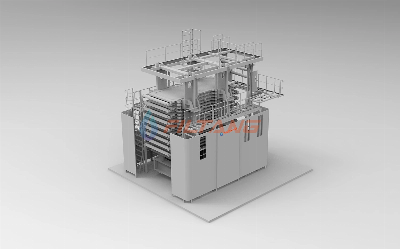

Filtang IVFP Intelligent Vertical Tower Filter PressDesign

philosophySmall land occupation, low moisture In the beginning of a

filtration circulation, ring-shaped filter cloth as a whole passes

through shut filter plate group and slurry pump in sequence in S

shape and enters into closed slurry chamber, a part of filtration

liquid penetrates filter cloth within filter plates and grille in

order due to its own gravity and pressure of pump and discharges,

and thereafter rubber membrane above slurry chamber inflates to

provide full filter pressing for the slurry. In this process,

filter cake can be future dried up or washed through air blowing

and spray. After washing is completed, hydraulic cylinder drives

filter plate to open along the direction of guide rail, motor

drives filter cloth to operate one circle towards the direction of

washing water tank. Filter cake diverts by filter cloth and

materials are unloaded by scraper at both ends of filter plate.

After being detected by deviation rectifier and possible position

deviation is rectified, continue to perform the next round of

filtration. Technique featuresAutomatic operations Filters applied

in multiple industrial fields including chemical engineering,

tailing, environment protection include PF vertical filter press,

FFP and HVPF vertical filter press filter press and so forth, and

PF model takes up a leading position in filtration of fine

particles. Filtang IVFP intelligent vertical filter press is

developed from PF, and compared to PF model, the majority of parts

are upgraded. Same as PF, FFP and HVPF vertical filter press

filters, it is suitable for filtration of fine particles.

Meanwhile, it remarkably decreases filtration circulation time

compared to general plate-and-frame filter. For general materials,

averagely it takes approximately 10 minutes for a single

circulation. StructureDefine filter cake As to sticky and fine

materials, due to filter cake's own gravity, pressure of feed-in

pump, and high-strength pressing of rubber membrane, final filter

cake moisture is extremely low. Since slurry chamber is horizontal,

feed-in time exponentially reduces compared to horizontal filter

press, distribution of solid particles is even, filter cake

thickness is even, and effective filter cake washing can be

performed. BenefitsImprove profit ratioFabric characteristics and

strong membrane pressure of IVFP intelligent vertical filter press

enables to bring ultimately low filter cake moisture, and washing

is more thorough. This suggests better product quality, lower

transportation cost of finished products, and all these will bring

estimative benefits for our clients. Application

industriesFor fine chemical, ultrafine particles etc.The model of

equipment has been tested for many years, possessing the advantages

of superb performance/price ratio, good filtration efficiency,

large production capability, good washing outcome and flexible

operations. It is widely used in solid-liquid separation in

industries including chemical engineering, pharmaceutical,

metallurgy, dye, food and environment protection, in particular,

more applied in filtration of concentrate, tailing, hydrometallurgy

products, chemical products such as ultrafine aluminum hydroxide,

graphene, lithium iron phosphate and leach residue.

Filtration Area m²Plate Size mmPlate NumberWeight TSize(L×W×H)mm11000×550282500×1500×20002492500×1500×220031750×9002143500×2500×220064153500×2500×230096163500×2500×2500128173500×2500×27001510183500×2500×29001812193500×2500×31002114213500×2500×33002416223500×2500×34002718233500×2500×3600152500×10206375100×3700×3300208395100×3700×36002510425100×3700×39003012435100×3700×42003514445100×3700×45004016455100×3700×48004518465100×3700×51005020485100×3700×54005522505100×3700×5700604010×150010976900×4500×540072121006900×4500×580084141046900×4500×620096161106900×4500×6500108181126900×4500×6900120201186900×4500×7200132221206900×4500×7600144241236900×4500×7900156261266900×4500×8300168281306900×4500×86001446020×1500161429200×5500×6800162181479200×5500×7200180201509200×5500×7500198221609200×5500×7800216241669200×5500×8200234261729200×5500×8500252281809200×5500×8800270301909200×5500×9200FILTANGOur

mission is to develop industrial filtration technology and promote

sustainabledevelopment of the worldOn June 24, 2019, a group of

engineers who wish to prove that new filtration technology is

better, faster and has more possibilities than traditional

filtration technology created Filtang. Filtang not only has the

capability in developing high-end filtration technology, but also

promotes the development of the overall industry by spreading the

new intelligent technology. Filtang believes that human's prospect

will be more wonderful if industrial filtration technology stays

away from the reliance on limited water resource and energy and

moves forward to zero emission earlier.Filtang carried out research

and development work on horizontal vacuum filter, rotary table

vacuum filter, dynamic fi

Related products about Filtang Ivfp Intelligent Vertical Tower Filter Press

-

Waste Tyre Plastic Recycling Machinery Machine Tire Crusher Production Line Rubber Crumb Grinding Machine Equipment Tire Shredder

Waste Tyre Plastic Recycling Machinery Machine Tire Crusher Production Line Rubber Crumb Grinding Machine Equipment Tire Shredder

-

Stretch Plastic Blowing Pet Bottle Making Blow Molding Machine Bottles Stretch Automatic Pet Bottle Blowing Machine

Stretch Plastic Blowing Pet Bottle Making Blow Molding Machine Bottles Stretch Automatic Pet Bottle Blowing Machine

-

Waste Plastic Pet Bottle, Water Bottle Flake, PP/HDPE/LDPE PE Film Jumbo Woven Bags Plastic Crusher Machine, Plastic Crushing Washing Recycling Machine

Waste Plastic Pet Bottle, Water Bottle Flake, PP/HDPE/LDPE PE Film Jumbo Woven Bags Plastic Crusher Machine, Plastic Crushing Washing Recycling Machine

-

Type 2 Wall-Mounted Electric Car Charging Station 7kw /11 Kwelectric Vehicle Charging Station Home Wallbox AC EV Charger Single Phase or 3three Phase

Type 2 Wall-Mounted Electric Car Charging Station 7kw /11 Kwelectric Vehicle Charging Station Home Wallbox AC EV Charger Single Phase or 3three Phase

-

G-View G12W Wholesale Auto Car LED Headlight Bulb High Power H13 H11 9005 H7 H4 Car LED Headlights LED Car Lights

G-View G12W Wholesale Auto Car LED Headlight Bulb High Power H13 H11 9005 H7 H4 Car LED Headlights LED Car Lights

-

New Design Porcelain Round Plates Dinner Set for Wedding and Banquet

New Design Porcelain Round Plates Dinner Set for Wedding and Banquet

-

China 2023 New Design Super Soft 100% Polyester Microfiber Knitted Oversized Decoration Hoodie Blanket

China 2023 New Design Super Soft 100% Polyester Microfiber Knitted Oversized Decoration Hoodie Blanket

-

Handmade Art Creative Materials Thickened White Paper Cup DIY Disposable Handmade Colored Paper Cup

Handmade Art Creative Materials Thickened White Paper Cup DIY Disposable Handmade Colored Paper Cup