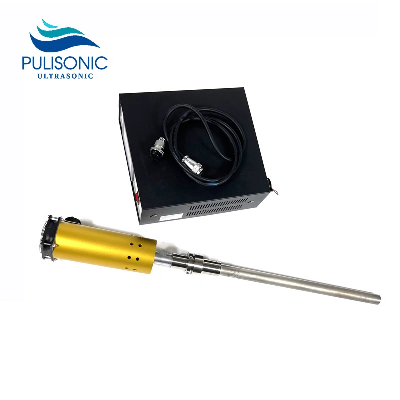

Basic Info.Model NO.PLS-HLCSB1500After-sales ServiceOnline

SupportWarrantyOne YearTypeTubular ReactorMaterialTitanium

AlloyCapacity50-100LStructureSingle TubePressureUltrasonicAgitator

ModelCombined AgitatorTower Reactor TypeBubble Tower

ReactorHeatingElectric HeatingHeat Transfer

StructureCombinedAutomatic

GradeSemi-AutomaticConditionNewApplicationChemical ReactorProduct

NameUltrasonic Probe SonicatorKeywordUltrasonic Homogenizer

ProbeUsageMixing and Extraction DeviceItem NameUltrasonic Reactor

BiodieselFuntionHigh EfficiencyTrademarkPULISONICTransport

PackageWooden BoxSpecification1500WOriginFoshan, ChinaHS

Code8543709990Product Description Ultrasonic Probe Sonicator

Chemical Reactor is also called Ultrasonic Homogenizer Probe

vibrating rod. In terms of industrial application, the use of

ultrasonic vibrating rod for dispersion, extraction, cleaning,

chemical reaction, water treatment and so on is a very mature and

widely used technology.Performance characteristics,Suitable for

various high-power industrial liquid treatment, such as

homogenization, emulsification, dispersion, depolymerization and

wet grinding (particle size reduction), cell crushing and

disintegration, extraction, degassing and sonochemical

processes;Market application:*Traditional Chinese medicine

extraction: refers to the ultrasonic crushing (crushing) of

traditional Chinese medicine cells to achieve efficient extraction

of useful substances. Compared with the conventional extraction

technology, ultrasonic assisted extraction is fast, cheap,

efficient, safe, low cost and wide applicability.*Biodiesel

production: preparing bio oil diesel mixed emulsion by ultrasonic

emulsification is actually dispersing bio oil beads into another

immiscible diesel liquid. Compared with other technologies, the

droplets can be dispersed fine and narrow, high efficiency, good

dispersion effect, and can increase the stability of

emulsion.*Ultrasonic catalysis: the application of ultrasonic to

the catalytic reaction process can simulate the high temperature

and high pressure reaction in the reactor at the micro scale,

providing a very special physical and chemical environment for the

catalytic reaction that is difficult or impossible to achieve under

general conditions, so that the catalytic reaction can be carried

out in a mild environment. It can further improve the reaction

speed, shorten the reaction time and improve the yield of the

target product. The main applications are catalysis on metal

surface, phase transfer catalysis and enzyme catalysis.*Sewage

treatment: in the process of sewage treatment, the cavitation

effect of ultrasonic has a strong ability to degrade organic

matter, and the degradation speed is very fast, which makes it

possible to degrade harmful organic matter in water, so as to

realize the purpose of ultrasonic sewage treatment.*Ultrasonic

dispersion: refers to the process of dispersing and reuniting the

particles in the liquid through the "cavitation" effect of

ultrasonic in the liquid. Ultrasonic dispersion can be divided into

emulsion dispersion (liquid-liquid dispersion) and suspension

dispersion (solid-liquid dispersion), which has been applied in

many fields. The application of ultrasonic wave to the dispersion

of suspension also includes the dispersion of titanium oxide into

water or solvent in the coating industry, and the dispersion of

dyes into molten paraffin; The dispersion of drug particles in the

pharmaceutical industry and the dispersion of powder emulsion in

the food

industry.TypePLS-HLCSB1000PLS-HLCSB1500PLS-HLCSB2000Frequency20KHz20KHz20KHzPower1000W1500W2000W

Related products about 20kHz Titanium Alloy Ultrasonic Probe Sonicator and Generator for Ultrasound Biodiesel Reactor

-

Waste Tyre Plastic Recycling Machinery Machine Tire Crusher Production Line Rubber Crumb Grinding Machine Equipment Tire Shredder

Waste Tyre Plastic Recycling Machinery Machine Tire Crusher Production Line Rubber Crumb Grinding Machine Equipment Tire Shredder

-

Stretch Plastic Blowing Pet Bottle Making Blow Molding Machine Bottles Stretch Automatic Pet Bottle Blowing Machine

Stretch Plastic Blowing Pet Bottle Making Blow Molding Machine Bottles Stretch Automatic Pet Bottle Blowing Machine

-

Waste Plastic Pet Bottle, Water Bottle Flake, PP/HDPE/LDPE PE Film Jumbo Woven Bags Plastic Crusher Machine, Plastic Crushing Washing Recycling Machine

Waste Plastic Pet Bottle, Water Bottle Flake, PP/HDPE/LDPE PE Film Jumbo Woven Bags Plastic Crusher Machine, Plastic Crushing Washing Recycling Machine

-

Type 2 Wall-Mounted Electric Car Charging Station 7kw /11 Kwelectric Vehicle Charging Station Home Wallbox AC EV Charger Single Phase or 3three Phase

Type 2 Wall-Mounted Electric Car Charging Station 7kw /11 Kwelectric Vehicle Charging Station Home Wallbox AC EV Charger Single Phase or 3three Phase

-

G-View G12W Wholesale Auto Car LED Headlight Bulb High Power H13 H11 9005 H7 H4 Car LED Headlights LED Car Lights

G-View G12W Wholesale Auto Car LED Headlight Bulb High Power H13 H11 9005 H7 H4 Car LED Headlights LED Car Lights

-

New Design Porcelain Round Plates Dinner Set for Wedding and Banquet

New Design Porcelain Round Plates Dinner Set for Wedding and Banquet

-

China 2023 New Design Super Soft 100% Polyester Microfiber Knitted Oversized Decoration Hoodie Blanket

China 2023 New Design Super Soft 100% Polyester Microfiber Knitted Oversized Decoration Hoodie Blanket

-

Handmade Art Creative Materials Thickened White Paper Cup DIY Disposable Handmade Colored Paper Cup

Handmade Art Creative Materials Thickened White Paper Cup DIY Disposable Handmade Colored Paper Cup