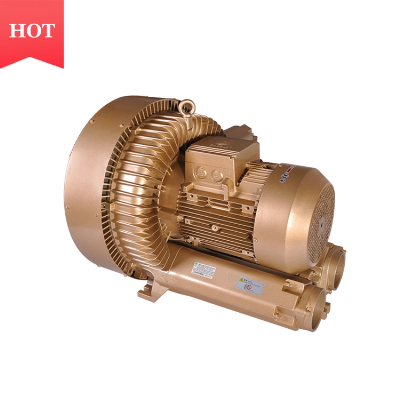

Product ParametersProduct Name17HP Double Stage High Capacity

Turbine Blowers for Dust

CollectionModel No.GHBH 017 36 1R9Frequency50Hz60HzRated Power12.5kW14.5kWRated Voltage345-415△/600-690Y (V)380-480△/660-720Y (V)Rated Current28.0△/16.2Y (A) 29.0△/16.7Y (A)Max Airflow1050m³/h1250m³/hMax Vacuum-290mbar-270mbarMax Pressure280mbar260mbarSound74db(A)79db(A)Weight116kg116kgProduct

FeaturesGOORUI Side channel blowers are maintenance-free:·External,

permanently lubricated bearings·Contactless rotating

impellers·Fan-cooled motorsGOORUI Side channel blowers are

user-friendly:·Weight-optimised design through aluminum pressure

casting parts·Possibility for a vertical or horizontal

installation·Suitability for converter operationGOORUI Side channel

blowers are environmentally friendly:·Oil-free operation·Low energy

requirement·Low noise emissionGOORUI Side channel blowers can be

used world-wide:·50/60Hz voltage range motors of the Iso class

F·Protection type IP55 with an integrated thermal protection switch

(standard)·CE, TUV, RoHS, CCC and ISO9001 certificationsPerformance

CurvesDimensionsDetailed PhotosAccessoriesWe also have some parts

for your application, if you need, welcome to tell me.Air filter:

Filter the dust particles, apply to a bad environment.Silencer:

reduce blower noise 5-10db, apply to a quiet

environment.Pressure relief valve: Control gas pressure, prevent

excessive pressure, damage the machine.Installation

InstructionsInstructions:1. It should be placed in a relatively

stable place, and the surrounding environment should be clean, dry

and ventilated.2. The direction of rotation of the impeller must be

consistent with the direction of the pointed tip marked on the fan

cover.3. When working, the working pressure should not be greater

than 8 kPa, so as to avoid excessive heat generation of the air

pump and damage to the air pump caused by motor overcurrent.4. It

is strictly forbidden for solid, liquid and corrosive gas to enter

the pump body.5. The filters and silencers at both ends of the air

inlet and outlet should be cleaned in time according to the

situation to avoid clogging and affecting use.6. The external

connection of the air inlet and outlet must be connected by a hose

(rubber tube, plastic spring tube).Precautions:1. Flat washers and

spring washers must be used to tighten the screws.2. It is best to

use rubber buffer rubber to bear the weight of the vortex air pump,

especially the high-power vortex air pump, which is

indispensable.3. For some occasions that require noise, a silencer

can be installed to reduce the noise (generally down, about 5 dB),

the silencer is installed at the end of the inlet duct or outlet

duct.4. For some occasions with high requirements for noise, you

can add a layer of silencer cotton according to the conditions of

the machine itself to meet the noise requirements on site. For

details, please consult our customer service.5. When using

silencing cotton to silence the sound, pay attention to the

distance between the vortex air pump and the box, pay attention to

the ventilation and heat dissipation of the vortex air pump, and

pay attention to using rubber cushioning to bear the weight of the

vortex air pump.According to the picture, you need to consult

customer service.6. The air inlet and outlet of the vortex air pump

For pipe connection, hose connection should be used to isolate

vibration./* March 10, 2023 17:59:20 */!function(){function

s(e,r){var

a,o={};try{e&&e.split(",").forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

Related products about 17HP Double Stage High Capacity Turbine Blowers for Dust Collection

-

Waste Tyre Plastic Recycling Machinery Machine Tire Crusher Production Line Rubber Crumb Grinding Machine Equipment Tire Shredder

Waste Tyre Plastic Recycling Machinery Machine Tire Crusher Production Line Rubber Crumb Grinding Machine Equipment Tire Shredder

-

Stretch Plastic Blowing Pet Bottle Making Blow Molding Machine Bottles Stretch Automatic Pet Bottle Blowing Machine

Stretch Plastic Blowing Pet Bottle Making Blow Molding Machine Bottles Stretch Automatic Pet Bottle Blowing Machine

-

Waste Plastic Pet Bottle, Water Bottle Flake, PP/HDPE/LDPE PE Film Jumbo Woven Bags Plastic Crusher Machine, Plastic Crushing Washing Recycling Machine

Waste Plastic Pet Bottle, Water Bottle Flake, PP/HDPE/LDPE PE Film Jumbo Woven Bags Plastic Crusher Machine, Plastic Crushing Washing Recycling Machine

-

Type 2 Wall-Mounted Electric Car Charging Station 7kw /11 Kwelectric Vehicle Charging Station Home Wallbox AC EV Charger Single Phase or 3three Phase

Type 2 Wall-Mounted Electric Car Charging Station 7kw /11 Kwelectric Vehicle Charging Station Home Wallbox AC EV Charger Single Phase or 3three Phase

-

G-View G12W Wholesale Auto Car LED Headlight Bulb High Power H13 H11 9005 H7 H4 Car LED Headlights LED Car Lights

G-View G12W Wholesale Auto Car LED Headlight Bulb High Power H13 H11 9005 H7 H4 Car LED Headlights LED Car Lights

-

New Design Porcelain Round Plates Dinner Set for Wedding and Banquet

New Design Porcelain Round Plates Dinner Set for Wedding and Banquet

-

China 2023 New Design Super Soft 100% Polyester Microfiber Knitted Oversized Decoration Hoodie Blanket

China 2023 New Design Super Soft 100% Polyester Microfiber Knitted Oversized Decoration Hoodie Blanket

-

Handmade Art Creative Materials Thickened White Paper Cup DIY Disposable Handmade Colored Paper Cup

Handmade Art Creative Materials Thickened White Paper Cup DIY Disposable Handmade Colored Paper Cup