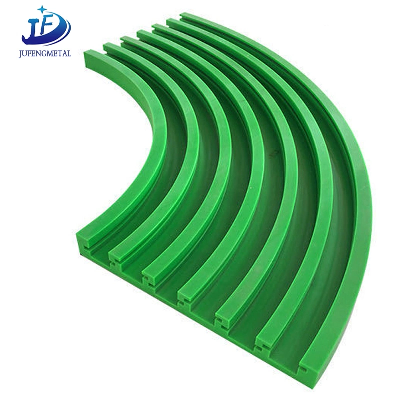

Hot Sale Wear Resistance UHMWPE Plastic Roller Chain

GuidesProduct Description Product rangeProducr design,mold

design, mold making and produce plastic partsProcessing CraftMold

fabrication, Injection

etc;MaterialABS,BMC,SMC,AS,PVC,Nylon(PA),PP,PC,PE,POM,PS,HDPE,TPE,TPU

etcSurface finishPolishing finish,Texture Finish,Glossy Finish

etcColorRAL/PANTONE colorMold StandardDME,LKM,FUTA,HASCO etc.Mould

Baseas per customer's requirementTolerance0.01~0.1mmFile

FormatSolidworks,Pro/Engineer,Auto CAD,PDF,JPGQuality

ControlQuality ControlInspectionIQC, IPQC,FQC,QAApplicationAll

kinds of plastic injection parts being used in a variety of

industrial application Product

features Excellent sliding

properties. High wear resistance.

High impact strength. Very good chemical

and corrosion resistance. Good noise

absorption. Anti-adhesive.

High energy absorption capacity and high stress rates.

Temperature resistance from -200°C to +80°C.

Physiologically safe.Rapid toolingFast and

cost-effective process to create aluminum or steel injection molds

for quick turn injection molding. Ideal for rapid prototyping needs

or validating product concept for production.OvermoldingOvermolding

is a unique injection molding process that combines two or more

components together. It is the best practice for the plastic

manufacturing of multi-color and multi-layers products.Insert

moldingInsert molding is a custom injection molding process that

encapsulates components in a plastic part. It is most commonly used

for prototype injection molding designs with threads and

holes.Liquid Silicone Rubber injection moldingLiquid silicone

rubber (LSR) is a flexible prototype injection molding process that

produces elastic, durable parts. Get custom prototypes and

production parts from 15 days.Company ProfileWe can source and mold

any grade of material from typical commodity grade plastics, to

engineering, functional, and structural grade materials in a

variety of colors and formulations. In addition to injection

molding, we offer many secondary services including sonic

vibration, RF welding, hot stamping, etching, printing, plating,

and packaging. Our manufacturing processes are highly

automated, which allows us to run a precise and efficient

production floor with minimal overhead costs. These

capabilities allow us to provide fast and cost competitive

manufacturing services to our customers without sacrificing

precision and quality.Application Chemical

Engineering: Corrosion and wear resistance mechanical parts.

Thermal power: coal handling, storage of coal,

warehousing chute lining. Coal processing: sieve

plate, filter, U-underground coal chute.

Concrete: cement raw and finished product silo lining.

Grain: food storage or chute lining.

Mining: sieve plate, chute linings, wear anti-bonding

part. Food industry: star-shaped wheel,

transmission timing bottle screw, bearings, guide rollers, guides,

slide blocks, etc. About

UHMWPE: UHMWPE (also known as Ultra High

Molecular Weight Polyethylene) Sheet and Rod products

are manufactured from the semi-crystalline

polyethylene (PE) family. Chinese UHMWPE Sheet and rods'

maximum molecular weight can reach to 5 million

which has a positive impact on material performance

in an abrasive environment.

UHMWPE properties ensure that this plastic material is

very light, extremely tough, chemically resistant

and has excellent wear resistance.

You can look through our website to find your

interest or email your any questions through below

approach! We will reply to you within 12 hours./* March 10, 2023

17:59:20 */!function(){function s(e,r){var

a,o={};try{e&&e.split(",").forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

Related products about Hot Sale Wear Resistance UHMWPE Plastic Roller Chain Guides

-

Waste Tyre Plastic Recycling Machinery Machine Tire Crusher Production Line Rubber Crumb Grinding Machine Equipment Tire Shredder

Waste Tyre Plastic Recycling Machinery Machine Tire Crusher Production Line Rubber Crumb Grinding Machine Equipment Tire Shredder

-

Stretch Plastic Blowing Pet Bottle Making Blow Molding Machine Bottles Stretch Automatic Pet Bottle Blowing Machine

Stretch Plastic Blowing Pet Bottle Making Blow Molding Machine Bottles Stretch Automatic Pet Bottle Blowing Machine

-

Waste Plastic Pet Bottle, Water Bottle Flake, PP/HDPE/LDPE PE Film Jumbo Woven Bags Plastic Crusher Machine, Plastic Crushing Washing Recycling Machine

Waste Plastic Pet Bottle, Water Bottle Flake, PP/HDPE/LDPE PE Film Jumbo Woven Bags Plastic Crusher Machine, Plastic Crushing Washing Recycling Machine

-

Type 2 Wall-Mounted Electric Car Charging Station 7kw /11 Kwelectric Vehicle Charging Station Home Wallbox AC EV Charger Single Phase or 3three Phase

Type 2 Wall-Mounted Electric Car Charging Station 7kw /11 Kwelectric Vehicle Charging Station Home Wallbox AC EV Charger Single Phase or 3three Phase

-

G-View G12W Wholesale Auto Car LED Headlight Bulb High Power H13 H11 9005 H7 H4 Car LED Headlights LED Car Lights

G-View G12W Wholesale Auto Car LED Headlight Bulb High Power H13 H11 9005 H7 H4 Car LED Headlights LED Car Lights

-

New Design Porcelain Round Plates Dinner Set for Wedding and Banquet

New Design Porcelain Round Plates Dinner Set for Wedding and Banquet

-

China 2023 New Design Super Soft 100% Polyester Microfiber Knitted Oversized Decoration Hoodie Blanket

China 2023 New Design Super Soft 100% Polyester Microfiber Knitted Oversized Decoration Hoodie Blanket

-

Handmade Art Creative Materials Thickened White Paper Cup DIY Disposable Handmade Colored Paper Cup

Handmade Art Creative Materials Thickened White Paper Cup DIY Disposable Handmade Colored Paper Cup