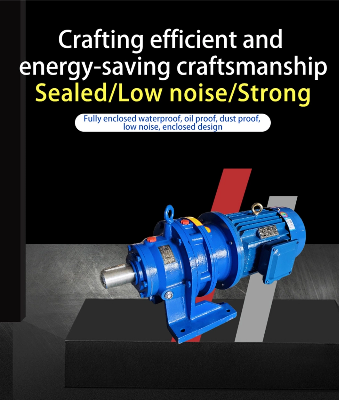

Cycloid pin wheel reducer is used for flange installation in mining

industryFactory advantage1.30 years of history2. Competitive

prices3. Quality AssuranceFour. Fast Delivery Time: General model

about 15-20 days, special model about 30 daysEach process is 100%

tested and 100% selective in raw materials5. Be Efficient6. Low

Noise7. Live Long8. Save Energy9. Slight vibration10. Professional

service/Patience11. Warranty period: 12 months from the date of

deliveryMain Markets: South , Europe, Middle East, Southest Asia,

Africa, etc Components1. Housing: Cast Iron2. Gearset:

Cycloid Wheel & Pin Wheel3. Input Configurations:Equipped with

Electric Motors (AC Motor, Brake Motor, Explosion-proof Motor,

Regulated Speed Motor, Hydraulic Motor)IEC-normalized Motor

FlangeKeyed Solid Shaft Input4. Output Configurations:Keyed Solid

Shaft OutputFeatures1. Large reduction ratio, 1-stage ratio 9~87,

2-stage ratio 121~1849, larger reduction ratio is available by

3-stage or multistage combinations2. High efficiency, the average

efficiency is over 90%3. Compact structure, light weight4. Stable

and reliable operation, low noise5. Long service lifeWHY

CHOOSE US ?1.We are professional electric

motor manufacture for 20 years since 1996.2.We have best

quality materials to make our electric motors best

performance.3.Our products are 100% brand new , 100% cooper wire ,

100% output.4.We have advanced and automated machines such as high

speed punching machines, swing punching machines, machines to form

the rotors ,stators etc. in one piece, automated packing machines

which can produce nice appearance and good performance motors while

decrease the labor cost and mechanical loss .5.We have professional

financial department who are good at calculating and controlling

the cost and capital operation which could make most favorable

prices for our customers.6.We have a strong R&D team, which can

develop and produce products according to drawings or samples

provided by customers.7.We have our own pump and motor production

line, raw materials processing, factory direct sales,

inexpensive.8.We are only 200 kilometers away from Ningbo port,

which is very convenient for export.Product

ParametersModelsPowerRatioMax. TorqueOutput Shaft Dia.Input Shaft

Dia.1

StageX2(B0/B12)0.37~1.59~87150Φ25(Φ30)Φ15X3(B1/B15)0.55~2.29~87250Φ35Φ18X4(B2/B18)0.75~4.09~87500Φ45Φ22X5(B3/B22)1.5~7.59~871,000Φ55Φ30X6(B4/B27)2.2~119~872,000Φ65(Φ70)Φ35X73.0~119~872,700Φ80Φ40X8(B5/B33)5.5~18.59~874,500Φ90Φ45X9(B6/B39)7.5~309~877,100Φ100Φ50

X10(B7/B45)15~459~8712,000Φ110Φ55X11(B8/B55)18.5~559~8720,000Φ130Φ702

StageX32(B10)0.25~0.55121~1849-Φ35Φ15X42(B20/B1812)0.37~0.75121~1849-Φ45Φ15X53(B31/B2215)0.55~1.5121~1849-Φ55Φ18X63(B41/B2715)0.75~2.2121~1849-Φ65(Φ70)Φ18X64(B42/B2718)0.75~2.2121~1849-Φ65(Φ70)Φ22X741.1~3.0121~1849-Φ80Φ22X84(B52/B3318)1.5~4.0121~1849-Φ90Φ22X85(B53/B3322)2.2~5.5121~1849-Φ90Φ30X95(B63/B3922)3.0~7.5121~1849-Φ100Φ30X106(B74/B4527)4.0~11121~1849-Φ110Φ35X117(B84/B5527)4.0~15121~1849-Φ130Φ40(Φ35)If

there is no other request in the order or agreement, terminal box

standard position is at the right side of the frame; data

above may be changed without prior notice.

1.BFlange9.Key17.Rear

endshield25.Terminal box

cover33.Brasslug2.B4Flange10.Rotor18.Fan26.Screw 3.Front

endshield11.Stator19.Fan cowl27.Earth mark 4.Shaft

cover12.Pedestal20.FancowlScrew28.Brass washer 5.Spring

washer13.Pedestal bolt21.Fan clamp29.Deductioncap 6.Vring Oil

seal14.Nameplate22.Cable gland30.Brassnet 7.Bolt15.Main

frame23.Terminal box base31.Termiani board 8.Bearing16.Wave

washer24.Gasket32.Leather washer /* January 22, 2024 19:08:37

*/!function(){function s(e,r){var

a,o={};try{e&&e.split(",").forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

Related products about Cycloid Pin Wheel Reducer Is Used for Flange Installation in Mining Industry

-

Waste Tyre Plastic Recycling Machinery Machine Tire Crusher Production Line Rubber Crumb Grinding Machine Equipment Tire Shredder

Waste Tyre Plastic Recycling Machinery Machine Tire Crusher Production Line Rubber Crumb Grinding Machine Equipment Tire Shredder

-

Stretch Plastic Blowing Pet Bottle Making Blow Molding Machine Bottles Stretch Automatic Pet Bottle Blowing Machine

Stretch Plastic Blowing Pet Bottle Making Blow Molding Machine Bottles Stretch Automatic Pet Bottle Blowing Machine

-

Waste Plastic Pet Bottle, Water Bottle Flake, PP/HDPE/LDPE PE Film Jumbo Woven Bags Plastic Crusher Machine, Plastic Crushing Washing Recycling Machine

Waste Plastic Pet Bottle, Water Bottle Flake, PP/HDPE/LDPE PE Film Jumbo Woven Bags Plastic Crusher Machine, Plastic Crushing Washing Recycling Machine

-

Type 2 Wall-Mounted Electric Car Charging Station 7kw /11 Kwelectric Vehicle Charging Station Home Wallbox AC EV Charger Single Phase or 3three Phase

Type 2 Wall-Mounted Electric Car Charging Station 7kw /11 Kwelectric Vehicle Charging Station Home Wallbox AC EV Charger Single Phase or 3three Phase

-

G-View G12W Wholesale Auto Car LED Headlight Bulb High Power H13 H11 9005 H7 H4 Car LED Headlights LED Car Lights

G-View G12W Wholesale Auto Car LED Headlight Bulb High Power H13 H11 9005 H7 H4 Car LED Headlights LED Car Lights

-

New Design Porcelain Round Plates Dinner Set for Wedding and Banquet

New Design Porcelain Round Plates Dinner Set for Wedding and Banquet

-

China 2023 New Design Super Soft 100% Polyester Microfiber Knitted Oversized Decoration Hoodie Blanket

China 2023 New Design Super Soft 100% Polyester Microfiber Knitted Oversized Decoration Hoodie Blanket

-

Handmade Art Creative Materials Thickened White Paper Cup DIY Disposable Handmade Colored Paper Cup

Handmade Art Creative Materials Thickened White Paper Cup DIY Disposable Handmade Colored Paper Cup