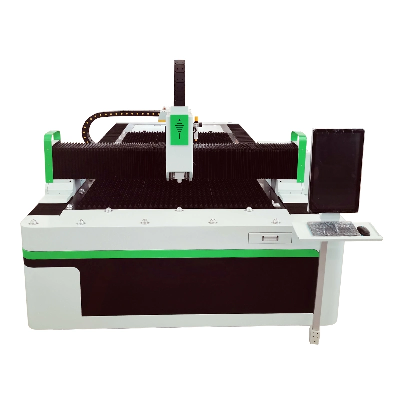

Product DescriptionModel3015FLaser wave

length1064nmTransmission systemGear + rails(we have standard brand,

we can also produce as your requirements)X.Y axis location

accuracy±0.01mmX.Y axis repeat location accuracy±0.01mmX.Y axis max

moving speed120m/minApplication Materialplate /sheet metalwork;Iron

/ Carbon Steel / Stainless Steel / Aluminum/ Copper and all kinds

metalDetailed PhotosHow Does A Fiber Laser Cutting Machine Work?The

laser emitted by the fiber laser generator is focused by the

optical path system into a fiber laser beam of high power density.

The fiber laser beam is irradiated onto the surface of the

workpiece to bring the workpiece to a melting point or boiling

point, while the high-pressure gas coaxial with the fiber laser

beam blows away the molten or vaporized material. As the fiber

laser beam moves relative to the workpiece, the material is slit

finally, thereby achieving the purpose of cutting.Applied

materials:The fiber laser machine is mainly used for cutting

stainless steel, carbon steel, electrical steel, galvanized steel,

aluminum zinc plate, aluminum, aluminum alloy, titanium alloy,

copper, brass, iron and other metal materials. Applied

Industries:The fiber laser machine is applied in sheet metal

cutting, aviation, spaceflight, electronics, electrical appliances,

subway parts, automobile, machinery, precision components, ships,

metallurgical equipment, elevator, household appliances, gifts,

arts and crafts, tool processing, adornment, advertising, metal

foreign processing, various metal cutting industries.Fiber Laser

Cutting Machine Features:1. Excellent beam quality: Smaller focus

diameter and high work efficiency, high quality.2. High cutting

speed: The laser cutting speed is more than 40m/min.3. Stable

running: Adopting the top brand fiber laser source, stable

performance, key parts can reach 100,000 hours.4. High efficiency

for photoelectric conversion: Compare with CO2 laser cutting

machine, fiber laser cutting machine has three times photoelectric

conversion efficiency.5. Low cost, Low maintenance: Save energy and

protect environment.6. Easy operations: fiber line transmission, no

adjustment of optical path.7. Super flexible optical effects:

Compact design, easy to flexible manufacturing

requirements. Stable Lathe* Plate welding bed, more stable and

durable.* After annealing treatment, the bed ensures the smooth

operation of the cutting machine.Laser Source* High power, from

1000W to 15000W. * Raycus/MAX/IPG, multiple choice different

brands, different laser power are available. * The higher

power, the thicker cutting thickness.Automatic Focusing Laser Head*

Raytools, Au3tech, WSX can be selected, high speed and stable.

* Laser head follow-up funtion Follow the change of the

height of the board.Servo Motor And Drives You can choose

YASKAWA/FUJI.* Accuracy: realizes closed-loop control of position,

speed and torque; overcomes the problem of stepping motor out of

step; * Rotating speed: high speed performance, general

rated speed can reach 2000~3000 rpm.Cypcut Plane Control

System(2000) * CypCut plane cutting software is a set of

software specially developed for the deep customization of the

laser cuttingindustry. Easy to use, rich in functions, suitable for

various processing occasions.* Edge finding aid Dual-drive

deviation self-correcting two-stage capacitive edge seeking.Sample

DisplayPackaging & ShippingLaser equipment is a relatively precise

machine, beware of bump and friction in the process of

transportation, which requires us to do a good job of packaging

before transportation. Morita, as a professional manufacturer of

laser equipment in China, has a lot of experience in packaging all

kinds of laser equipment.1. Wipe the machine, the machine is wiped

clean, not only for beautiful, more important is to prevent the

machine attached to the machine is in the process of transport of

particles cut surface, damage the paint. 2. We will use

stretch film to winding machine,let the machine with a layer of

protective film, this is to let the machine during transport to

prevent damage in the process offriction. 3. We'll let the

machine then wrapped with thick foam board, this can prevent

machine in the process of transportation by knock against,

impact. 4. Installation of wooden boxes, thick wooden cases

like a layer of armor, can protect the machine to agreat

extent. 5. In front of the cover in the middle of the machine

and the cases filled with rubber cushion, this will prevent

collision between machines and wooden case, can also further to

package the machine. From CustomersCompany Profile· With 15

years experience, MORITA LASER has established a complete system

for the development and manufacture of laser marking, cutting,

engraving and welding technologies.· Main products: fiber laser

cutting machine, fiber laser marking machine, crystal engraving

machine, CO2 laser marking machine, UV laser marking machine, laser

engraving machine, laser cutting machine, CNC en

Related products about Standard Export Packing 3015 Products 1000W 1500W 2000W 3000W CNC Sheet Metal Fiber Laser Cutting Machine for Manufacture Exhibition

-

Waste Tyre Plastic Recycling Machinery Machine Tire Crusher Production Line Rubber Crumb Grinding Machine Equipment Tire Shredder

Waste Tyre Plastic Recycling Machinery Machine Tire Crusher Production Line Rubber Crumb Grinding Machine Equipment Tire Shredder

-

Stretch Plastic Blowing Pet Bottle Making Blow Molding Machine Bottles Stretch Automatic Pet Bottle Blowing Machine

Stretch Plastic Blowing Pet Bottle Making Blow Molding Machine Bottles Stretch Automatic Pet Bottle Blowing Machine

-

Waste Plastic Pet Bottle, Water Bottle Flake, PP/HDPE/LDPE PE Film Jumbo Woven Bags Plastic Crusher Machine, Plastic Crushing Washing Recycling Machine

Waste Plastic Pet Bottle, Water Bottle Flake, PP/HDPE/LDPE PE Film Jumbo Woven Bags Plastic Crusher Machine, Plastic Crushing Washing Recycling Machine

-

Type 2 Wall-Mounted Electric Car Charging Station 7kw /11 Kwelectric Vehicle Charging Station Home Wallbox AC EV Charger Single Phase or 3three Phase

Type 2 Wall-Mounted Electric Car Charging Station 7kw /11 Kwelectric Vehicle Charging Station Home Wallbox AC EV Charger Single Phase or 3three Phase

-

G-View G12W Wholesale Auto Car LED Headlight Bulb High Power H13 H11 9005 H7 H4 Car LED Headlights LED Car Lights

G-View G12W Wholesale Auto Car LED Headlight Bulb High Power H13 H11 9005 H7 H4 Car LED Headlights LED Car Lights

-

New Design Porcelain Round Plates Dinner Set for Wedding and Banquet

New Design Porcelain Round Plates Dinner Set for Wedding and Banquet

-

China 2023 New Design Super Soft 100% Polyester Microfiber Knitted Oversized Decoration Hoodie Blanket

China 2023 New Design Super Soft 100% Polyester Microfiber Knitted Oversized Decoration Hoodie Blanket

-

Handmade Art Creative Materials Thickened White Paper Cup DIY Disposable Handmade Colored Paper Cup

Handmade Art Creative Materials Thickened White Paper Cup DIY Disposable Handmade Colored Paper Cup