle Flake, PP/HDPE/LDPE PE Film Jumbo Woven Bags Plastic Crusher Machine, Plastic Crushing Washing Recycling Machine

Waste Plastic Pet Bottle, Water Bottle Flake, PP/HDPE/LDPE PE Film Jumbo Woven Bags Plastic Crusher Machine, Plastic Crushing Washing Recycling Machine

-

Type 2 Wall-Mounted Electric Car Charging Station 7kw /11 Kwelectric Vehicle Charging Station Home Wallbox AC EV Charger Single Phase or 3three Phase

Type 2 Wall-Mounted Electric Car Charging Station 7kw /11 Kwelectric Vehicle Charging Station Home Wallbox AC EV Charger Single Phase or 3three Phase

-

G-View G12W Wholesale Auto Car LED Headlight Bulb High Power H13 H11 9005 H7 H4 Car LED Headlights LED Car Lights

G-View G12W Wholesale Auto Car LED Headlight Bulb High Power H13 H11 9005 H7 H4 Car LED Headlights LED Car Lights

-

New Design Porcelain Round Plates Dinner Set for Wedding and Banquet

New Design Porcelain Round Plates Dinner Set for Wedding and Banquet

-

China 2023 New Design Super Soft 100% Polyester Microfiber Knitted Oversized Decoration Hoodie Blanket

China 2023 New Design Super Soft 100% Polyester Microfiber Knitted Oversized Decoration Hoodie Blanket

-

Handmade Art Creative Materials Thickened White Paper Cup DIY Disposable Handmade Colored Paper Cup

Handmade Art Creative Materials Thickened White Paper Cup DIY Disposable Handmade Colored Paper Cup