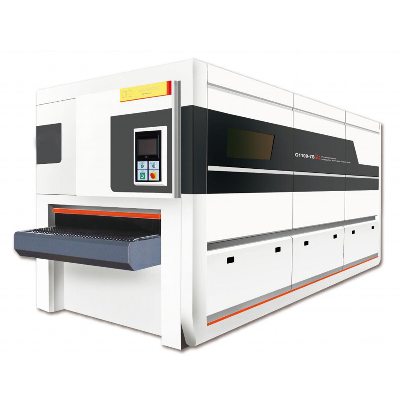

HICAS New Design Woodworking Brush Sanding MachineProduct

DescriptionMax working width1100mmWorking thickness100mmAdjustable

brush speed80-450rpm(can adjust)Screw roller speed80-550 rpm(can

adjust)Conveyor speed2-8m/min(can adjust)Each group of the lifting

power6*0.25kwIntegral lifting power1.1kwDisc brush motor

power2*0.55kwDisc brush motor power2*1.5kwScrew roller motor

power3*2.2kwHorizontal roller motor power2*1.1kwConveyor motor

power2.2kwSwing motor power6*0.2kwTotal power18.9kwScrew roller

number1 setScrew roller diameter420mmBrush plate number in each

group3*3 setBrush tray diameter200mmHorizontal roller number8

setsHorizontal roller diameter350mmVacuuming mouth11*100mmThe wind

speed22-30m/sSuction air11*635m3/hThe weight5450kgThe overall

dimentions4960*1940*2325mmConcumtion powerAbout 6-8kw/hDetailed

PhotosThe structure adopts left and right rolls + 360 degree

discs+front and rear rollerSanding rollersThe sandpaper is more

fully polished from coarse to fine,and the sanding effect can be

more than 90%.The same abrasive belt can be used as unpainted wood

and painted wood .The 1st and 2nd sanding rollers can be oscillated

to the left and right to ensure polishing effect,and the hollowing

plate can be polished to 3-5 mm.The diameter of the roller is

350mm,which is softer and thicker,making the contact surface easier

to polish.Spiral Roller Technology UpgradeSpiral Roller Technology

Upgrade4th & 5th sanding units are rotary discs.These are our

company's innovative design with national patents. Large discs

drives small discs,it can achieve no dead corner

polishing.Especially it has a good polishing effect on grooves.

Besides,these discs adopts quick disassembley technology.The 3rd,

6th and ,7th,8th,9th sanding units adopt spiral rollers to finish

the whole rough and fine sanding .It can sand from front to back

and from back to front. The spiral rollers are equipped with

different sandpapers and they have different sanding rotation

directions.Height Display + Independent Up and DownControl

SystemThe sanding depth of each sanding unit can be adjusted

independently. This can greatly improve the sanding effect.

Independent lifting structure makes the sanding process more

stable.And there is sanding display for the sanding depth,it makes

the operation more visual. (Note:G7 and G9 model can choose memory

function,so that you don't need to adjust it each time for

different workpieces).With memory function,it can automatically

adjust the grinding speed of different plates.Japan SEND

MotorGermany Siemens Electric

applianceTaiwan Liteon Frequency

converterGermany Continental BeltTaiwan ZhouYi ReducerTaiwan HIWIN Guide

bearinAdvantages: The sanding strength of each

sanding unit can be adjusted independently, it can be adjusted

slightly according to theproduct process to ensure the max

combination between sanding rollers and workpiece. This can greatly

improve the sanding effect. Independent lifting structure makes the

sanding process more stable.And there is sanding display for the

sanding depth,it makes the operation more visual. ( there is

optional memory function ,so that you don't need to adjust it each

time for different workpieces).The speed of each sanding unit can

be adjusted independently, it can improve the sanding quality

effectively, and it can prevent damage to the shape and paint

leakage.Each sanding unit cooperates with the swing system ,it

makes the working range wider and more uniform, and it can avoid

scratches caused by long-time sanding on one position.Each sanding

unit is equipped with a humanized pulling design , which makes it

easier toreplace consumables.Each sanding unit is removable .This

structure is more portable to replace the sanding paper and it is

convenient for maintenance.Large diameter sanding roller structure

, matched with high quality sand paper ,Mexico sisal, softer and

flexible, and it is easier to sand the complex design products.

Final Product Packaging & ShippingCertificationsCompany

Profile1. We have our own woodworking machinery

factory. 2. 8 years exportation experience, have

customers in more than 40 countries. 3. Engineer team

with +20 years experience.4. Diamond supplier in

made-in-china.5. Our services Pre-sales

service: To provide customers with the best on-site solutions

with the best products and technologies. In order to better serve

our customers, we have established a complete pre-sales

service support system to provide the most suitable models

according to customer needs. Equipment and solutions, together with

customers to discuss and improve the customer's production process,

processing technology problems. After-sales

service: HICAS after-sales customer service team, responsive.

We can solve various problems for customers in the shortest

time. Tracking service: We track and record

the equipment purchased by each customer and return to it

regularly. Understand customer usage and improve feedback and

feedback, and strive to be responsive to e

Related products about Hicas G7-1300 Woodworking Automatic Brush Sanding Machine for Wood Door Floor

-

Waste Tyre Plastic Recycling Machinery Machine Tire Crusher Production Line Rubber Crumb Grinding Machine Equipment Tire Shredder

Waste Tyre Plastic Recycling Machinery Machine Tire Crusher Production Line Rubber Crumb Grinding Machine Equipment Tire Shredder

-

Stretch Plastic Blowing Pet Bottle Making Blow Molding Machine Bottles Stretch Automatic Pet Bottle Blowing Machine

Stretch Plastic Blowing Pet Bottle Making Blow Molding Machine Bottles Stretch Automatic Pet Bottle Blowing Machine

-

Waste Plastic Pet Bottle, Water Bottle Flake, PP/HDPE/LDPE PE Film Jumbo Woven Bags Plastic Crusher Machine, Plastic Crushing Washing Recycling Machine

Waste Plastic Pet Bottle, Water Bottle Flake, PP/HDPE/LDPE PE Film Jumbo Woven Bags Plastic Crusher Machine, Plastic Crushing Washing Recycling Machine

-

Type 2 Wall-Mounted Electric Car Charging Station 7kw /11 Kwelectric Vehicle Charging Station Home Wallbox AC EV Charger Single Phase or 3three Phase

Type 2 Wall-Mounted Electric Car Charging Station 7kw /11 Kwelectric Vehicle Charging Station Home Wallbox AC EV Charger Single Phase or 3three Phase

-

G-View G12W Wholesale Auto Car LED Headlight Bulb High Power H13 H11 9005 H7 H4 Car LED Headlights LED Car Lights

G-View G12W Wholesale Auto Car LED Headlight Bulb High Power H13 H11 9005 H7 H4 Car LED Headlights LED Car Lights

-

New Design Porcelain Round Plates Dinner Set for Wedding and Banquet

New Design Porcelain Round Plates Dinner Set for Wedding and Banquet

-

China 2023 New Design Super Soft 100% Polyester Microfiber Knitted Oversized Decoration Hoodie Blanket

China 2023 New Design Super Soft 100% Polyester Microfiber Knitted Oversized Decoration Hoodie Blanket

-

Handmade Art Creative Materials Thickened White Paper Cup DIY Disposable Handmade Colored Paper Cup

Handmade Art Creative Materials Thickened White Paper Cup DIY Disposable Handmade Colored Paper Cup