Product DescriptionEDUCATIONAL DESKTOP ROBOTIC ARMAI smart visual

sorting teaching solusion system ITEM NO .

ZKBOT-301ED our education Robotic arm It is loaded

below 0.5kgs of 3 axis and 4 axis education robotic arm . More and

more education institutions are buying our education robotic arm,

which allows students to learn the principles of science,

engineering, programming, artificial intelligence and automation,

and improve their technical skills, thinking, creativity, teamwork

and problem-solving skills. They help them advance their future

career path.At present, our company produces 3 types of robotic

arms for teaching, please refer to the following parameters.

Robot weight automatic sorting training system1. Function and

description:1.1 System Composition and Function

Robot weight automatic sorting training system

includes robot technology, sensor detection technology, PLC program

technology, 485modbus communication and other technologies.The

system consists of a combination of various training function

modules, there are Robot module: consists of robot, end clamp,

robot control system and teaching touch screen. robot module:

consists of robot, end clamp, robot control system and teaching

touch screen.Conveyor belt module: The conveyor belt module is

constructed of aluminum alloy profiles, and the belt is installed

for transmission. Sheet metal plates are fixed on both sides of the

belt, and the structure is firm.Technical parameters of conveyor

belt: L 1000mm*W 280mm*H 800mm; maximum speed:>3m/min.A

variety of end clamp modules:grasped by hand, suction cup

etc. PLC main control module: It is mainly composed of PLC

controller, control box, etc. The control ZK3U PLC is used to

control each functional module.Electronic scale module: (1)

Accuracy is 0.1g (2) Support modbus-RTU communication,

readable object weight, balance status.Sensor module: photoelectric

sensors, counting workpieces and positioning.Others: Main control

box, workpieces of different sizes, online communication

lines.Note: The default industrial robot for workstation

applications is ZK-BOT301Ed, and it can also be replaced with

similar load products of the ZEKEEP brand. This device is a

teaching and training display production line and the most typical

mechatronics product. It is developed for colleges and

universities, vocational colleges, and vocational education and

training institutions. It is suitable for industrial robots,

mechatronics, electrical automation, etc. Professional teaching and

training. It is specially designed for teaching and training

purposes on the basis of being close to the industrial production

and manufacturing site, which strengthens the installation and

debugging capabilities of mechatronics.3,System module

introduction:Note:The pictures and photos of each module are for

reference, the shape and size may be slightly different, and

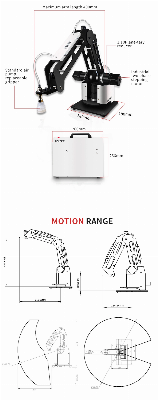

the product matching shall prevail.3.1 Robot ModuleThe module

adopts ZK-BOT301Ed teaching manipulator, robot control box and

teaching touch screen.technical parameter:Dimensions (LxWxH)

1700X1200X750mm Bottom shape: adjustable feet and rollers3.2

Industrial Robot Module The module is

composed of ZK-BOT303Ed teaching manipulator, base, end gripper

tool, robot control system and teach pendant.1.ZK-BOT303Ed*4

sets (1) Manipulator structure: Made of 6061 aluminum

alloy anodized material, equipped with 3 industrial two-phase

stepper motors, 3 1:10 helical gear reducers, 15 arc minutes of

backlash, this manipulator is a 42 stepper motor teaching model

three-axis manipulator, and open the manipulator control protocol

(serial port protocol), users can develop the manipulator twice,

easy to use, which can be used for palletizing, dismantling,

stomping and handling, and can support point-to-point,

point-to-point Straight line, straight line to straight line, etc.,

DO output, DI input, including world coordinates, that is, it can

go straight up and down. The control protocol can also

support openMv, USB industrial cameras, etc. to develop visual

scenes, visual interaction, identify the size and position of

objects and carry them, and connect external devices, which can be

used for small industrial production. This robotic arm is also

equipped with an operating host computer, which is easy to operate

and quick to get started. It supports three major user recipes and

50-step programmable numbers, the maximum telescopic diameter range

is 300mm, and the maximum load is 0.5KG. It is often used in

teaching and test bench development and application.2)The specific

parameters of the robot arm(3) Robot arm control box *4: the main

control adopts 32-bit MCU, and the teaching device adopts

industrial touch screen; the control box is equipped with 2-way DI,

2-way DO switch value, which can be connected to photoelectric

sensors and industrial solenoid valves; teaching The device

supports Chinese operation interface, with joint coordinates and

world coordinates display; the main cont

Related products about A301 Welding Equipment Cobot Robot Small Lifting Equipment for 500g Packing Machine

-

Waste Tyre Plastic Recycling Machinery Machine Tire Crusher Production Line Rubber Crumb Grinding Machine Equipment Tire Shredder

Waste Tyre Plastic Recycling Machinery Machine Tire Crusher Production Line Rubber Crumb Grinding Machine Equipment Tire Shredder

-

Stretch Plastic Blowing Pet Bottle Making Blow Molding Machine Bottles Stretch Automatic Pet Bottle Blowing Machine

Stretch Plastic Blowing Pet Bottle Making Blow Molding Machine Bottles Stretch Automatic Pet Bottle Blowing Machine

-

Waste Plastic Pet Bottle, Water Bottle Flake, PP/HDPE/LDPE PE Film Jumbo Woven Bags Plastic Crusher Machine, Plastic Crushing Washing Recycling Machine

Waste Plastic Pet Bottle, Water Bottle Flake, PP/HDPE/LDPE PE Film Jumbo Woven Bags Plastic Crusher Machine, Plastic Crushing Washing Recycling Machine

-

Type 2 Wall-Mounted Electric Car Charging Station 7kw /11 Kwelectric Vehicle Charging Station Home Wallbox AC EV Charger Single Phase or 3three Phase

Type 2 Wall-Mounted Electric Car Charging Station 7kw /11 Kwelectric Vehicle Charging Station Home Wallbox AC EV Charger Single Phase or 3three Phase

-

G-View G12W Wholesale Auto Car LED Headlight Bulb High Power H13 H11 9005 H7 H4 Car LED Headlights LED Car Lights

G-View G12W Wholesale Auto Car LED Headlight Bulb High Power H13 H11 9005 H7 H4 Car LED Headlights LED Car Lights

-

New Design Porcelain Round Plates Dinner Set for Wedding and Banquet

New Design Porcelain Round Plates Dinner Set for Wedding and Banquet

-

China 2023 New Design Super Soft 100% Polyester Microfiber Knitted Oversized Decoration Hoodie Blanket

China 2023 New Design Super Soft 100% Polyester Microfiber Knitted Oversized Decoration Hoodie Blanket

-

Handmade Art Creative Materials Thickened White Paper Cup DIY Disposable Handmade Colored Paper Cup

Handmade Art Creative Materials Thickened White Paper Cup DIY Disposable Handmade Colored Paper Cup