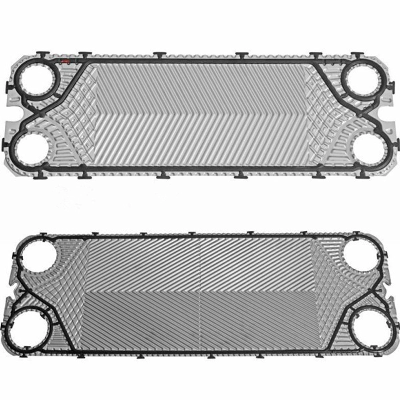

Plate heat exchanger plate is specially used to isolate medium and

conduct heat exchange in plate heat exchanger, which is an

important part of plate heat exchanger. Its main materials include

stainless steel (SUS304.316), titanium and titanium palladium (Ti,

Ti Pd), 20Cr, 18Ni, 6Mo (254SMO), alloy (C276), copper (H68),

etc. Plate TypeSingle plate for PHEFlow Channel Between

Plates3.5mm ~12.0mm (Optional depends on working condition)Plate

Thickness0.4mm ~ 1.0mmHeat Transfer Plate MaterialStainless steel

304, 316/316L, 254 SMO, Titanium, Hastelloy C-276, othersGasket

MaterialNBR, EPDM, HNBR, HEPDM, NBR-HT, FKM, Viton A, Viton

GPressure Plate MaterialCarbon steel, stainless steel and others on

requestTemperature Range-50ºC ~ +180ºC Varies with the media and

gasket selection.Maximum PressureMaximum standard pressure 10 bar /

16 barPort ConnectionDN32, DN50, DN80, DN125, DN150, DN200, DN250,

DN350 BrandsModelAlfa lavaleM3, M15B, MX25B, TL10, M6B,

M15M, MX25M, TL6, M6M, T20B, AK20M, P16, M10B, M20M, TS6M, P26,

M10M, M30B, TS20M, P36APVH17,N35, J185, J107, J092,

J060GEAVT04,VT10,VT20,NT50X,NT50T,NT50M,NT100T,NT100M,NT100X,NT150L,NT150S,NT250S,NT250M,NT250L,NT350M,NT350L,NT350S,NT500T,NT500M,NT500XSwepGL13,GX60,GX145 ,GX18,GX64,GC26,GX26,GX85,GC51,GX42,GX91,GC60,GX51,GX100SondexS4,S7,S8,S9,S14,S19,S21,S22,S31,S37,S41,S42,S43,S62,S65,S81,S100,S121VicarbV4,V8,V13,V20,V28,V45,V60,V110,V130FunkeFP02,FP04,FP08,FP10,FP14,FP16,FP20,FP22,FP31,FP40,FP41,FP50,FP60,FP80,FP205ThermowaveTL90,TL150,TL200,TL250,TL400,TL500,TL650 We

are developing more models, welcome your inquiry. If you need a

large number of plates, we can also customize the mold for you.High

temperature corrosion resistance:The plate is made of

304/316L/titanium plate/Hastelloy high-strength corrosion-resistant

material, free from high temperature medium, and has a long service

life.Corrugated runner, high heat transfer: The special corrugated

structure of the plate enables the fluid to obtain a high heat

transfer coefficient at a low flow rate, which is 3-5 times that of

the traditional shell.Diversion area design, less scaling: The

design of the split flow area has high plate pressing accuracy,

uniform surface medium flow rate, pressure drop, and is not easy to

scale, which can improve the overall heat transfer

efficiency.Complete molds: Imported plate exchange and domestic

plate exchange, complete molds, meet a variety of media and working

conditions, select a variety of adhesive strips, and have a wide

range of applications.We provide various plate-like patterns with

different pressing depths and angles to allow the media containing

particles and fibers to pass through the free flow pattern of the

heat exchanger unhindered. /* March 10, 2023 17:59:20

*/!function(){function s(e,r){var

a,o={};try{e&&e.split(",").forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

Related products about S4/S7/S8/S9/S14/S19/S21/S22 Titanium Alloy C276 Heat Exchanger Plate

-

Waste Tyre Plastic Recycling Machinery Machine Tire Crusher Production Line Rubber Crumb Grinding Machine Equipment Tire Shredder

Waste Tyre Plastic Recycling Machinery Machine Tire Crusher Production Line Rubber Crumb Grinding Machine Equipment Tire Shredder

-

Stretch Plastic Blowing Pet Bottle Making Blow Molding Machine Bottles Stretch Automatic Pet Bottle Blowing Machine

Stretch Plastic Blowing Pet Bottle Making Blow Molding Machine Bottles Stretch Automatic Pet Bottle Blowing Machine

-

Waste Plastic Pet Bottle, Water Bottle Flake, PP/HDPE/LDPE PE Film Jumbo Woven Bags Plastic Crusher Machine, Plastic Crushing Washing Recycling Machine

Waste Plastic Pet Bottle, Water Bottle Flake, PP/HDPE/LDPE PE Film Jumbo Woven Bags Plastic Crusher Machine, Plastic Crushing Washing Recycling Machine

-

Type 2 Wall-Mounted Electric Car Charging Station 7kw /11 Kwelectric Vehicle Charging Station Home Wallbox AC EV Charger Single Phase or 3three Phase

Type 2 Wall-Mounted Electric Car Charging Station 7kw /11 Kwelectric Vehicle Charging Station Home Wallbox AC EV Charger Single Phase or 3three Phase

-

G-View G12W Wholesale Auto Car LED Headlight Bulb High Power H13 H11 9005 H7 H4 Car LED Headlights LED Car Lights

G-View G12W Wholesale Auto Car LED Headlight Bulb High Power H13 H11 9005 H7 H4 Car LED Headlights LED Car Lights

-

New Design Porcelain Round Plates Dinner Set for Wedding and Banquet

New Design Porcelain Round Plates Dinner Set for Wedding and Banquet

-

China 2023 New Design Super Soft 100% Polyester Microfiber Knitted Oversized Decoration Hoodie Blanket

China 2023 New Design Super Soft 100% Polyester Microfiber Knitted Oversized Decoration Hoodie Blanket

-

Handmade Art Creative Materials Thickened White Paper Cup DIY Disposable Handmade Colored Paper Cup

Handmade Art Creative Materials Thickened White Paper Cup DIY Disposable Handmade Colored Paper Cup