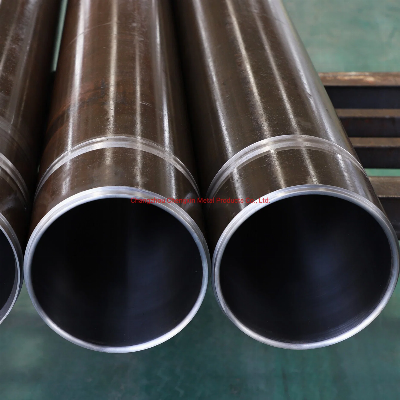

PART I: PRODUCT INTRODUCTION1. Description: Concrete delivery

cylinder is a kind of tube parts made from high precision honed

tubes through machining&turning. Internal surface of cylinder

is hard chrome plated and polished to roughness of Ra0.25um max. 2.

Commodity: S45C seamless steel tube for Concrete pump Delivery

Cylinder 3. Size range: ID of 80mm-280mm 4. Available steel

grade: SAE/AISI1045, 1518,1524DINST52ENE355, C45E, CK45, SAE 10455.

Manufacture procedure: hard chrome plating,

polishing,welding,machining&turning. 6. Thickness of chromed

layer: 0.2mm-0.25mm or as per request. 7. Hardness of chromed

layer: HV850 min 8. Bore rougness after hard chrome plating:

Ra0.25um max. 9. ID tolerance: +0/+0.1mm 10. Standard export

packing: by plywood boxes. 11. Customized packing and

marking can be provided upon request. CONCRETE DELIVERY

CYLINDER: MADE FROM COLD DRAWN TUBES AND PAINTEDCONCRETE DELIVERY

CYLINDER: MADE FROM HOT ROLLED SEAMLESS PIPESCONCRETE DELIVERY

CYLINDER: EXTERNALLY MACHINED SURFACECONCRETE DELIVERY CYLINDER -

WELDING,MACHINING&TURNING:CONCRETE DELIVERY CYLINDER-

PACKING:PART II: FREQUENTLY ASKED QUESTIONS1. MOQ: Generally

Min Order Quantity can be 1 piece/size. 2. Delivery

Time: Generally, delivery time is around 40-60 days depending

on availability of raw material.

3. Warranty&Guarantee: Warranty&guarantee period

is 6 months since we deliver the tubes, and we are not

responsible for quality problem caused by wrong unloading or

storage after shipment. We welcome customer's inspection before

shipment. 4. Payment Method: We accept payment method

like T/T, L/C, or D/P, but it depends on our investigation about

customers. We have a solution to evaluate the credit of

customers from all over the world, and time and amount of D/P we

can release is determined by the evaluation. 5. Quality

Control: 90% of the tubes are made from hot rolled seamless pipes.

So, quality of raw material determined quality of finished tubes.

We purchase raw material from stable suppliers who are leading

steel mills, and we inspect the raw material as per the

specifications. During our production procedure, there is

inspection and quality control in every stage. PART III: FACTORY

FACILITIES:/* March 10, 2023 17:59:20 */!function(){function

s(e,r){var

a,o={};try{e&&e.split(",").forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

Related products about S45c Seamless Steel Tube for Concrete Pump Delivery Cylinder

-

Waste Tyre Plastic Recycling Machinery Machine Tire Crusher Production Line Rubber Crumb Grinding Machine Equipment Tire Shredder

Waste Tyre Plastic Recycling Machinery Machine Tire Crusher Production Line Rubber Crumb Grinding Machine Equipment Tire Shredder

-

Stretch Plastic Blowing Pet Bottle Making Blow Molding Machine Bottles Stretch Automatic Pet Bottle Blowing Machine

Stretch Plastic Blowing Pet Bottle Making Blow Molding Machine Bottles Stretch Automatic Pet Bottle Blowing Machine

-

Waste Plastic Pet Bottle, Water Bottle Flake, PP/HDPE/LDPE PE Film Jumbo Woven Bags Plastic Crusher Machine, Plastic Crushing Washing Recycling Machine

Waste Plastic Pet Bottle, Water Bottle Flake, PP/HDPE/LDPE PE Film Jumbo Woven Bags Plastic Crusher Machine, Plastic Crushing Washing Recycling Machine

-

Type 2 Wall-Mounted Electric Car Charging Station 7kw /11 Kwelectric Vehicle Charging Station Home Wallbox AC EV Charger Single Phase or 3three Phase

Type 2 Wall-Mounted Electric Car Charging Station 7kw /11 Kwelectric Vehicle Charging Station Home Wallbox AC EV Charger Single Phase or 3three Phase

-

G-View G12W Wholesale Auto Car LED Headlight Bulb High Power H13 H11 9005 H7 H4 Car LED Headlights LED Car Lights

G-View G12W Wholesale Auto Car LED Headlight Bulb High Power H13 H11 9005 H7 H4 Car LED Headlights LED Car Lights

-

New Design Porcelain Round Plates Dinner Set for Wedding and Banquet

New Design Porcelain Round Plates Dinner Set for Wedding and Banquet

-

China 2023 New Design Super Soft 100% Polyester Microfiber Knitted Oversized Decoration Hoodie Blanket

China 2023 New Design Super Soft 100% Polyester Microfiber Knitted Oversized Decoration Hoodie Blanket

-

Handmade Art Creative Materials Thickened White Paper Cup DIY Disposable Handmade Colored Paper Cup

Handmade Art Creative Materials Thickened White Paper Cup DIY Disposable Handmade Colored Paper Cup