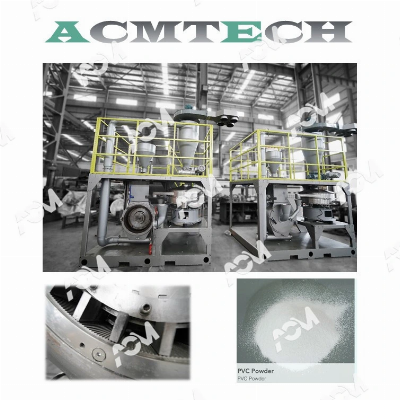

Product DescriptionIn order to meet all kinds of customer's

production demand, ACMTech has been designing and

manufacturing ACM-P series

high-speed plastic pulverizer machine, whose design

and research is based on absorbing and taking advantage

of home and abroad advanced pulverizer machine. It is the

ideal machine for processing and milling thermoplastic materials of

PVC, PE/PP/PS/ABS etc., alsoit is the necessary machine of

recycling the leftover material and scrap during the production.

After the professional plastic manufacturers' provability of the

practice, when we add 20%-30% milled leftover material and scrap in

the formula, the chemical and physical character of finished

product keeps the same as the completely new materials'. So it is

an ideal machine for the plastic manufacturers to save their cost

and solve the overstock of scrap and inferior. This machine also

called mill/Milling machine/Miller machine/Grinding

machine/Grinder/Grinder machine/Grinding

mill/Crusher/Shredder/Milling machine/Roller

mill.APPLICATION:·PVC regrind pipe and profile.·Working in line

with a shredder and granulator to have a balanced and efficient

system to handle in house production wasteMORE DETAILED

PHOTOS:Product ParametersCertificationsPackaging &

ShippingInstallation InstructionsCompany ProfileSuzhou ACMtech

Machinery Co., ltd., is a company, which is specialized on plastic

extrusion and recycling machinery manufacturing and trading. ACM

has top-ranking Research and Development technology system and rich

experienced technician team. The main product scope of ACM is

Extrusion and Recycling. Extrusion contains: PO and PVC PIPE,

PROFILE, SHEET Extrusion Line. Recycling contains: PET, PE, PP,

ABS, PC product washing and recycling. Our vision is to offer you

the best and the most appropriate plastic extrusion and recycling

solution, to offer you the most reliable technically and commercial

service support.Our AdvantagesExihibition:After Sales

Service Technical documentationAll symbols on the equipment

will be in English. We will be responsible for providing the Buyer

with a general layout plan, electrical plan, installation

orientation and manuals, in English.Arrangements for inspection,

installation and testing of the equipmenta. After all of the

equipment is delivered to the customer's factory, the Buyer shall

be responsible for all preparation work, e.g. electricity supply,

water supply, cranes and labor, etc.b. We will prepare visa

applications for their engineers, who will assist in the equipment

installation and testing at the Buyer's factory. c. The

Buyer will buy a round-trip air ticket for the engineer(s) after

the visa application is approved. The Buyer is responsible for all

expenses generated, e.g. visa application fees, meals,

accommodation and an allowance of $80.00 per day for each

engineer.d. The engineer(s) will provide free training for the

operators and maintenance people, in Buyer's factory.e. If the

Buyer does not request commissioning by our engineer(s) within four

months from the date of the bill of lading, it will be accepted

that all the equipment has been successfully tested and approved by

the Buyer.Quantity and quality guaranteea. In cases of quantity

discrepancies or equipment damage, at the destination, the Buyer

will file a claim within 30 days after the arrival of the goods at

its destination. The insurance company and the shipping company

will be responsible for all discrepancies and damage caused by the

shipping company or other transportation companies. b.

Guarantee period and after-sales services: 13 months from the date

of the bill of lading.During this guarantee period, if there is a

quality issue, we will provide spare parts without charge. If

malfunctions are caused by the Buyer's improper operation of

equipment, we will provide the Buyer with spare parts at cost

prices. c. Long-term service:Beyond one year, we will provide

the Buyer with spare parts at reasonable prices and provide

long-term technical guidance./* March 10, 2023 17:59:20

*/!function(){function s(e,r){var

a,o={};try{e&&e.split(",").forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

Related products about Hard/Soft Material PP/EVA/HDPE Pellets Milling Machine/PE PP EVA Pulverizer

-

Waste Tyre Plastic Recycling Machinery Machine Tire Crusher Production Line Rubber Crumb Grinding Machine Equipment Tire Shredder

Waste Tyre Plastic Recycling Machinery Machine Tire Crusher Production Line Rubber Crumb Grinding Machine Equipment Tire Shredder

-

Stretch Plastic Blowing Pet Bottle Making Blow Molding Machine Bottles Stretch Automatic Pet Bottle Blowing Machine

Stretch Plastic Blowing Pet Bottle Making Blow Molding Machine Bottles Stretch Automatic Pet Bottle Blowing Machine

-

Waste Plastic Pet Bottle, Water Bottle Flake, PP/HDPE/LDPE PE Film Jumbo Woven Bags Plastic Crusher Machine, Plastic Crushing Washing Recycling Machine

Waste Plastic Pet Bottle, Water Bottle Flake, PP/HDPE/LDPE PE Film Jumbo Woven Bags Plastic Crusher Machine, Plastic Crushing Washing Recycling Machine

-

Type 2 Wall-Mounted Electric Car Charging Station 7kw /11 Kwelectric Vehicle Charging Station Home Wallbox AC EV Charger Single Phase or 3three Phase

Type 2 Wall-Mounted Electric Car Charging Station 7kw /11 Kwelectric Vehicle Charging Station Home Wallbox AC EV Charger Single Phase or 3three Phase

-

G-View G12W Wholesale Auto Car LED Headlight Bulb High Power H13 H11 9005 H7 H4 Car LED Headlights LED Car Lights

G-View G12W Wholesale Auto Car LED Headlight Bulb High Power H13 H11 9005 H7 H4 Car LED Headlights LED Car Lights

-

New Design Porcelain Round Plates Dinner Set for Wedding and Banquet

New Design Porcelain Round Plates Dinner Set for Wedding and Banquet

-

China 2023 New Design Super Soft 100% Polyester Microfiber Knitted Oversized Decoration Hoodie Blanket

China 2023 New Design Super Soft 100% Polyester Microfiber Knitted Oversized Decoration Hoodie Blanket

-

Handmade Art Creative Materials Thickened White Paper Cup DIY Disposable Handmade Colored Paper Cup

Handmade Art Creative Materials Thickened White Paper Cup DIY Disposable Handmade Colored Paper Cup