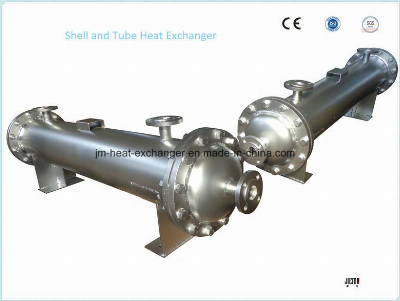

Stainless Steel Shell and Tube Heat

Exchanger Descripition:shell and tube heat exchanger is

a class of heat exchanger designs. It is the most common type

of heat exchanger in oil refineries and other large chemical

processes, and is suited for higher-pressure applications. As its

name implies, this type of heat exchanger consists of a shell

(a large pressuere vessel) with a bundle of tubes inside it.

One fluid runs through the tubes, and another fluid flows over the

tubes (through the shell) to transfer heat between the two fluids.

The set of tubes is called a tube bundle, and may be composed

of several types of tubes: plain, longitudinally finned, etc.So,it

is also called Tubular Heat

Exchanger.

Theory and Application:Two fluids, of different starting

temperatures, flow through the heat exchanger. One flows through

the tubes (the tube side) and the other flows outside the tubes but

inside the shell (the shell side). Heat is transferred from one

fluid to the other through the tube walls, either from tube side to

shell side or vice versa. The fluids can be either liquids or gases

on either the shell or the tube side. In order to transfer heat

efficiently, a large heat transfer area should be used,

leading to the use of many tubes. In this way, waste heat can be

put to use. This is an efficient way to conserve energy.Shell and

tube heat exchanger design:Counter current heat exchangers are most

efficient because they allow the highest log mean temperature

difference between the hot and cold streams. Many companies however

do not use single pass heat exchangers because they can break

easily in addition to being more expensive to build. Often multiple

heat exchangers can be used to simulate the counter current flow of

a single large

exchanger. Please

provide the following working parameters, we will provide you with

professional design and selection Suggestions.Capacity

(Kw/Kcal/h)Hot side medium Cold side medium Flow

rate Flow

rate Inlet

temperature Inlet temperature outlet

temperature outlet temperature Working

pressure Working pressure Allowable prssure

drop Allowable prssure drop

Contact: Seana Web:jm-heat-exchanger.en.made-in-china.com Applications

and uses:1.cooling of hydraulic fluid and oil in engines,

transmissions and hydraulic power packs2.heating other mediums,such

as water,beverager,orange juice and other steam3.they are

extensively applied in chemical industrial,pertroleum and energy

source and etc. Design selection need to provide the following

parameters:The Heat Exchanger Tube Specifications Φ20DNQuantity of

tube passQuantity of heat exchanger tubeQuantity of center raw

tube tube pass flow area(m²)Heat exchanger area(m²)Tube

length(mm)1500200030004500600015911550.0030 1.4 1.9 2.8 21913370.0066 3.1 4.1 6.2 27316590.0131 6.1 8.2 12.3 18.4 24.5 25680.0056 5.3 7.0 10.6 15.8 21.1 325199110.0199 9.3 12.4 18.7 28.0 37.3 288100.0088 8.3 11.1 16.6 24.9 33.2 468110.0034 6.4 8.5 12.8 19.2 25.6 4001174140.0350 16.4 21.9 32.8 49.2 65.8 2164150.0165 15.5 20.6 30.9 46.4 61.8 4146140.0073 13.8 18.3 27.5 41.3 55.0 4501237170.0477 22.3 29.8 44.7 67.0 89.3 2220160.0221 20.7 27.8 41.5 62.2 82.9 4200160.0101 18.8 25.1 37.7 56.5 75.4 5001275190.0553 34.6 51.8 77.8 103.7 2256180.0257 32.2 48.3 72.4 96.5 4222180.0112 27.9 41.8 62.8 83.7 The

Heat Exchanger Tube Specifications Φ25DNQuantity of tube

passQuantity of heat exchanger tubeQuantity of center raw

tube tube pass flow area(m²)Heat exchanger area(m²)Tube

length(mm)1500200030004500600015911130.0038 1.3 1.7 2.6 21912550.0087 2.9 3.9 5.6 27313860.0132 4.5 6.0 9.0 13.4 17.9 23270.0055 3.8 5.0 7.5 11.3 15.1 32515790.0197 6.7 9.0 13.4 20.1 26.9 25690.0097 6.6 8.8 13.2 19.8 26.4 44090.0035 4.7 6.3 9.4 14.1 18.8 400198120.0339 11.5 15.4 23.1 34.6 46.2 294110.0163 11.1 14.8 22.1 33.2 44.3 476110.0066 9.0 11.9 17.9 26.9 35.8 4501135130.0468 15.9 21.2 31.8 47.7 63.6 2126120.0218 14.8 19.8 29.7 44.5 59.4 4106130.0092 12.5 16.7 25.0 37.5 50.0 5001174140.0603 27.3 41.0 61.5 82.0 2164150.0284 25.8 38.6 58.0 77.3 4144150.0125 22.6 33.9 50.9 67.9 About

WarrantyWe promise 10 year guarantee, all reasonable relevant cost

will be undertaken by us in the first year if our heat exchanger

fail to work due to quality problem,only the free repairing

operation guide is available in the rest of the

9 years via E-mail /Fax/PhoneCompany Profiles : Guangzhou

Jiema is focus on the heat exchanger and spare parts manufacturer

since 2005 with over 200 workers . Welcome to visit us

: jm-heat-exchanger.en.made-in-china.comWe also provided

technical service such as technical consultation, equipment update,

capacity expansion scheme,

Related products about Stainless Steel Shell and Tube Heat Exchanger for Thermal Oil and Water

-

Waste Tyre Plastic Recycling Machinery Machine Tire Crusher Production Line Rubber Crumb Grinding Machine Equipment Tire Shredder

Waste Tyre Plastic Recycling Machinery Machine Tire Crusher Production Line Rubber Crumb Grinding Machine Equipment Tire Shredder

-

Stretch Plastic Blowing Pet Bottle Making Blow Molding Machine Bottles Stretch Automatic Pet Bottle Blowing Machine

Stretch Plastic Blowing Pet Bottle Making Blow Molding Machine Bottles Stretch Automatic Pet Bottle Blowing Machine

-

Waste Plastic Pet Bottle, Water Bottle Flake, PP/HDPE/LDPE PE Film Jumbo Woven Bags Plastic Crusher Machine, Plastic Crushing Washing Recycling Machine

Waste Plastic Pet Bottle, Water Bottle Flake, PP/HDPE/LDPE PE Film Jumbo Woven Bags Plastic Crusher Machine, Plastic Crushing Washing Recycling Machine

-

Type 2 Wall-Mounted Electric Car Charging Station 7kw /11 Kwelectric Vehicle Charging Station Home Wallbox AC EV Charger Single Phase or 3three Phase

Type 2 Wall-Mounted Electric Car Charging Station 7kw /11 Kwelectric Vehicle Charging Station Home Wallbox AC EV Charger Single Phase or 3three Phase

-

G-View G12W Wholesale Auto Car LED Headlight Bulb High Power H13 H11 9005 H7 H4 Car LED Headlights LED Car Lights

G-View G12W Wholesale Auto Car LED Headlight Bulb High Power H13 H11 9005 H7 H4 Car LED Headlights LED Car Lights

-

New Design Porcelain Round Plates Dinner Set for Wedding and Banquet

New Design Porcelain Round Plates Dinner Set for Wedding and Banquet

-

China 2023 New Design Super Soft 100% Polyester Microfiber Knitted Oversized Decoration Hoodie Blanket

China 2023 New Design Super Soft 100% Polyester Microfiber Knitted Oversized Decoration Hoodie Blanket

-

Handmade Art Creative Materials Thickened White Paper Cup DIY Disposable Handmade Colored Paper Cup

Handmade Art Creative Materials Thickened White Paper Cup DIY Disposable Handmade Colored Paper Cup