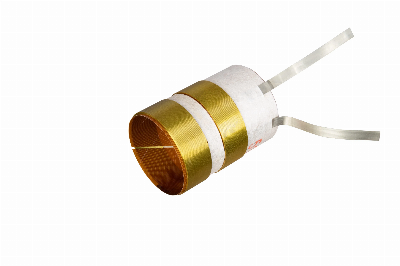

Product DescriptionFunction- A voice coil (consisting of a former,

, and winding) is the coil of wire attached to the apex of a

loudspeaker cone.Advantage- Voice coil also used for voice coil

linear motors, which produce a larger force and move a longer

distance but work on the same principle.Feature- The item provides

the motive force to the cone by the reaction of a magnetic field to

the current passing through it.Style- Light and easy to carry

around, easy to use and has high quality.High temperature voice

coils, with excellent materials and precise dimensionsPure Flat

Aluminum wireFlat Wire Windingcomposite polyimide fiber glass

bobbinwidely used professional audio speaker application.Winding

Height:84mmFormer Height:18.5mm+18.5mmThe Speaker Type

Used:Norminal Diameter18"Power Handling (RMS)800WattPower Handling

(MAX)1600WattImpedance8 OhmFrequency Response33 to

1,000HzSensitivity96dB 2.83V/1mVoice Coil Diameter3"Detailed

PhotosProduct ParametersVoice Coil Technical Parameters:Former

Height 84mmWinding Width 18.5mmOuter

Diameter 79mmInnder Diameter 76.2mmImpedance 5.6

OHMLayers Edge Wound Winding 1 LayerFormer Material USA

Made Impregnated Fiber GlassWire Material/Type Flat Ribbon

Aluminum WirePackaging & ShippingHot Sale Voice Coil

Products1.plastic tray+carton2. foam+carton3. opp bag+box4. also

customizePortshenzhen portLead

time:Quantity(pieces)1 - 10001001 - 1000010001 - 50000>50000Lead

time (days)3715To be negotiated Company ProfileZENITH AUDIO

has produced the voice coils more than 20 years with rich

experience, the various activities in research and development

as well as the use of state-of-the-art technologies make ZENITH

AUDIO the leader in this industry. Combined with solid

production know-how, this forms the foundation for excellent

product quality and opens new paths for future development.Quality

at the highest level - The selection of raw materials can

determine the quality of the finished products. ZENITH AUDIO

uncompromisingly uses high-quality raw materials from

the well-know suppliers to ensure the highest quality

from the step. Further processing and mass production applying

cutting edge technologies, proposing innovative features for

manufacturing equipment and automation technology improvements are

part of our daily business. The results are custom-made the top

quality products - matching exactly the requirements of the

higher demand customers After Sales ServicePrompt Response

TimeExcellent Service and quality productsFAQ1. Question: How to

make custom copper coil?Answer: Please provide the specification,

the drawing would be the best.2. Question: What is the lead time

for sample?Answer: Usually it will take about 3-5 working

days.3.Question: What is the lead time for mass production?Answer:

7-10 days, depending on order quantity.4. Question: What is the

payment terms?Answer: T/T, paypal or negociation. /*

March 10, 2023 17:59:20 */!function(){function s(e,r){var

a,o={};try{e&&e.split(",").forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

Related products about Dual Voice Coil for PRO Audio Speaker Repair Parts

-

Waste Tyre Plastic Recycling Machinery Machine Tire Crusher Production Line Rubber Crumb Grinding Machine Equipment Tire Shredder

Waste Tyre Plastic Recycling Machinery Machine Tire Crusher Production Line Rubber Crumb Grinding Machine Equipment Tire Shredder

-

Stretch Plastic Blowing Pet Bottle Making Blow Molding Machine Bottles Stretch Automatic Pet Bottle Blowing Machine

Stretch Plastic Blowing Pet Bottle Making Blow Molding Machine Bottles Stretch Automatic Pet Bottle Blowing Machine

-

Waste Plastic Pet Bottle, Water Bottle Flake, PP/HDPE/LDPE PE Film Jumbo Woven Bags Plastic Crusher Machine, Plastic Crushing Washing Recycling Machine

Waste Plastic Pet Bottle, Water Bottle Flake, PP/HDPE/LDPE PE Film Jumbo Woven Bags Plastic Crusher Machine, Plastic Crushing Washing Recycling Machine

-

Type 2 Wall-Mounted Electric Car Charging Station 7kw /11 Kwelectric Vehicle Charging Station Home Wallbox AC EV Charger Single Phase or 3three Phase

Type 2 Wall-Mounted Electric Car Charging Station 7kw /11 Kwelectric Vehicle Charging Station Home Wallbox AC EV Charger Single Phase or 3three Phase

-

G-View G12W Wholesale Auto Car LED Headlight Bulb High Power H13 H11 9005 H7 H4 Car LED Headlights LED Car Lights

G-View G12W Wholesale Auto Car LED Headlight Bulb High Power H13 H11 9005 H7 H4 Car LED Headlights LED Car Lights

-

New Design Porcelain Round Plates Dinner Set for Wedding and Banquet

New Design Porcelain Round Plates Dinner Set for Wedding and Banquet

-

China 2023 New Design Super Soft 100% Polyester Microfiber Knitted Oversized Decoration Hoodie Blanket

China 2023 New Design Super Soft 100% Polyester Microfiber Knitted Oversized Decoration Hoodie Blanket

-

Handmade Art Creative Materials Thickened White Paper Cup DIY Disposable Handmade Colored Paper Cup

Handmade Art Creative Materials Thickened White Paper Cup DIY Disposable Handmade Colored Paper Cup