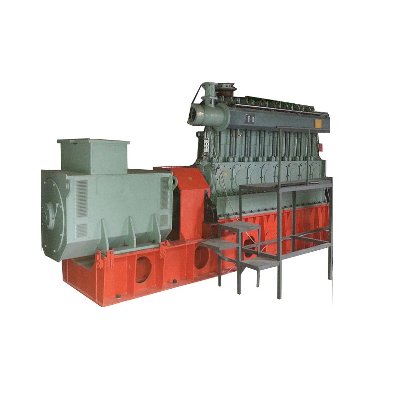

Agricultural Waste/ Chicken Manure /Cow Dung Biomass Gasifier for

Power GenerationSyngas-biomass generations are driven by low speed

300 series engines, the gas fuel can be generated from gasification

of MSW, woodchips, sawdusts, rice husks, straws, coconut shells,

coal gas, coking gas, coke oven gas and pyrolysis gas etc. Low

Speed 300 engines are specially designed for syngas as fuel, with

remarkable features of low speed, big cylinder, big displacement,

naturally aspirated and strong resistance ability against the TAR,

highly reliable, durable, the overhaul can reachover 60000

hours.Gas Quality SuggestedGas temperature≤40ºCGas pressure

2.5~10kPaPressure change rate≤1kPa/minGas calorific value ≥

4.0MJ/Nm3Moisture content≤40g/Nm3, no free water Impurity

size≤5μmImpurity content≤30mg/Nm3Tar

content≤50mg/Nm3H2S≤50mg/Nm3Total

sulfur≤100mg/Nm3NH3≤20mg/Nm3C6H6≤50 mg/Nm3C10H8≤50

mg/Nm3H2≤60%O2≤1%Gas Generator Specification ItemTechnical

specificationEngineModel6300D/M6300D/M-18300D/M-28300D/M-39300D/M-19300ZLD/MTypeInline,

water cooled, four stroke, spark plug

ignitionNon-turbochargedTurbochargedCylinder number689Cylinder

diameter (mm)300Rated speed(r/min)500600600600750600Rated power

(kW)3304405506608801320Rated thermal

consumption(MJ/kW·h)≤11.0Rotate direction (From

flywheel)ClockwiseStart modeCompressed air /motor startCompressed

air startExhaust temperature (ºC)≤600≤650Oil

consumption(g/kW·h)≤0.8≤1.0Generator

setType300GFM400GFM500GFM600GFM800GFM1200GFMRated

power(kW)3004005006008001200Frequency(HZ)50Voltage(V)400/6300/10500Current(A)541/34/21722/46/28902/57/34

1083/69/411443/92/552165/137/82Power factor (COSΦ)0.8

(Lagging)Phase and connecting 3phases 4wires /3phases

3wiresDimension (L×W×H)

(mm)5800×1600×29006400×1600×29008500×1900×35008500×1900×3700Weight(kg)18000220004100042000Customer

Benefits for Syngas Engines• Cylinders Structure in Line &

Upright & Concise Layout, which means simple, easy and low cost in

operation & maintenance. Engine-Overhaul can be handled at user's

site.• Large cylinder (300mm), long stroke, low speed and big

displacement 215L and 242L, which means big reserve power capacity

and constant power output.• Low engine speed at 500 or 600rpm,

which means high reliability for continuous operation, sufficient

combustion, low exhaust gas temperature and high heat

efficiency.• Naturally aspirated (no turbocharger and

Intercooler), which means low failure rate and minimum downtime

(TAR in syngas always block and damage turbocharger and

intercooler).• Internal mixing system (for high hydrogen gas

over 15%), gas and air intake separately, then mixed in combustion

room, which means no risk of backfire and cylinder

knocking.• Strong treatment and resistance ability against

TAR, long term trouble free operation. TAR always raises problems

ofpipeline-blocking, cylinder-pollution and spark plug-jamming

etc.• Compressed Air Starting System, smooth starting, high

success rate and easy for maintenance.• Open Cooling System,

adopting plate-type heat exchanger, high efficiency and easy for

scale-removal.• Dismountable intake-valve-box, which means can

clean TAR easily and conveniently (no need disassembling of

cylinder head).• Low-speed engine makes the noise lower. The

maximum noise ≤100dB. Through silencer, the noise will be

≤70dB.• Low speed means low components wearing, namely lower

cost in spare parts replacement and long life span.• Long

Overhaul Time of 60,000 hours and lifecycle of 20-25 years, which

ensure sustainable financial rewards of power plant.

Applicable Gas Fuels • Biomass from MSW, Woodchips,

Sawdust, Straw, Rice husks, Nut-shells, and Chicken manure etc.

• Industrial tail gas & refinery gas, such as coal gas,

coking gas, semi-coke gas, coke oven gas, oilshell tail gas,

carbide tail gas, ferrochromium tail gas, yellow phosphorus tail

gas, producer gas and paralysis gas etc. 6MW Woodchip Biomass

Power Plant in CroatiaWaste to Energy project, 13x500kW syngas

engines running in parallel, synchronized with utility. By using

feedstocks of woodchips & rice husks, through biomass gasifier to

produce combustible gas fuel, for cogeneration of electricity (for

exporting energy) & hot steam (for drying feestocks) & byproducts

of biochars, forming a comprehensive energy utilization

system.Applications Why Zichai Gas Generator Set?1.

Development and manufacturing internal combustion engine since

19702. Factory area over 330000m2 & over 2200 employees3.

Highly versatile power generator with ability to handle more than

20 different gases4. More than 200 employees dedicated to

developing and improving power generator for various gas.5. More

than 1000 systems installed in over 20 countries using

a variety of gases.6. More than 50 people in the Customer

Service Department making the Organization very Customer

Responsive.Project ReferencesOur

customersPacking&ShippingFAQ1.Are you a trading company or

manufacture?Manufacture with factory.2.What kinds of gas generator

set do you produce?It covers

Related products about Agricultural Waste/ Chicken Manure /Cow Dung Biomass Gasifier for Power Generation

-

Waste Tyre Plastic Recycling Machinery Machine Tire Crusher Production Line Rubber Crumb Grinding Machine Equipment Tire Shredder

Waste Tyre Plastic Recycling Machinery Machine Tire Crusher Production Line Rubber Crumb Grinding Machine Equipment Tire Shredder

-

Stretch Plastic Blowing Pet Bottle Making Blow Molding Machine Bottles Stretch Automatic Pet Bottle Blowing Machine

Stretch Plastic Blowing Pet Bottle Making Blow Molding Machine Bottles Stretch Automatic Pet Bottle Blowing Machine

-

Waste Plastic Pet Bottle, Water Bottle Flake, PP/HDPE/LDPE PE Film Jumbo Woven Bags Plastic Crusher Machine, Plastic Crushing Washing Recycling Machine

Waste Plastic Pet Bottle, Water Bottle Flake, PP/HDPE/LDPE PE Film Jumbo Woven Bags Plastic Crusher Machine, Plastic Crushing Washing Recycling Machine

-

Type 2 Wall-Mounted Electric Car Charging Station 7kw /11 Kwelectric Vehicle Charging Station Home Wallbox AC EV Charger Single Phase or 3three Phase

Type 2 Wall-Mounted Electric Car Charging Station 7kw /11 Kwelectric Vehicle Charging Station Home Wallbox AC EV Charger Single Phase or 3three Phase

-

G-View G12W Wholesale Auto Car LED Headlight Bulb High Power H13 H11 9005 H7 H4 Car LED Headlights LED Car Lights

G-View G12W Wholesale Auto Car LED Headlight Bulb High Power H13 H11 9005 H7 H4 Car LED Headlights LED Car Lights

-

New Design Porcelain Round Plates Dinner Set for Wedding and Banquet

New Design Porcelain Round Plates Dinner Set for Wedding and Banquet

-

China 2023 New Design Super Soft 100% Polyester Microfiber Knitted Oversized Decoration Hoodie Blanket

China 2023 New Design Super Soft 100% Polyester Microfiber Knitted Oversized Decoration Hoodie Blanket

-

Handmade Art Creative Materials Thickened White Paper Cup DIY Disposable Handmade Colored Paper Cup

Handmade Art Creative Materials Thickened White Paper Cup DIY Disposable Handmade Colored Paper Cup