Product DescriptionZSFQ-C Automatic High-speed Slitting and

Rewinding Machine for

Adhesive Label and Film ApplicationMachine

suitable many kinds of jumbo roll materials, such as adhesive

stickers/ PVC /PET/Release paper/breathable film/Pearlized

BOPP.Advantage1.The machine adopts three servo motors, synchronous

control, automatic tension,central surface rewinding.2.The machine

uses frequency converter adjust speed motor, it can keep stable

operation when speedup.3.It adopts PLC autometer count, automatic

alarm; The rewinding adopts A,B slip shaft structures (Air shaft

can be chosen).4.The unwinding adopts ultrasonic correcting edge

position.5.Circular /flat knife cut the materials. The waste edge

uses high pressure air blower to discharge. 6.Hydraulic shaft-less

loading structure.7.Loading rock,material unloading

convenience. Model ZSFQ-1300C ZSFQ-1600C ZSFQ-1800C Max.Width

of unwinding roll 1300 mm 1600 mm 1800 mm Max. Diameter of

unwinding roll 800 mm(1400 mm) 800 mm(1400 mm) 800 mm(1400 mm)

Min.Width of slitting 30mm 30mm 30mm Max. Diameter

of rewinding roll 600 mm 600 mm 600 mm speed

80-400 m/min 80-400 m/min 80-400 m/min Total Power 15kw 18kw

20kw Weight 3500 kg 4000 kg 4300 kg Dimension(L*W*H) 2050x3000x1720

mm 2050x3300x1720 mm 2050x3500x1720 mm Roll To Roll

ProcessLoading jumbo rolls in our machine, setting up the knife

position based on slitting width you want to get. Then you will get

several finished roll slitting and rewinding with different

sizes or same sizes then move it out for production

after. Detailed Photos1. About unwinding,According to the

size of the customer's material, choose

the conjoint unwinding rack or

separate unwinding rackconjoint unwinding rackseparate unwinding rack2.

Magnetic powder brake control tension. Make the material

surface more flat, no wrinkles. Adopt edge

position correction device, make cut more smoothly, more

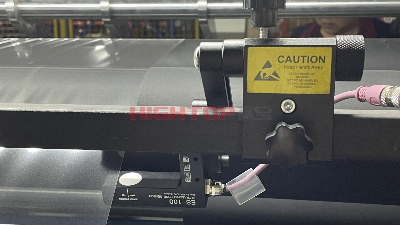

neatly cut.Magnetic powder brakeEdge Position Correction Sensor3.

Because the curved roll has a certain arc, when the material

rotates through the curved roll, the material will be stretched in

the longitudinal direction to achieve the effect of stretching the

material, to eliminate the wrinkles in the process of the

material and prevent the interleaving that may occur during the

material cutting process Different materials

need different types of knives for cutting, but film materials

mostly use flat knives for cutting, if you do not know which knife

is better, welcome to contact usCurved roll (Stretch out

material)Flat knife4. PLC adopts German Siemens technology to

accurately control the system. The machine also

has a waste edge discharge device, which can deal with the problems

left over from the waste edge.Siemens PLCWaste edge discharge5.

About rewinding, the rewinding adopts differential

rewinding shafts, which makes the winding tension control more

flexible and the material rewinding performance better.

The unloading adopts F-type unloading rack, which makes the

unloading more easy and convenient.differential rewinding shaft*

2pcsF type unloading device Packaging & Shippingpacked with

wooden cases After Sales ServicePre-Sales Service* Inquiry and

consulting support.* Sample testing support.* View our

Factory.After-Sales Service* Training how to install the machine,

training how to use the machine. Online Guidance

support.* Engineers available to service machinery

overseas.*12 months guarantee, life-long time technic maintenance

and support.*24 Hours * 7 days service

online.ExhibitionCompany ProfileZhejiang Gaobao machinery Co., LTD

is a professional manufacture of paper and plastic flexible

packaging equipment joint-stock enterprise. It is located in

Wenzhou,Zhejiang, China (Building 9, No.9-11, Hairun Road, Binhai

Development Zone, Pingyang County, Wenzhou City, Zhejiang Province,

China.) with superior geographical location and convenient

transportation. We are focus on Slitting machine, Cutting

machine, A4 paper cutting machine, die-cutting machine and other

equipment products. With more than 20 years' hard working, we

have developed into a integrated company which combine

manufacture, sales and service together. Now, Gaobao has abundant

technical force, perfect processing system and a sound

after-sales service. Learning from domestic and foreign advanced

technology, we combine with market demand and bring our advantages

into play to develop new packing equipment constantly. These are

widely used in roll material processing industry, such as paper,

aluminum foil, plastic and so forth. Due to the high degree of

automation and excellent quality with competitive price, our

products sell very well in domestic. For example, the Sun Paper,

the Five-Star Paper, Kai Lai Paper, Constant Xin Paper products,

Nanjing Jinwei Paper,South sugar Paper and other enterprises, they

are our faithful fans. Also, the products have been exported to the

America, the Middle East, Africa, Southeast Asia, Europe and other

Related products about China Factory Wholesale Price New Automatic Cutting BOPP PE PVC Film Foil Paper Fabric Roll Cutter Slit Slitter Rewinder Slitting Rewinding Making Machine

-

Waste Tyre Plastic Recycling Machinery Machine Tire Crusher Production Line Rubber Crumb Grinding Machine Equipment Tire Shredder

Waste Tyre Plastic Recycling Machinery Machine Tire Crusher Production Line Rubber Crumb Grinding Machine Equipment Tire Shredder

-

Stretch Plastic Blowing Pet Bottle Making Blow Molding Machine Bottles Stretch Automatic Pet Bottle Blowing Machine

Stretch Plastic Blowing Pet Bottle Making Blow Molding Machine Bottles Stretch Automatic Pet Bottle Blowing Machine

-

Waste Plastic Pet Bottle, Water Bottle Flake, PP/HDPE/LDPE PE Film Jumbo Woven Bags Plastic Crusher Machine, Plastic Crushing Washing Recycling Machine

Waste Plastic Pet Bottle, Water Bottle Flake, PP/HDPE/LDPE PE Film Jumbo Woven Bags Plastic Crusher Machine, Plastic Crushing Washing Recycling Machine

-

Type 2 Wall-Mounted Electric Car Charging Station 7kw /11 Kwelectric Vehicle Charging Station Home Wallbox AC EV Charger Single Phase or 3three Phase

Type 2 Wall-Mounted Electric Car Charging Station 7kw /11 Kwelectric Vehicle Charging Station Home Wallbox AC EV Charger Single Phase or 3three Phase

-

G-View G12W Wholesale Auto Car LED Headlight Bulb High Power H13 H11 9005 H7 H4 Car LED Headlights LED Car Lights

G-View G12W Wholesale Auto Car LED Headlight Bulb High Power H13 H11 9005 H7 H4 Car LED Headlights LED Car Lights

-

New Design Porcelain Round Plates Dinner Set for Wedding and Banquet

New Design Porcelain Round Plates Dinner Set for Wedding and Banquet

-

China 2023 New Design Super Soft 100% Polyester Microfiber Knitted Oversized Decoration Hoodie Blanket

China 2023 New Design Super Soft 100% Polyester Microfiber Knitted Oversized Decoration Hoodie Blanket

-

Handmade Art Creative Materials Thickened White Paper Cup DIY Disposable Handmade Colored Paper Cup

Handmade Art Creative Materials Thickened White Paper Cup DIY Disposable Handmade Colored Paper Cup