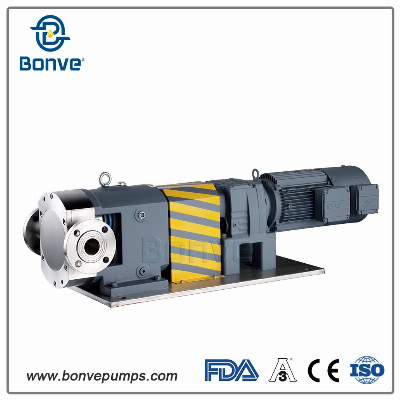

SLES transfer pump / Rotary lobe pump / High viscosity liquid

transfer pump SLES shorts for Sodium laureth sulfate (SLES),

an accepted contraction of sodium lauryl ether sulfate (SLES), is

an anionic detergent andsurfactant found in many personal care

products (soaps, shampoos, toothpaste, etc.). Bonve rotary lobe

pumps are widely used for SLES applications due to the low speed

operation. We named these pumps as SLES transfer pump. The

pump is particularly suitable for the medium that is easy to foam,

high viscosity and high concentration. The pumped product

quality does not change and cannot afford any physical and chemical

reactions. Except SLES, Bonve rotary lobe pumps are ideal to

transfer AES, LABSA, LAS, AOS, K12 too. The pumps are improved to

be no leakage trouble, easy cleaning, low maitenance and long

life.Product DescriptionBonve rotary lobe pumps are designed based

on the exploration of more than 3,000 fluids in various industries.

They are particularly pumping for high viscosity, high solids,

sanitary and corrosive fluids. The pumps are widely used and have

long service life benefits from the below features.1.

Interchangeable rotors, multi connection type and installation

type, fit for various applications.2. Targeted seal for specific

application, ensure a reliable sealing.3. Compact structure, easy

assembling and disassembling.4. Maintenance in place (above the

models of 80BV), easy cleaning, CIPable and SIPable.5. Few wearing

parts, low maintenance.6. All main parts proceed by CNC, high

precision fabrication.7. No contact between the rotors, rotors and

pump chamber.8. Multi bearings with separate arrangement, high

pressure resistance. 9. Axis key synchronous adjustment, no

rotor collision problem.10. The flow can be controlled at will by

frequnecy inverter.11.

Capable to pump the viscous medium from 1cp to 2million cps. 12.

Capable of pumping mixture of gas, fluid and solid medium.Working

principleBonve lobe pumps basically consist of two lobe rotors,

which rotate synchronously driven by a pair of synchronous gears in

the gearbox. The rotors are driven by the main shaft and sub-shaft

to rotate in a synchronous reverse direction, which changes the

pump capacity, builds up high vacuum and discharge pressure, thus

an efficient pumping is formed. Gap is kept between the rotors and

between the pump casing, no friction, long life, no damage, no

physical and chemical reaction to the pumped products.

Detailed PhotosBare shaft pumps with different rotorsComplete unit

pumpsProduct

Parameters ModelDisplacementRPMFlowDis. Pre.PowerSuc. Pre.Port size (L/r)(r/min)(M³/h)(Mpa)(Kw)(Mpa)Std. (mm)Enlar. (mm)40BV12-20.1510-10000-20-0.60.75-2.2-0.080254050BV12-50.3210-8000-50-0.71.5-4-0.095405065BV12-100.6510-6000-100-1.02.2-7.5-0.085506580BV12-201.7410-5000-200-1.24-15-0.085658090BV12-302.4810-5000-300-0.85.5-22-0.09580100100BV12-403.6510-5000-400-1.27.5-30-0.09580 100125BV12-504.6010-5000-500-0.87.5-37-0.095100125140BV12-706.1010-5000-700-1.211-45-0.095125150150BV12-807.6310-5000-800-1.211-55-0.095125150200BV12-12011.5610-4000-1200-1.215-75-0.095150200250BV12-15014.2210-4000-1500-1.218.5-90-0.095150250300BV12-20020.8010-3000-2000-1.222-110-0.095200300350BV12-30032.6010-2500-3000-1.245-160-0.095250350400BV12-40050.4010-2500-4000-1.255-200-0.095350400Remarks:

1. Tested medium in the table: water. 2. Speed, flow

rate, electrical power and pressure will be varified according to

different liquid properties. 3. Port size can be changed as

needed. 4. Bonve reserves the right to change specifications

without prior notification.8 steps for your guideline to select

Bonve pump 1. Your product name2. Product viscosity in pump, line

and at rest3. Are there any solids present, if so what are

they and percentage concentration4. Specific

gravity5. Capacity required6. Pumping

temperature7. Discharge pressure or sketch of pipework

system8. Suction pressure or sketch of pipework system

Applications and site photosAbout usBONVE is a Chinese leading

manufacturer in ROTARY LOBE PUMPS and HOMOGENIZER MIXERS,

ISO9001:2015 approved company. Providing its customers with

customized pumping and mixing solutions and solving their problems

during the production. Bonve has more than 20 years of

expertise and technical know how. We design, R&D and produce.

When you choose a Bonve pump, you not only get the high quality

pumps, but you also get the advantage of Bonve's engineering

expertise and years of application knowledge in the food, chemical,

pharmaceutical, cosmetics industries etc.By 2021, we have obtained

more than 30 patents, such as invention patents, utility model

patents. Owns one set of full automatically pump testing system,

98 sets of advanced CNC machines, including mills, borers,

lathes, drillers, grinders, machining centers etc. and a variety of

precise inspection equipment.Bonve pumps are acknowledged and used

over 40 countries around the world. By 2021, more than 5000

companies used Bonve pumps and over 60000 units pu

Related products about SLES Transfer Pump / Rotary Lobe Pump / High Viscosity Liquid Transfer Pump

-

Waste Tyre Plastic Recycling Machinery Machine Tire Crusher Production Line Rubber Crumb Grinding Machine Equipment Tire Shredder

Waste Tyre Plastic Recycling Machinery Machine Tire Crusher Production Line Rubber Crumb Grinding Machine Equipment Tire Shredder

-

Stretch Plastic Blowing Pet Bottle Making Blow Molding Machine Bottles Stretch Automatic Pet Bottle Blowing Machine

Stretch Plastic Blowing Pet Bottle Making Blow Molding Machine Bottles Stretch Automatic Pet Bottle Blowing Machine

-

Waste Plastic Pet Bottle, Water Bottle Flake, PP/HDPE/LDPE PE Film Jumbo Woven Bags Plastic Crusher Machine, Plastic Crushing Washing Recycling Machine

Waste Plastic Pet Bottle, Water Bottle Flake, PP/HDPE/LDPE PE Film Jumbo Woven Bags Plastic Crusher Machine, Plastic Crushing Washing Recycling Machine

-

Type 2 Wall-Mounted Electric Car Charging Station 7kw /11 Kwelectric Vehicle Charging Station Home Wallbox AC EV Charger Single Phase or 3three Phase

Type 2 Wall-Mounted Electric Car Charging Station 7kw /11 Kwelectric Vehicle Charging Station Home Wallbox AC EV Charger Single Phase or 3three Phase

-

G-View G12W Wholesale Auto Car LED Headlight Bulb High Power H13 H11 9005 H7 H4 Car LED Headlights LED Car Lights

G-View G12W Wholesale Auto Car LED Headlight Bulb High Power H13 H11 9005 H7 H4 Car LED Headlights LED Car Lights

-

New Design Porcelain Round Plates Dinner Set for Wedding and Banquet

New Design Porcelain Round Plates Dinner Set for Wedding and Banquet

-

China 2023 New Design Super Soft 100% Polyester Microfiber Knitted Oversized Decoration Hoodie Blanket

China 2023 New Design Super Soft 100% Polyester Microfiber Knitted Oversized Decoration Hoodie Blanket

-

Handmade Art Creative Materials Thickened White Paper Cup DIY Disposable Handmade Colored Paper Cup

Handmade Art Creative Materials Thickened White Paper Cup DIY Disposable Handmade Colored Paper Cup