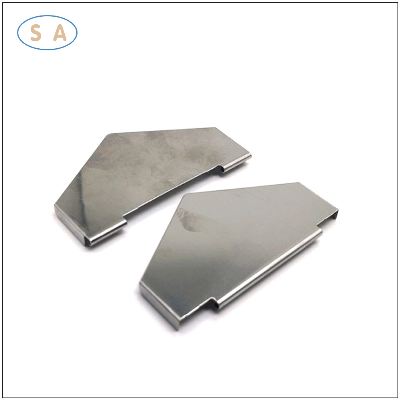

OEM Aluminum Alloy/Steel Stamping Bending Construction

Hardware Product Description QuotationAccording to your

drawing(size, material, thickness, processing content, and required

technology, etc)MaterialCarbon steel, SPCC, SGCC, Stainless steel,

Aluminum, Brass, Copper, etc.ProcessingLaser Cutting, Precision

Stamping, Bending, CNC Punching, Threading, Riveting, Drilling,

Welding etcSurface TreatmentBrushing, Polishing, Anodizing, Powder

Coating, Plating, Silkscreen printing, Sandblast,

etcTolerance+/-0.2mm, 100% QC quality inspection before delivery,

can provide quality inspection formLogoSilk print, Laser

marking.SizeAccept custom size.ColorWhite, black,silver, red, grey,

Pantone and RAL, etcDrawing formatDWG, DXF, STEP, IGS, 3DS, STL,

SKP, AI,PDF, JPG, Draft.Sample lead timeNo surface treatment,

1-3 workdays. Require surface treatment, 3-5 workdays.Pricing

TermEXW, FOB, CIF, etcPayment termSample: 100% payment before

production Mass production: (50% in advance as deposit,

balance before

delivery)CertificateISO9001:2015/SGS/TUV/RoHSPackingBy carton or as

your request Our manufacturing

capability: ·Punch range from 16T

to 500T

·Hydraulic plate shears

·Bending machine

·Hydraulic

draw-bench

·Blanking, piercing, bending, forming,

and deep drawn 1. ISO9001-2008. 2. Has

advanced euipment and over 15 years experience. 3.

Price: Competetive price, Precision made. Experience & Reasonable

QC that you can reply on. 4. Process: Precision made.

Experience & Reasonable QC that you can reply on Each part

would be given 100% test and tryout before

shipment. 5. Adequate supply capacity. Punctual

delivery

time.MaterialCarbon steel, stainless steel, brass,

zinc/aluminum alloy etcSurface

treatmentGalvanized, zinc plating, powder coating,

electroplate.ApplicationConstruction parts, furniture hardware,

electronic hardware, machinery parts, art-wareTooling roomYes, mold

was made by ourselves.Machinery capabilityHydraulic press machine,

cold chamber machine, machining center, the machines for bending,

grinding, milling, drilling, welding, polishing, shot blasting

machine.PackingFilm/Carton/Plywood box, or according to customer's

requirement.OEM/ODMAcceptableQ: Why choose Shengao product?A: We

shengao have our own plant Weifang Shengao machinery Co., Ltd,

therefore, we cansurely promise the quality of every product and

provide you comparable price.Q: Do you provide OEM Service?A: Yes,

we provide OEM Service.Q: Do you provide customized Sheet Metal

Stamping/Stamped Parts/Punching Parts?A: Yes. Customers give us

drawings and specifications, and we will manufact accordingly.Q:

What is your payment term?A: We provide kinds of payment terms such

as L/C, T/T, Paypal, Escrow, etc. Shipping way:1)

0-100kg: express&air freight priority,2) >100kg: sea freight

priority,3) As per customized specificationsIn order to ensure the

quality of the orders,our independent QC members to carry out

strict inspection at each stage:(1)Incoming material

inspection(2)Inspection of work-in-progress(3)Finished product

inspection(4)Random warehouse inspectionsAll of our operations are

strictly compliant with ISO 9001: 2015 guidelines We own automated

casting lines, CNC machining, CMM inspection, spectrometers and MT

testing equipment, X-ray. To benefit from our strong OEM/ODM

capabilities and considerate services, contact us today. We will

sincerely create and share success with all clients.If there is

anything we can help you, welcome to contact us anytime!/* March

10, 2023 17:59:20 */!function(){function s(e,r){var

a,o={};try{e&&e.split(",").forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

Related products about OEM Aluminum Alloy/Steel Stamping Bending Construction Hardware

-

Waste Tyre Plastic Recycling Machinery Machine Tire Crusher Production Line Rubber Crumb Grinding Machine Equipment Tire Shredder

Waste Tyre Plastic Recycling Machinery Machine Tire Crusher Production Line Rubber Crumb Grinding Machine Equipment Tire Shredder

-

Stretch Plastic Blowing Pet Bottle Making Blow Molding Machine Bottles Stretch Automatic Pet Bottle Blowing Machine

Stretch Plastic Blowing Pet Bottle Making Blow Molding Machine Bottles Stretch Automatic Pet Bottle Blowing Machine

-

Waste Plastic Pet Bottle, Water Bottle Flake, PP/HDPE/LDPE PE Film Jumbo Woven Bags Plastic Crusher Machine, Plastic Crushing Washing Recycling Machine

Waste Plastic Pet Bottle, Water Bottle Flake, PP/HDPE/LDPE PE Film Jumbo Woven Bags Plastic Crusher Machine, Plastic Crushing Washing Recycling Machine

-

Type 2 Wall-Mounted Electric Car Charging Station 7kw /11 Kwelectric Vehicle Charging Station Home Wallbox AC EV Charger Single Phase or 3three Phase

Type 2 Wall-Mounted Electric Car Charging Station 7kw /11 Kwelectric Vehicle Charging Station Home Wallbox AC EV Charger Single Phase or 3three Phase

-

G-View G12W Wholesale Auto Car LED Headlight Bulb High Power H13 H11 9005 H7 H4 Car LED Headlights LED Car Lights

G-View G12W Wholesale Auto Car LED Headlight Bulb High Power H13 H11 9005 H7 H4 Car LED Headlights LED Car Lights

-

New Design Porcelain Round Plates Dinner Set for Wedding and Banquet

New Design Porcelain Round Plates Dinner Set for Wedding and Banquet

-

China 2023 New Design Super Soft 100% Polyester Microfiber Knitted Oversized Decoration Hoodie Blanket

China 2023 New Design Super Soft 100% Polyester Microfiber Knitted Oversized Decoration Hoodie Blanket

-

Handmade Art Creative Materials Thickened White Paper Cup DIY Disposable Handmade Colored Paper Cup

Handmade Art Creative Materials Thickened White Paper Cup DIY Disposable Handmade Colored Paper Cup