Sample Available 120980 Extended Nozzle for Powermax1000/1250/1650

TR60/RT80What are plasma cutter consumables?Plasma cutter

consumables are a set of components in your plasma cutter that

gradually wear over time until they need to be replaced: they have

a life cycle. The consumables are all found in the cutting torch

itself, which is where most of the energy is focussed, and keeping

track of wear and tear is a key part of maintaining an efficient

machine that cuts well and lasts a long time. Plasma cutting torch

consumables include: a swirl ring, electrode, nozzle, retaining

cap, and shield cap. Product DescriptionNozzle:The nozzle

focuses the plasma arc and the gas that surrounds it to make a

clean and precise cut. A nozzle with a largeropening is used for

gouging, while a nozzle with a smaller opening is better able to

direct the gas and so is used for fine, detailed workPart

Number120259Item Weight7.4 ouncesProduct Dimensions2 x 2 x 0.7

inchesOperatin Range200APlasma Power SourceHT2000MaterialCopperItem

Package Quantity1Electrode:The electrode is a narrow piece of

copper containing hafnium (which is an excellent conductor of

electricity). Its job is to receive the electrical current from a

cathode block inside the torch to which it is connected, and to

focus the charge through its tip, which causes it to arc onto the

workpiece. Retaining cap:The retaining cap essentially holds

all of the consumable parts of the torch together. As temperatures

at this end of the machine are extremely high, it's not just the

parts creating and focussing the arc that are worn down; the

component holding them together also degrades over time. Part

Number120837Item Weight2.46ouncesProduct Dimensions4.72 x 3.15 x

1.57 inchesOperatin Range100A-200APlasma Power

SourceHT2000Item Package Quantity1 Shield cap:The shield is

there to protect the torch and its other components from the sparks

and molten metal that result from the plasmacutting process. It

takes the brunt of the fallout so that wear to other components is

minimised as much as possible.Product ParametersPart

Number220976Item Weight1.76 ouncesProduct Dimensions3.94 x 3.94 x

1.97InchesOperatin Range105A-125APlasma Power SourcePowermax

125Item Package Quantity5Swirl ring:The function of the swirl ring

is to spin the plasma gas which has two main results; 1,

The spinning gas is gyroscopically stabilised a bit like a bullet

making the plasma column less tendency to deflect. Part

Number120833Item Weight0.246ouncesProduct Dimensions1 x 1 x6

InchesOperatin Range105A-125APlasma Power

SourceHT2000Package1 Application Package

and Delivery Company ProfileEstablished in

2017, ALLWINCNC are a manufacturing company specializing in the

production of plasma and laser consumables. We want to build

long-term relationships with customers rather than developing

one-off deals.By providing our products to help you succeed in

your endeavors.The core idea of ALLWIN is our commitment to

achieving mutual success for our customers, shareholders, and

employees through collaboration.Certifications Consumable

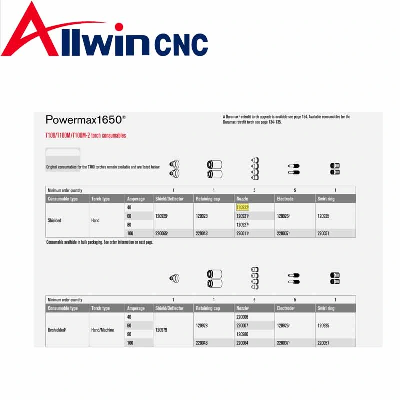

listTherefore we will provide you with an overview of all current

and legacy Hypertherm plasma cutting systems, so you could see

which option fits best your needs. We can provide the

Hypertherm, Thermadyne, Kaliburn, kjellberg ,Esab,Lincoln etc

brand. NoPart NoDescription1120932Nozzle 40A2120931Nozzle

60A3120927Nozzle 80A4120926Electrode

40-80A 5120925Swirl Ring

40-80A 6120930Shield 40-80A 7120929Shield

40-80A 8120928Retaining Cap

40-80A 9220011Nozzle 100A10220037Electrode 100A11220047Shield

100A 12220048Retaining Cap 100A13220051Swirl Ring

100A14220006Nozzle 40A15220007Nozzle 60A16220329Nozzle 40A

Finecut17220064Nozzle 100A18220065Shield 100A 19228523Powermax

1650 main body20120980Nozzle 80A21128643T60M/T80M/T100M/Rt80M

mounting sleeve22120979Deflector23220206Retaining Cap

100A24220061Retaining Cap OHMIC25220059Nozzle Gouging

60-80A26220063Nozzle Gouging 100A FAQQuestion : How about your

after service?Answer : Technical support by phone, e-mail or MSN

around the clock.Question : How can we install the

consumables?Answer : Friendly English version manual and operation

video CD disk.Question : How do I choose the right consumables for

my machine?Answer : According to your needs and budget, we will

provide the best answer for your efficient production.Question :

How about the payment terms?Answer : 30% T/T for deposit, 70%T/T

paid before shipping. Question : When can I get the

price?Answer : We usually quote within 24 hours after we get your

inquiry. If you are very urgent to get the price, please tell us in

your email so that we will regard you inquiry priority.Question :

Can I get a lower price if I order large quantities?Answer : Yes,

once the order is confirmed, you will enjoy our factory

price.Question: Which port is the nearest from your company?Answer

: The Qingdao port is the nearestQuestion: Can I have a visit to

your factory before the order?Answer : Yes,

Related products about Sample Available 120980 Extended Nozzle for Powermax1000/1250/1650 Tr60/Rt80

-

Waste Tyre Plastic Recycling Machinery Machine Tire Crusher Production Line Rubber Crumb Grinding Machine Equipment Tire Shredder

Waste Tyre Plastic Recycling Machinery Machine Tire Crusher Production Line Rubber Crumb Grinding Machine Equipment Tire Shredder

-

Stretch Plastic Blowing Pet Bottle Making Blow Molding Machine Bottles Stretch Automatic Pet Bottle Blowing Machine

Stretch Plastic Blowing Pet Bottle Making Blow Molding Machine Bottles Stretch Automatic Pet Bottle Blowing Machine

-

Waste Plastic Pet Bottle, Water Bottle Flake, PP/HDPE/LDPE PE Film Jumbo Woven Bags Plastic Crusher Machine, Plastic Crushing Washing Recycling Machine

Waste Plastic Pet Bottle, Water Bottle Flake, PP/HDPE/LDPE PE Film Jumbo Woven Bags Plastic Crusher Machine, Plastic Crushing Washing Recycling Machine

-

Type 2 Wall-Mounted Electric Car Charging Station 7kw /11 Kwelectric Vehicle Charging Station Home Wallbox AC EV Charger Single Phase or 3three Phase

Type 2 Wall-Mounted Electric Car Charging Station 7kw /11 Kwelectric Vehicle Charging Station Home Wallbox AC EV Charger Single Phase or 3three Phase

-

G-View G12W Wholesale Auto Car LED Headlight Bulb High Power H13 H11 9005 H7 H4 Car LED Headlights LED Car Lights

G-View G12W Wholesale Auto Car LED Headlight Bulb High Power H13 H11 9005 H7 H4 Car LED Headlights LED Car Lights

-

New Design Porcelain Round Plates Dinner Set for Wedding and Banquet

New Design Porcelain Round Plates Dinner Set for Wedding and Banquet

-

China 2023 New Design Super Soft 100% Polyester Microfiber Knitted Oversized Decoration Hoodie Blanket

China 2023 New Design Super Soft 100% Polyester Microfiber Knitted Oversized Decoration Hoodie Blanket

-

Handmade Art Creative Materials Thickened White Paper Cup DIY Disposable Handmade Colored Paper Cup

Handmade Art Creative Materials Thickened White Paper Cup DIY Disposable Handmade Colored Paper Cup